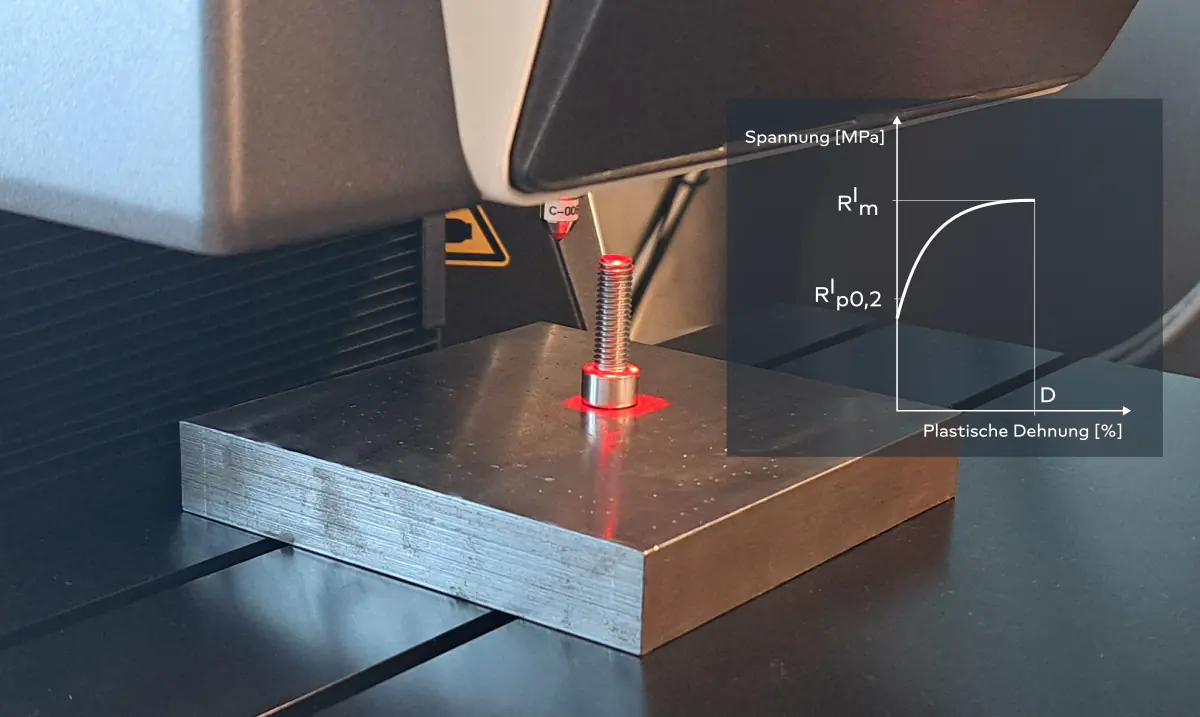

i3D® Application: Screw Testing

The Imprint method provides a non-destructive way to evaluate the mechanical properties of screws and similar components directly on the finished part—without cutting, milling, or standardized specimen preparation.

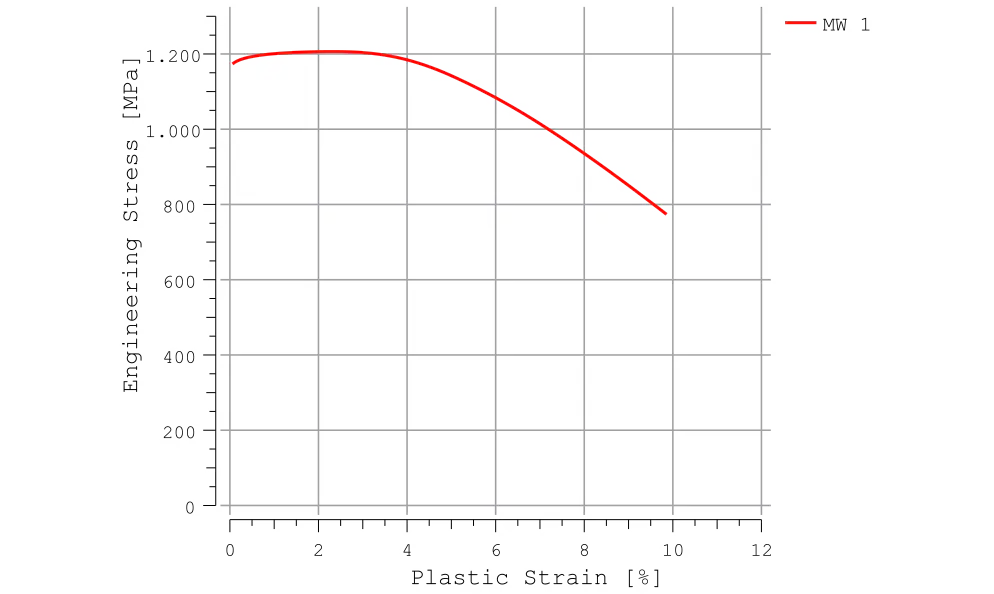

This innovative technique delivers locally resolved plastic stress–strain curves and enables precise determination of: yield strength from indentation (RIp0.2, comparable to tensile testing), ultimate tensile strength from indentation (RIm, comparable to tensile testing), ductility from indentation, and strain hardening.

Unlike conventional hardness testing based on empirical conversions, the Imprint method provides quantitative and reliable mechanical data—even for materials such as austenitic steels, where classic hardness-to-strength correlations often fail.

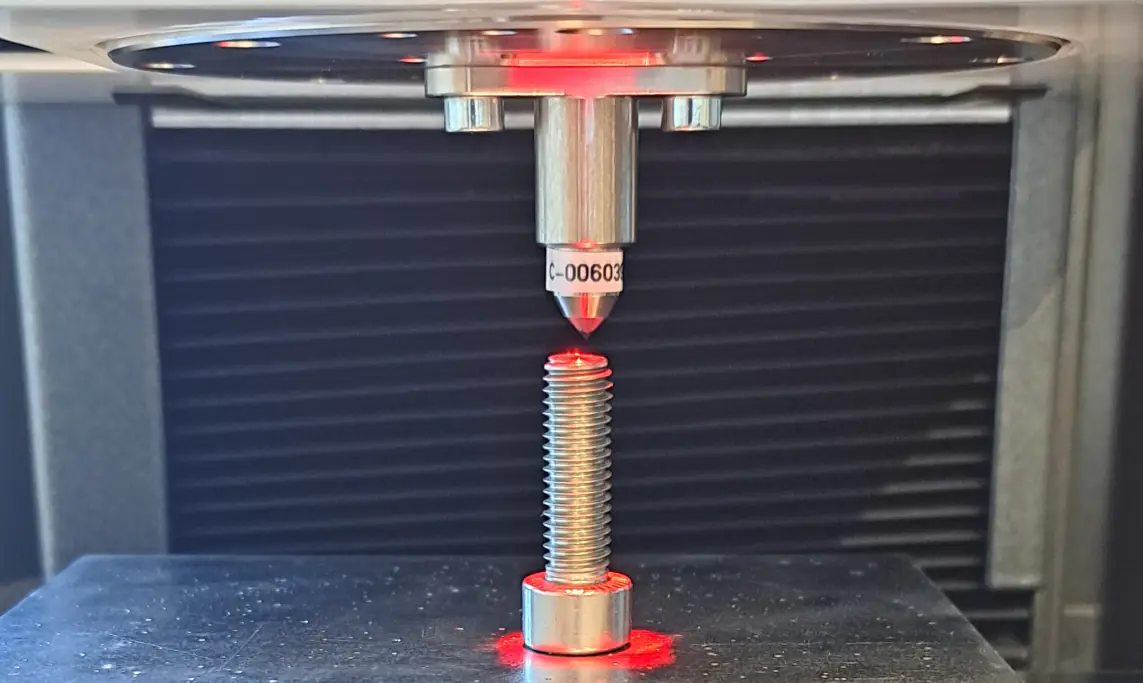

Compared to tensile testing, the method offers cost-efficient and spatially resolved analysis—ideal for critical areas like thread roots, welds, or surface-treated zones.

This makes the method especially valuable for quality assurance, failure investigation, and material development when testing without destroying the part is essential. It opens up new possibilities to validate mechanical performance—even in areas previously inaccessible to conventional test methods.

Practical example: mechanical testing of screws

Mechanical screw testing with i3D®:

The Imprint method offers a non-destructive way to assess mechanical properties directly on the finished component—with no specimen preparation required. This is especially advantageous for complex geometries such as threads.

The technique enables local stress–strain curves with precise determination of comparable strength values (RIp0.2, RIm) as well as statements on ductility and hardening. Even for difficult-to-test materials such as austenitic steels, it provides reliable data where conventional hardness methods fall short.

Ideal for quality assurance, material development, and failure analysis—everywhere non-destructive testing is essential.

Further Applications

"Material Testing Solutions"