i3D® Technology

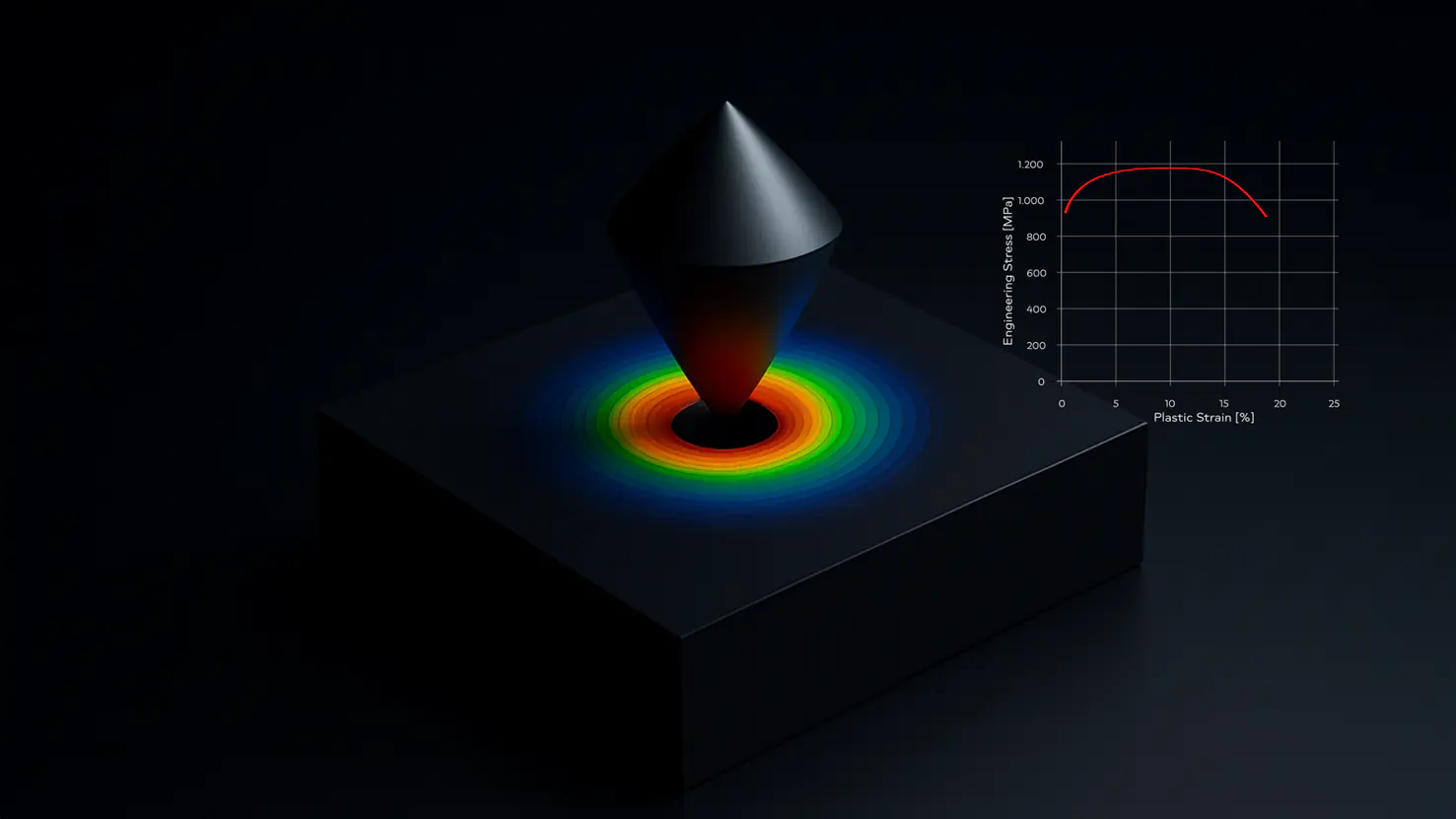

Indentation-based testing for yield and tensile strength on real parts.

i3D® Technologyi3D® Indentation Method per DIN SPEC 4864

The standardized i3D® indentation method is a modern alternative to conventional tensile testing. Key mechanical properties — yield strength RIp0.2, ultimate tensile strength RIm, and plastic flow curves — are determined directly on the component surface, with minimal specimen preparation.

Test workflow

1. Create the test impression: A force-controlled indenter penetrates the metallic surface orthogonally — minimal damage, highly localized.

2. 3D measurement: White-light interferometry captures the impression in high lateral and vertical resolution.

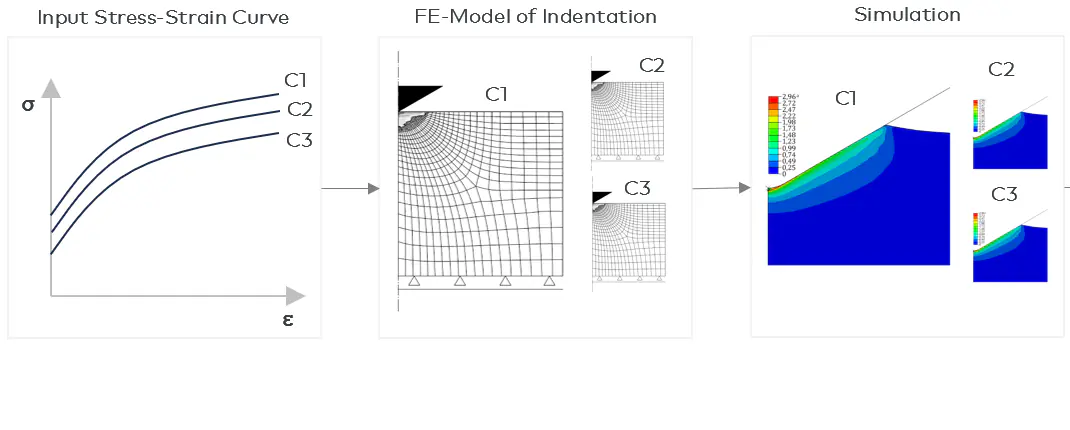

3. Inverse FEM evaluation: An optimization algorithm compares the measured impression geometry with FEM simulations to determine the material’s flow curve.

4. Material properties: The resulting engineering stress–strain curve provides RIp0.2, RIm, ductility, and more — analogous to tensile testing.

Advantages at a glance

- Fast: ~60 seconds per impression

- Minimal preparation: test directly on the component

- Accurate: typically within approx. ±2% to ±10% of tensile testing

- Repeatable: assured via fully automated testing

- Industry 4.0-ready: ideal for serial testing and automation

Comparison with tensile testing

Extensive studies comparing i3D® indentation with conventional tensile tests show deviations commonly below 5%, while cutting test costs by up to 90% and significantly reducing total test time.

This makes i3D® the perfect fit for modern, data-driven materials development, process monitoring, and quality assurance — in the lab or right on the production floor.

Looking for flow-curve input for CAE? See our FEM simulation application. Curious about savings vs. tensile tests? View the cost comparison.

Request a demoExplore i3D® applications

"Material Testing Solutions"