High-precision motion control for automated series measurements across parts or sample arrays.

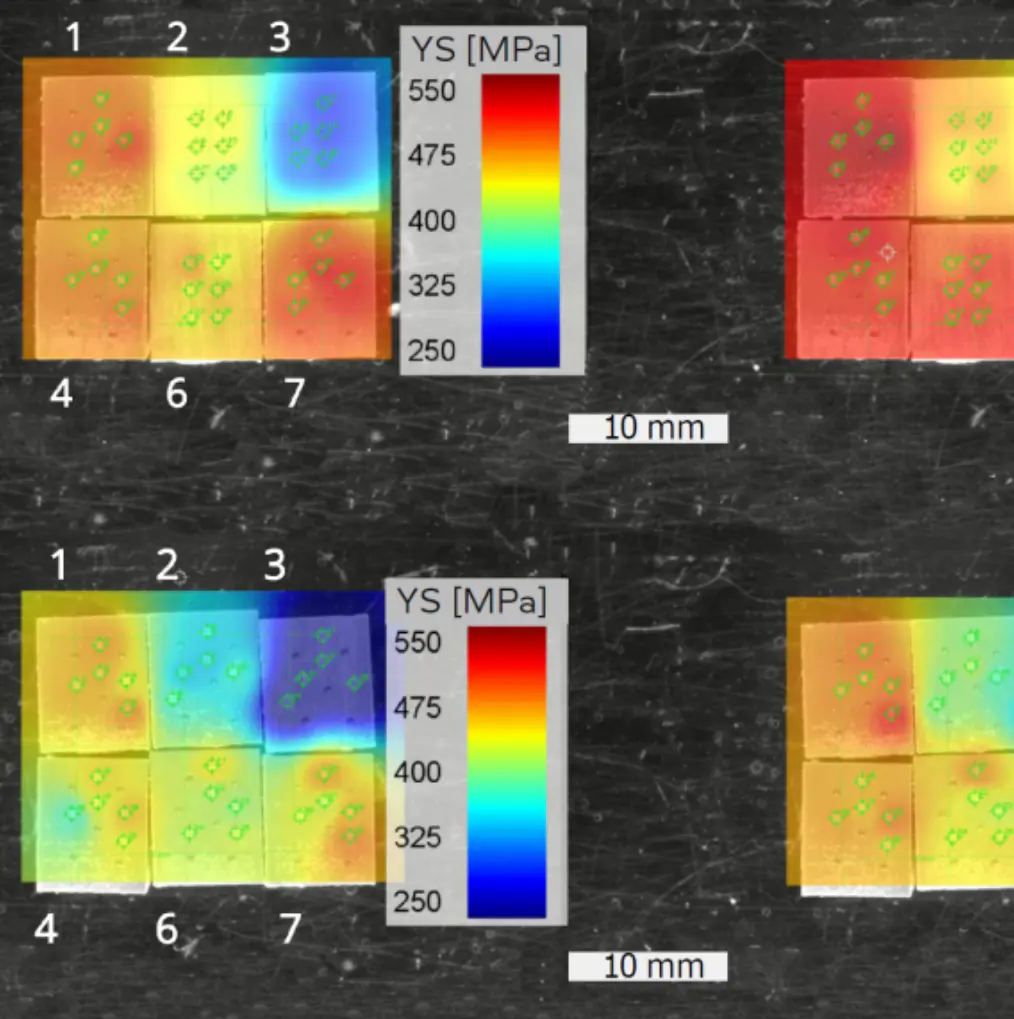

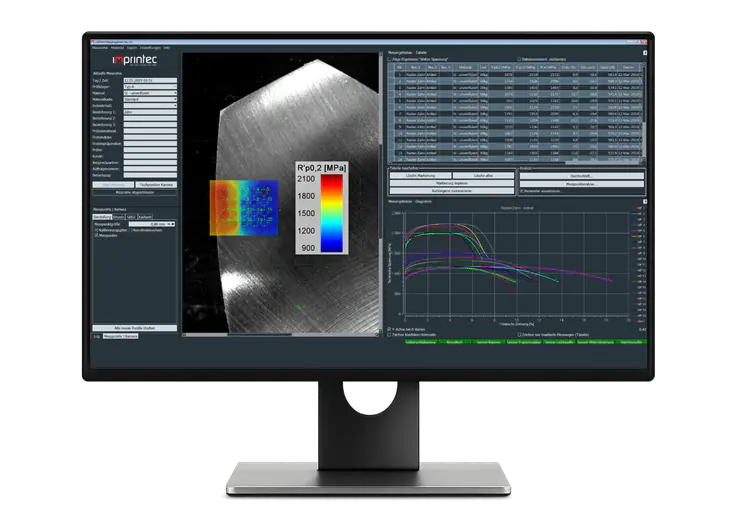

Yield strength RIp0,2, tensile strength RIm and ductility from indentations — i3D®

Fully automated, high-throughput testing for fast analysis of mechanical properties — ideal for parameter studies and alloy development.

Request demo Request quote

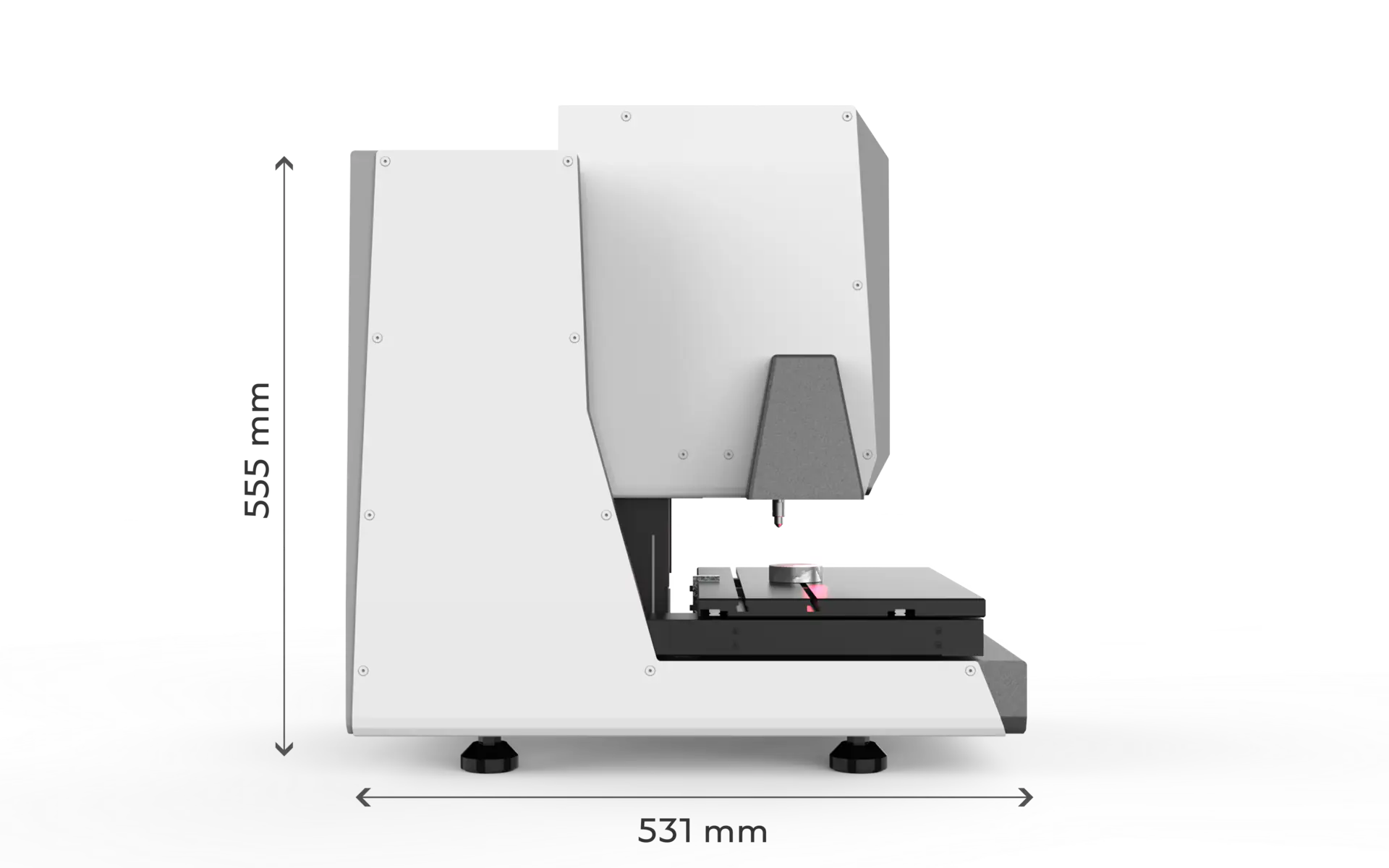

Fully automated workflows via motorized XY cross table and a Z-axis positionable head.

| Function | Description |

|---|---|

| Indentation testing | Testing of metallic materials to determine RIp0,2 (yield strength) and RIm (tensile strength) per DIN SPEC 4864 — no tensile specimen required |

| Measurement time (standard) | Approx. 72 seconds per measurement point |

| Measurement time (high-speed) | Optional: super-speed system with cycle times from approx. 20 seconds per point |

| XY cross table | Automated raster positioning — ideal for multi-point measurements and component mapping |

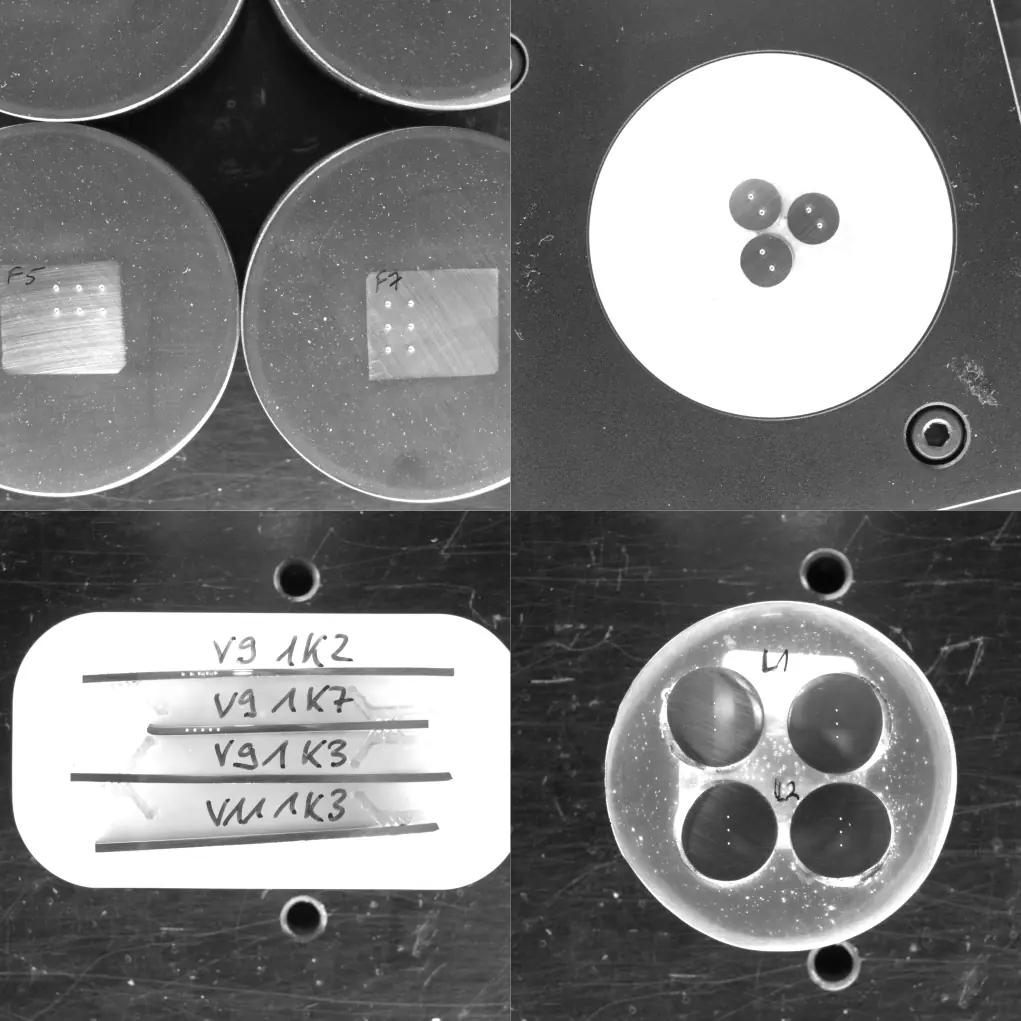

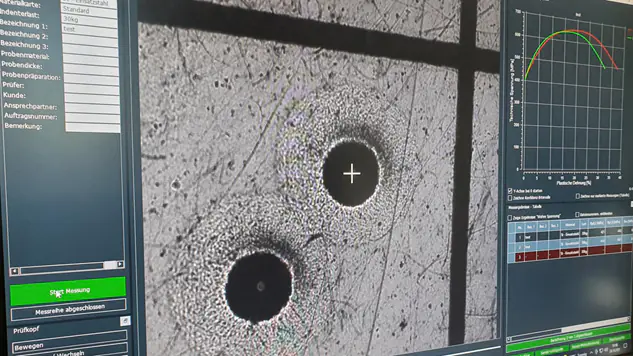

| Overview camera | Visual identification and precise placement of measurement points with full documentation |

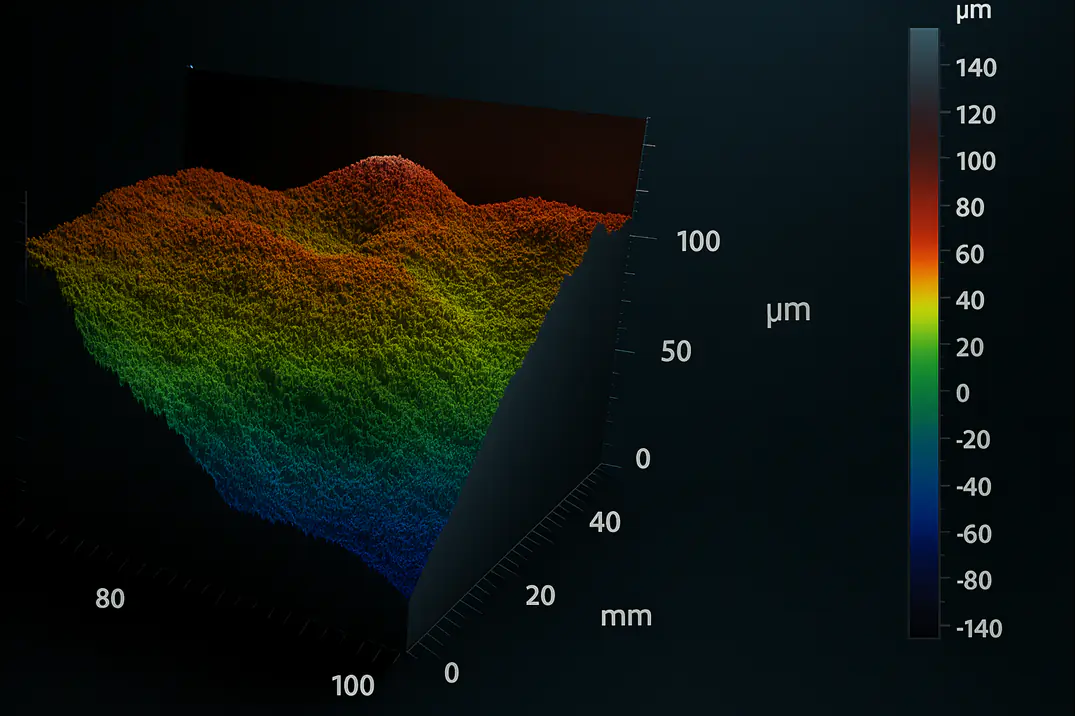

| 3D surface measurement (optional) | White-light interferometry for height maps and detailed topography analysis |

High-precision motion control for automated series measurements across parts or sample arrays.

Image-guided selection and verification of measurement points — for optimal repeatability.

Fully automated multi-point testing across samples or within one component — perfect for serial testing, microstructure or process studies.

Enable the high-precision white-light interferometer for standalone surface metrology.

i3D® across all Imprintec instruments. Inverse FEM models derive stress–strain curves from indentation profiles.

Learn more about inverse FEM analysis

The DIN SPEC 4864 indentation method enables low-damage, precise, and automated determination of yield strength (RIp0,2), tensile strength (RIm), and flow curves — without tensile specimens. A small indent, including the characteristic pile-up, is captured optically in 3D; an inverse finite-element model then evaluates the geometry and delivers strength parameters in minutes. This eliminates elaborate specimen preparation, providing fast, local, and actionable material data — ideal for small components, structured materials, or serial analyses. The approach is cost-efficient, time-saving, and opens new possibilities in R&D and QA.

Learn more about the testing technologyCurrently approx. 16 weeks from order (ex works)

New units

Demo units (subject to availability)

Refurbished units (on request)

Purchase (one-time payment)

Leasing (flexible terms)

3D surface measurement via white-light interferometry (WLI)

Super-speed mode (approx. 20 s cycle time)

Software packages

Explore the complete i3D® series for research, development, and quality assurance.

Peter Zok

Applications – Materials Testing

Imprintec GmbH

15 years of experience in materials testing.

Contact →