“With i3D® we validate additively manufactured parts quickly and with minimal damage.”

Explore →

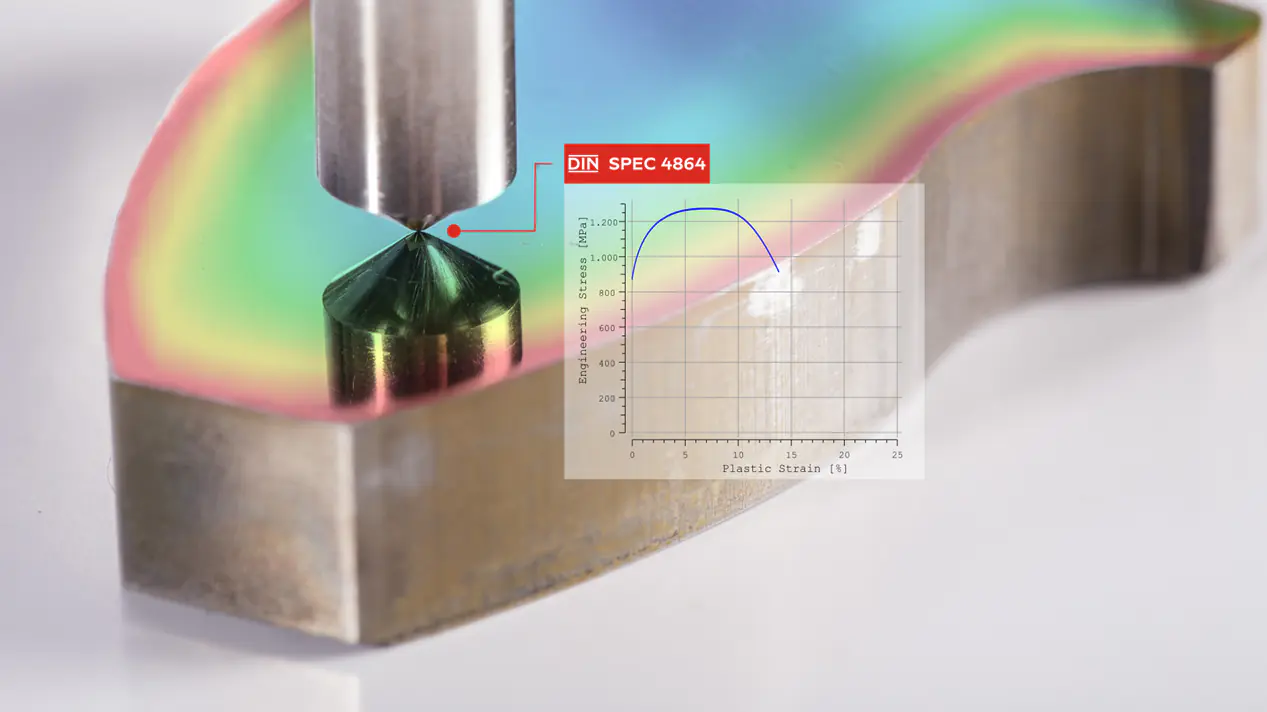

i3D® rethinks mechanical materials testing—especially where conventional tensile testing reaches its limits. Instead of preparing elaborate standard specimens, i3D® enables direct strength testing on the real component—low-damage, precise and fast. With fully automated multi-sample screening, more than 500 stress–strain curves can be captured in a short time—first results are often available within a minute.

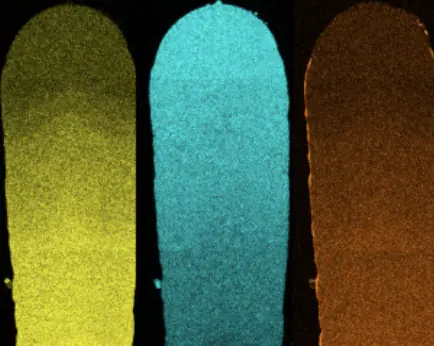

A key advantage: locally resolved testing of mechanical properties makes it possible to capture strength gradients, e.g. in heat-affected zones, surface layers or additively manufactured structures with targeted work hardening. This makes i3D® ideal for research, development and production monitoring.

By eliminating time-consuming specimen preparation, fixtures and machine changeovers, costs are significantly reduced—without compromising on insight or accuracy. i3D® brings new efficiency to materials characterization—right where you need it.

Learn more about the test technology

| Year | Milestone |

|---|---|

| 2017 | Imprintec GmbH founded |

| 2018 | First products launched |

| 2019 | Standardization of the indentation method in DIN SPEC 4864 |

| 2022 | Portfolio expansion: i3D® mBV and i3D® BVR instruments |

| 2024 | Start of international standardization activities (ASTM) |

“With i3D® we validate additively manufactured parts quickly and with minimal damage.”

Explore →

“i3D® enables spatially resolved testing on the smallest additive structures.”

“We use i3D® to optimize and inspect parts efficiently.”

“i3D® accelerates our production control and saves valuable development time.”

“i3D® is essential to our research in additive manufacturing.”

“We rely on i3D® for incoming inspection of complex components.”