Overview

i3D® Application: Material Data for FEM Simulation

In conventional FEM simulations, material behavior is usually described by uniform stress-strain curves – typically obtained from tensile tests. These global data are applied to the entire component, regardless of local material variations.

Why Global Material Models Are Often Insufficient

This approach ignores real material differences, such as varying wall thicknesses, thermal influences, forming zones, or microstructural gradients. The result: inaccurate simulations of stress distributions and failure risks.

The i3D® method enables the determination of spatially resolved plastic flow curves directly on the component – through a combination of 3D indentation measurement and FEM-based inverse calculation.

These local flow curves (including yield strength RIp0.2 and ultimate tensile strength RIm) can be used as input data for simulations with pinpoint accuracy – creating realistic material models.

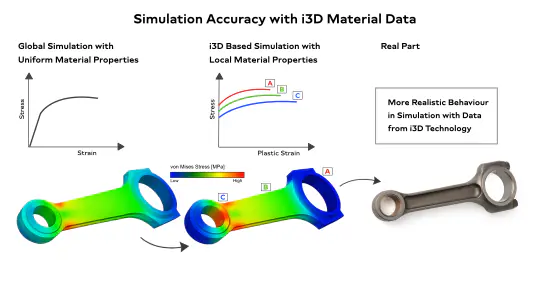

Practical Example: FEM Simulation of a Connecting Rod

A connecting rod was analyzed with two simulation approaches: Global Model: Uniform stress-strain curve across the entire component, i3D® Model: Locally measured flow curves from three zones (A = pin area, B = shaft, C = bearing).

The i3D® model clearly shows differentiated strengths: low values in zone C, medium in B, and high in A – consistent with the local loads. The result: more realistic stress distribution, improved failure prediction, and more precise virtual design decisions.

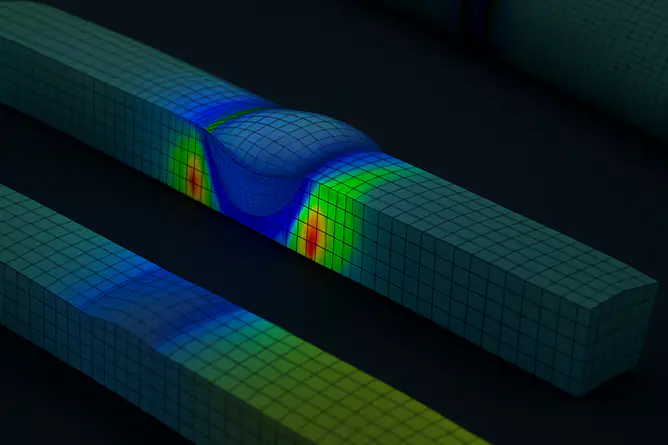

Further Insight: FEM Simulation with Flow Curves from Weld Seam & Heat-Affected Zone (HAZ)

Especially in weld seams and heat-affected zones, local mechanical properties are crucial. With i3D®, yield strength, hardening, and ductility can be spatially integrated into the simulation – e.g., for analyzing structural parts, crash zones, or crack risks.

Learn more

Further Applications

"Material Testing Solutions"