Overview

Imprintec: Inline Quality Assurance for 3D Printing

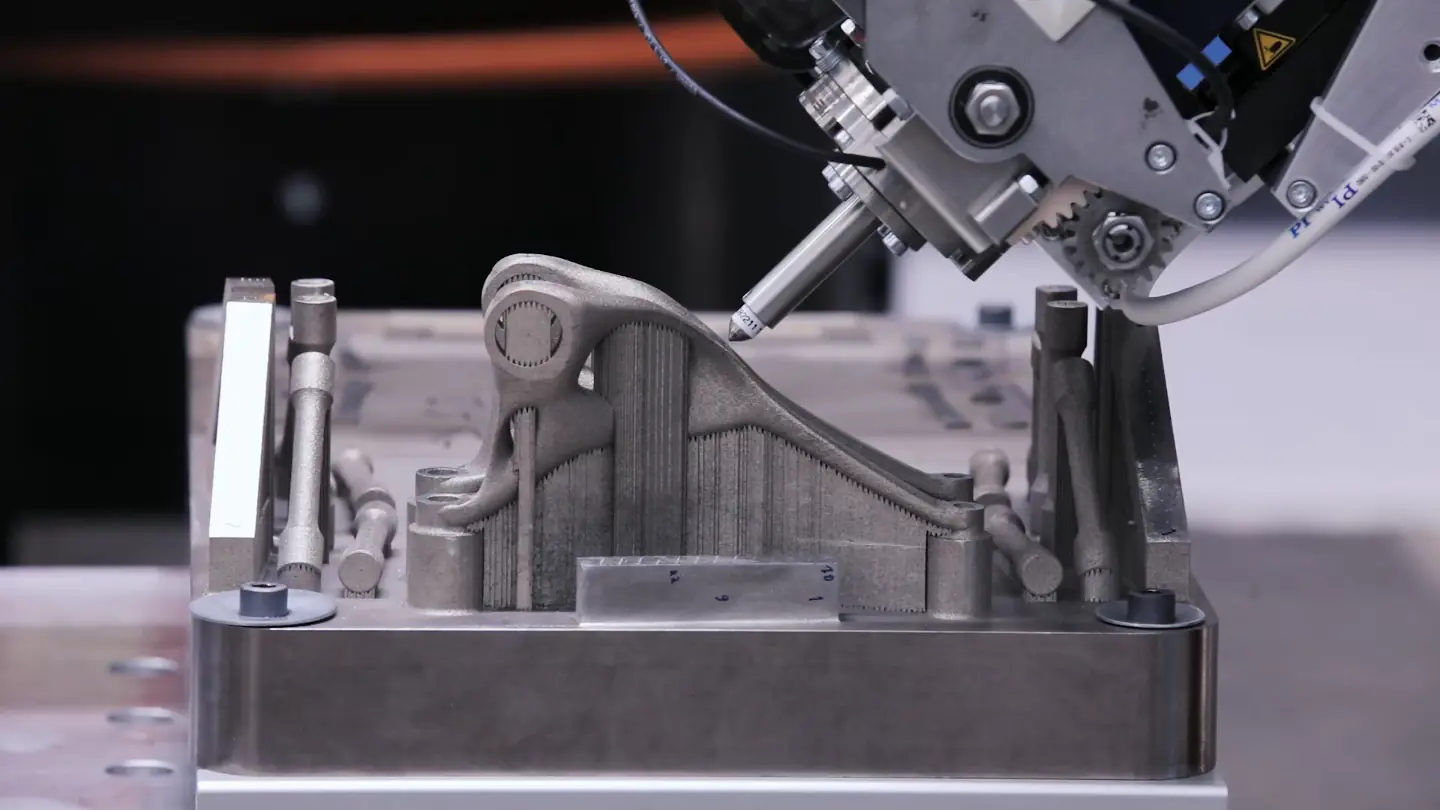

In June 2024, Fraunhofer IPA and Imprintec GmbH achieved a major milestone in automated quality assurance for 3D-printed components. Together, within the BMWK-funded project “Enabl3D”, they developed a robot-assisted inline testing module for process-proximate part evaluation.

Project overview: Enabl3D – efficient quality assurance for 3D-printed parts

The project aimed to develop a cost-effective and reliable inspection method for bionically optimized, resource-efficient 3D-printed components. Partners alongside Imprintec included Fraunhofer IAPT and VisiConsult GmbH.

Combining indentation testing, high-resolution process monitoring, and µCT analysis resulted in a three-stage inspection approach that captures both local material properties and defect locations comprehensively and non-destructively.

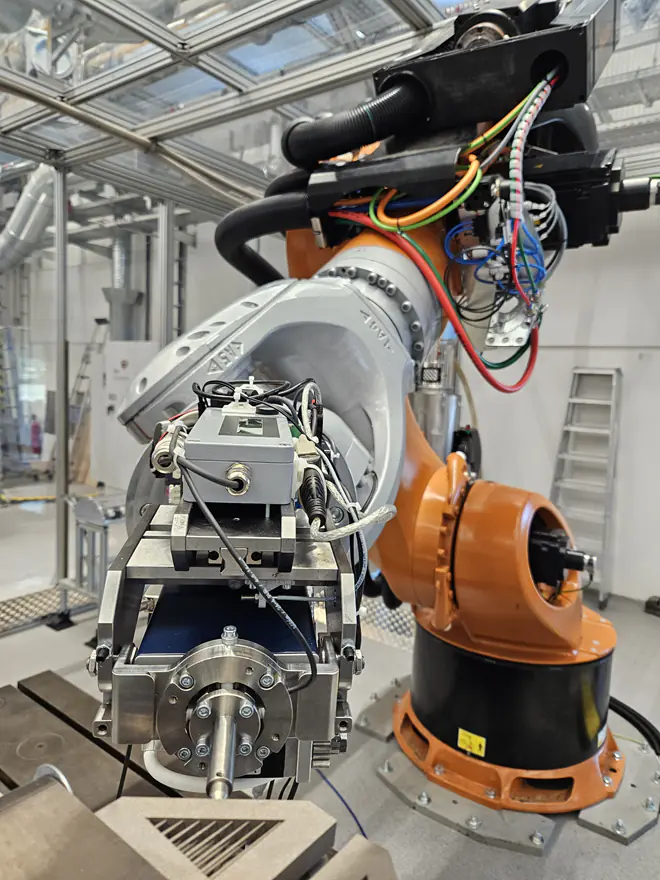

Robot-assisted integration into production

In the sub-project “Integration of hardness measurement technology”, Fraunhofer IPA and Imprintec connected the testing module to a six-axis robot. Testing can thus be performed fully automatically and directly on the production line – without part manipulation or process interruption.

Initial tests on series components confirmed the functionality and added value of the solution: process data, geometric deviations, and mechanical properties can be captured efficiently and linked.

Fields of application & outlook

Additive manufacturing enables sustainable, CO2-saving lightweight solutions – especially in aerospace, automotive, and medical technology. The developed inspection technology provides the required safety and cost-effectiveness to move 3D printing from prototype to series production.

Learn more

Further Applications

"Material Testing Solutions"