Test and compare many samples — spatially resolved.

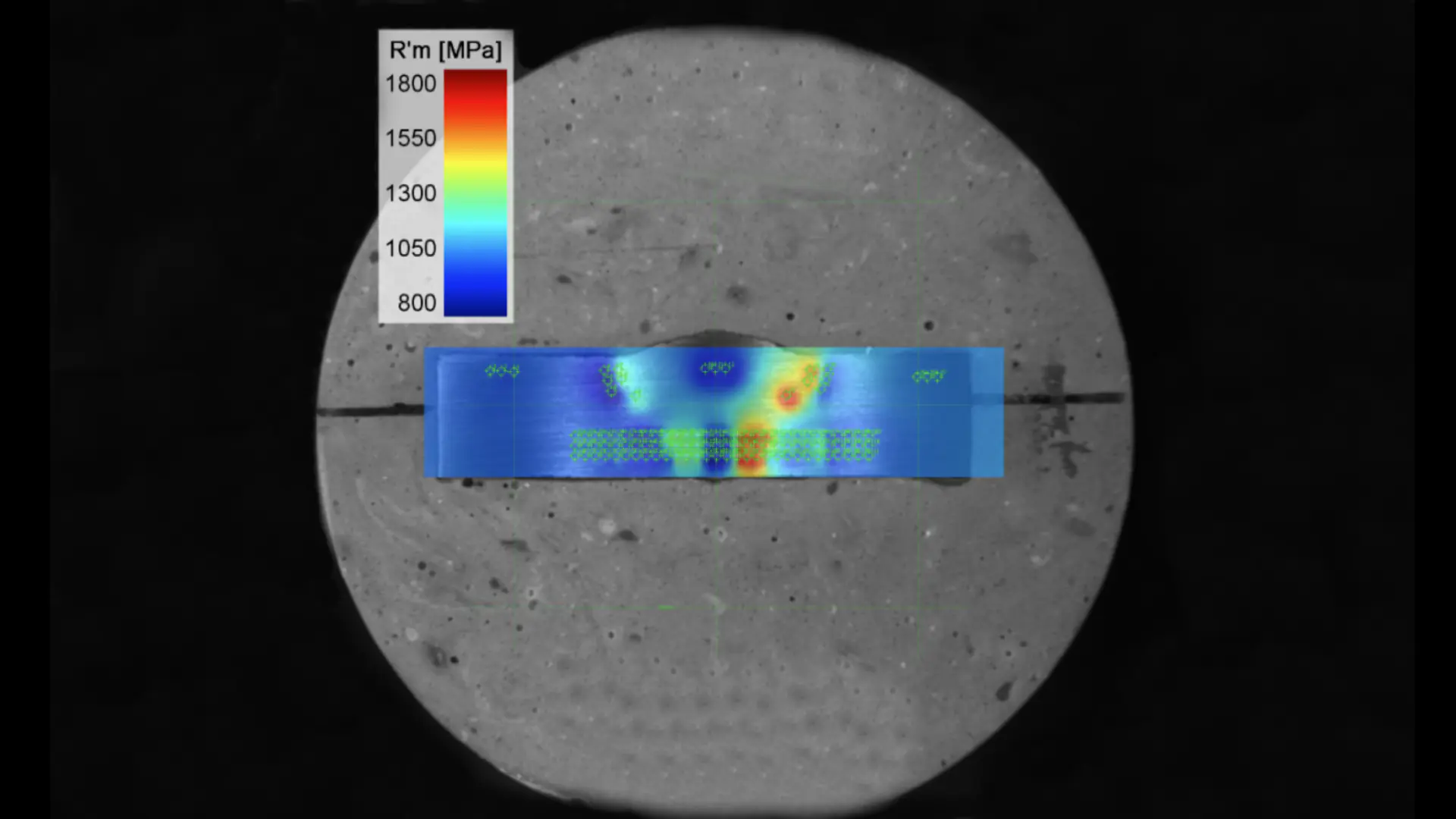

R&D application →i3D® testing enables mechanical materials analysis directly on components and samples — fast, spatially resolved, and low-damage. It’s used across research, quality assurance, and series production.

i3D® gives research teams direct access to stress- and strain-relevant properties on the actual part — ideal for spatially resolved investigations and cost-efficient parameter studies.

Sample testing, parameter studies, multisample screening, weld analysis, characterization of strength gradients and hardening zones.

Affordable access to spatially resolved stress–strain curves — even from a single sample. No elaborate specimen prep or tensile tests required.

Research projects, comparative studies, material characterization, process development.

i3D® supports aerospace R&D with spatially resolved mechanical testing right on the component — ideal for optimizing safety-critical parts.

Alloy development, testing of critical components, weld analysis, surface and edge-zone characterization, parameter studies for additively manufactured parts.

Fast, local mechanical insights without destroying samples. Cost-effective testing for complex R&D questions.

Welds on engine components, turbine blades, structural parts, AM components.

In automotive, i3D® enables targeted investigations of safety-critical structures such as welds or crash zones. The technology delivers spatially resolved data directly on the real component.

Weld seam analysis, mechanical characterization of transition and edge zones, data for finite-element analysis (FEA) and crash simulations.

Strength analysis without elaborate specimen preparation. Local stress–strain data for realistic simulation models.

Body-in-white structures, welds in crash zones, vehicle frames, FE model calibration.

Precise, low-damage testing of very small, safety-critical parts is essential in medtech. i3D® enables QA and materials analysis of implants and functional components — straight from production.

Testing tiny structures, go/no-go analyses, supplier qualification, in-process inspections, implant testing.

Local access even on miniature parts. Measurement of yield and tensile strength on delicate components — fast and without damage.

Pacemakers, implants, surgical tools, micromechanics in medical systems.

i3D® enables mechanical characterization of components and fasteners in research, development, and QA — especially on safety-critical structures.

Testing of fasteners, small parts, ammunition components, alloy development, parameter studies.

Fast, cost-efficient testing with direct access to mechanical properties — local and low-damage.

–

i3D® provides precise insight into the mechanical behavior of very small components — ideal for functional checks, failure analysis, and quality control in electronics.

Component testing, functional inspections, failure analysis, forming-degree characterization, go/no-go evaluation, process optimization.

Cost-efficient, fast testing of tiny structures with detailed mechanical data — ideal for internal QA and optimization.

Connectors, contacts, fine elements in circuits.

Test and compare many samples — spatially resolved.

R&D application →

Local flow curves for realistic simulation models.

R&D application →

Local mechanical properties on weld seams.

R&D application →i3D® testing offers a cost-effective alternative to conventional tensile testing — ideal as a fast, internal QA measure.

Elaborate specimen preparation, high machine costs, time-consuming procedures.

Testing directly on the component, no machining, faster workflows, lower unit costs.

Ideal for in-process testing, supplier evaluations, and internal approvals.