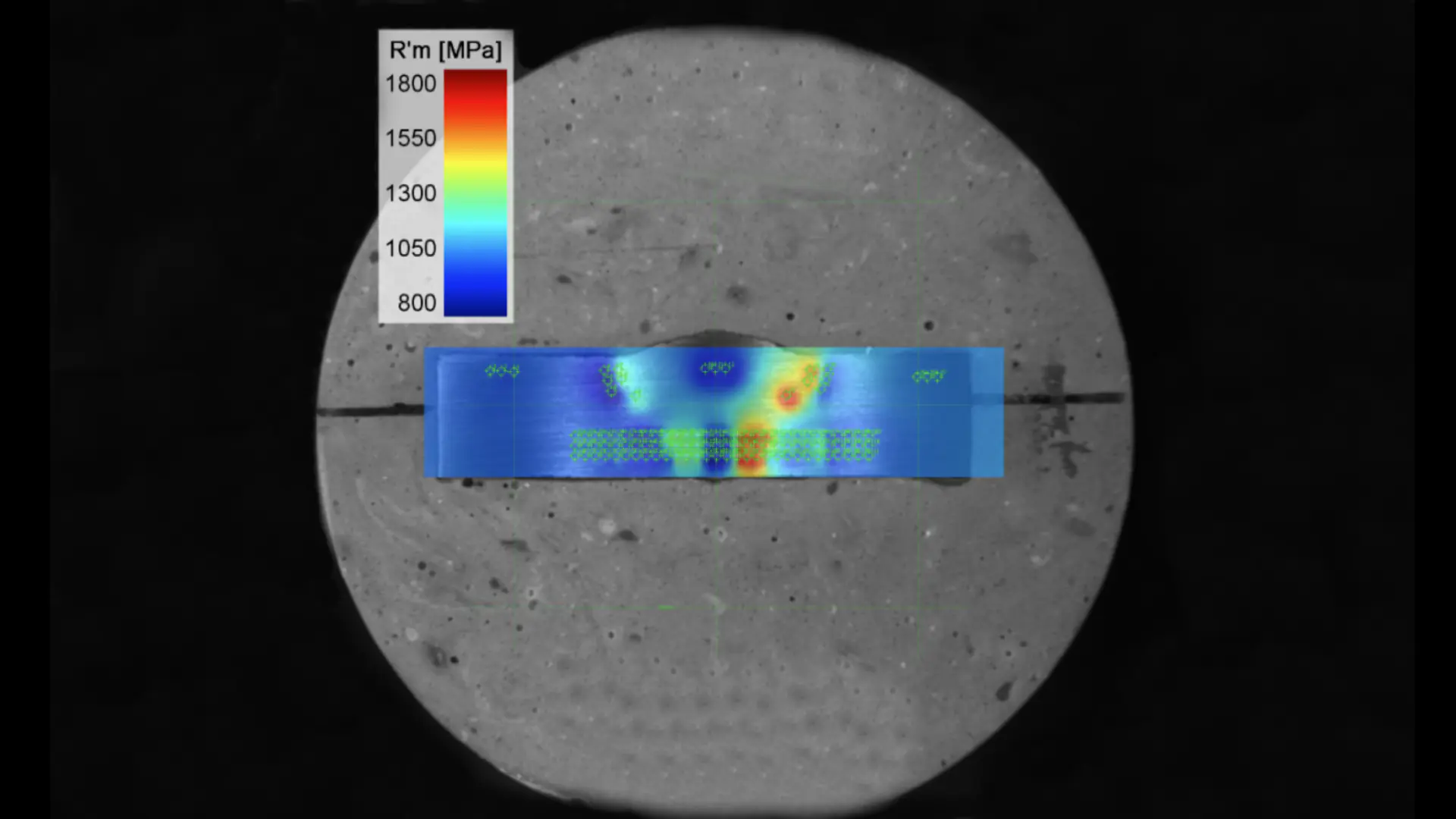

Local flow curves for precise optimization

View applications →

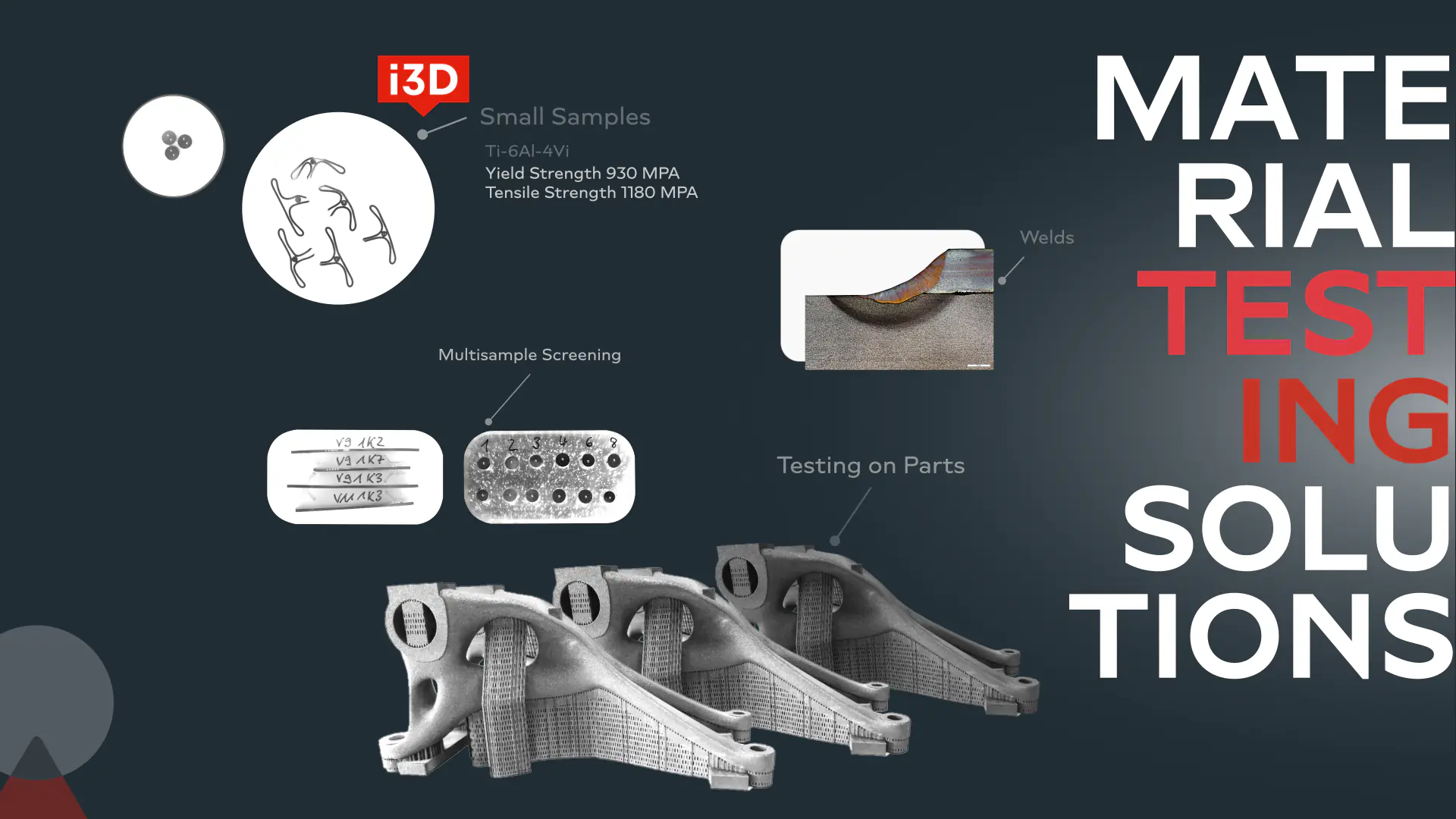

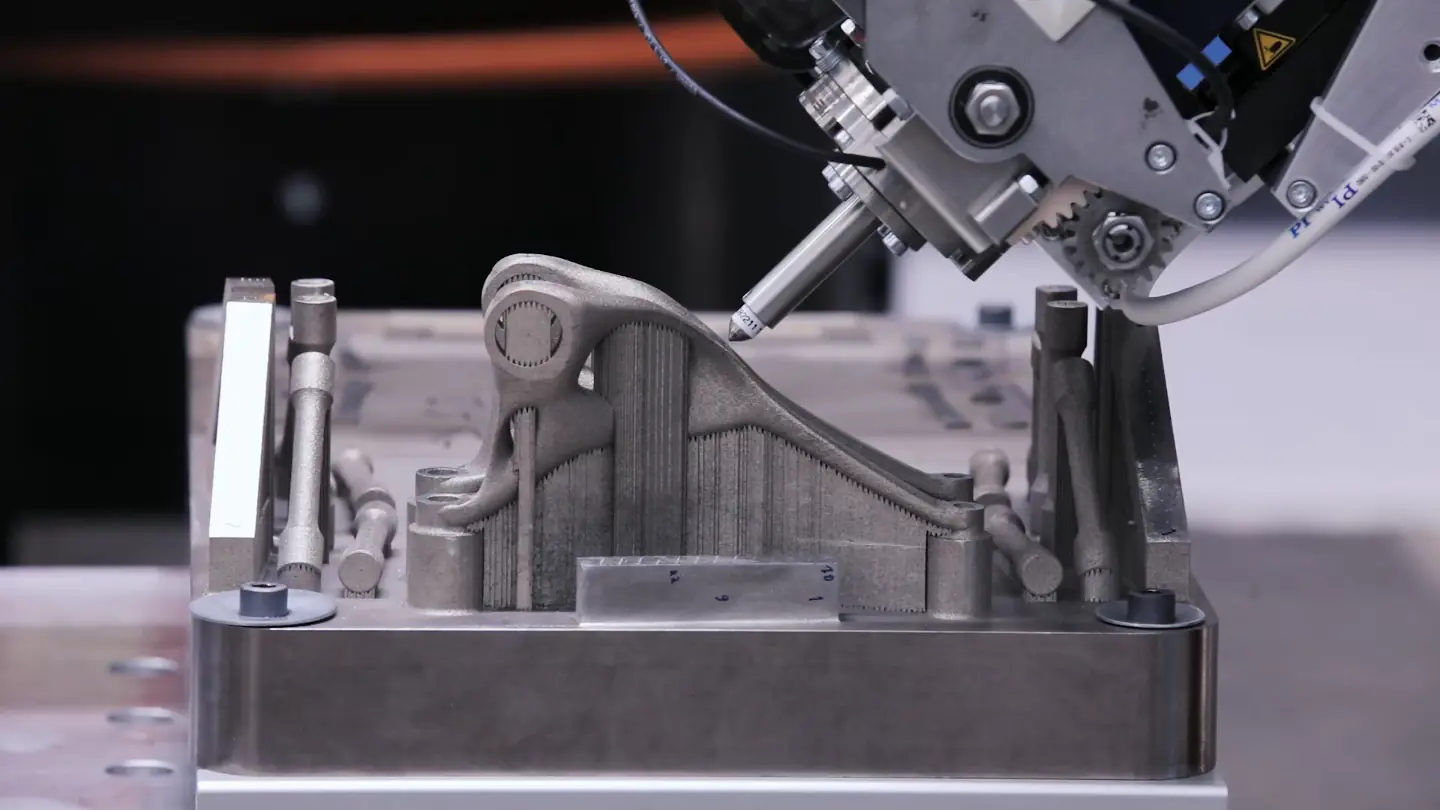

i3D® testing enables mechanical materials analysis directly on components and samples—fast, spatially resolved, and low-damage. It is used in research, quality assurance, and series production.

Plastic properties: yield strength and tensile strength

Fastest testing: 1 measurement point in 72 seconds

Fully automated measurement of 200+ points possible

Standard-compliant per DIN & ASTM (coming soon), currently DIN SPEC 4864

Local flow curves for precise optimization

View applications →

Inline testing for faster decisions

View applications →

Test and compare many samples, spatially resolved.

R&D application →

Local flow curves for realistic simulation.

R&D application →

Local mechanical properties on weld seams.

R&D application →

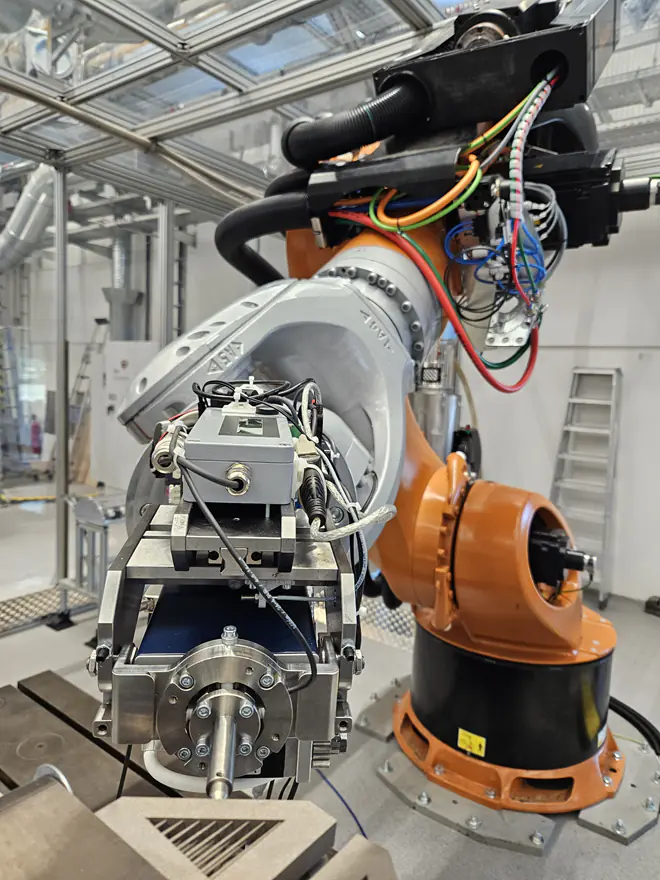

Robot-assisted testing directly in the line.

QA application →

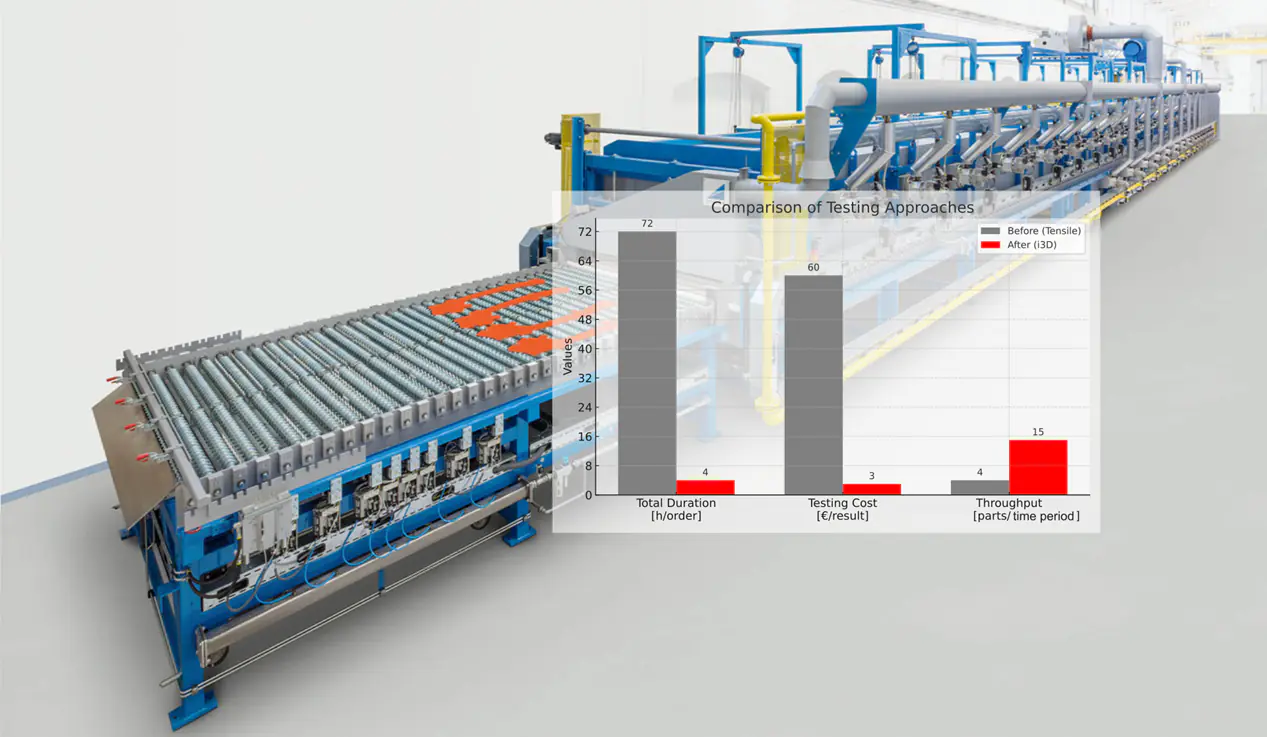

More throughput, less time and cost.

QA application →

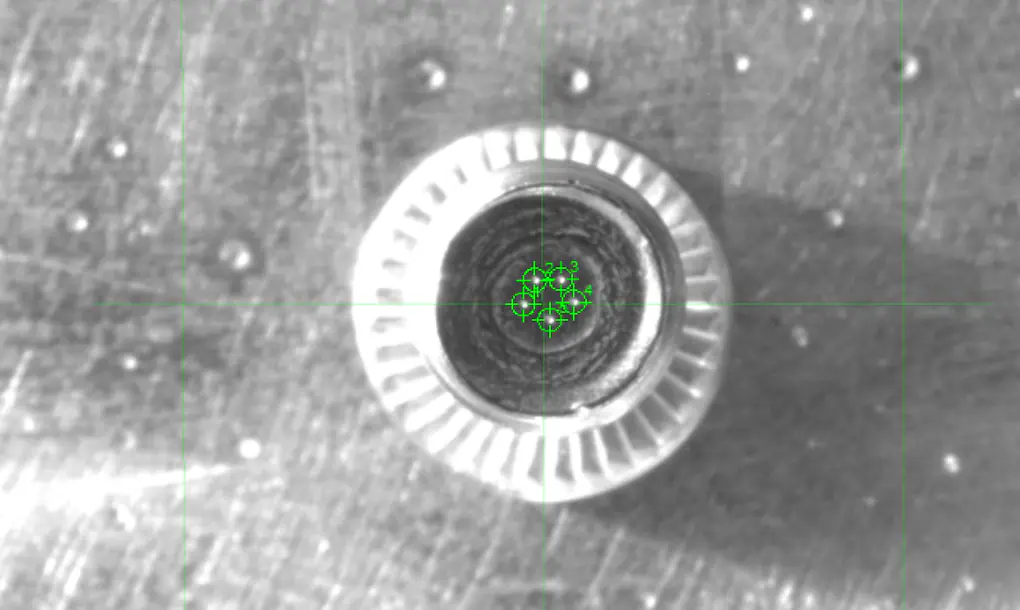

Test fasteners directly.

QA application →i3D® testing provides a cost-effective alternative to conventional tensile testing—ideal as a fast, internal QA measure.

Elaborate specimen preparation, high machine costs, time-consuming procedures.

Testing directly on the component, no machining, faster workflows, lower unit costs.

Ideal for in-process testing, supplier evaluations, and internal approvals.