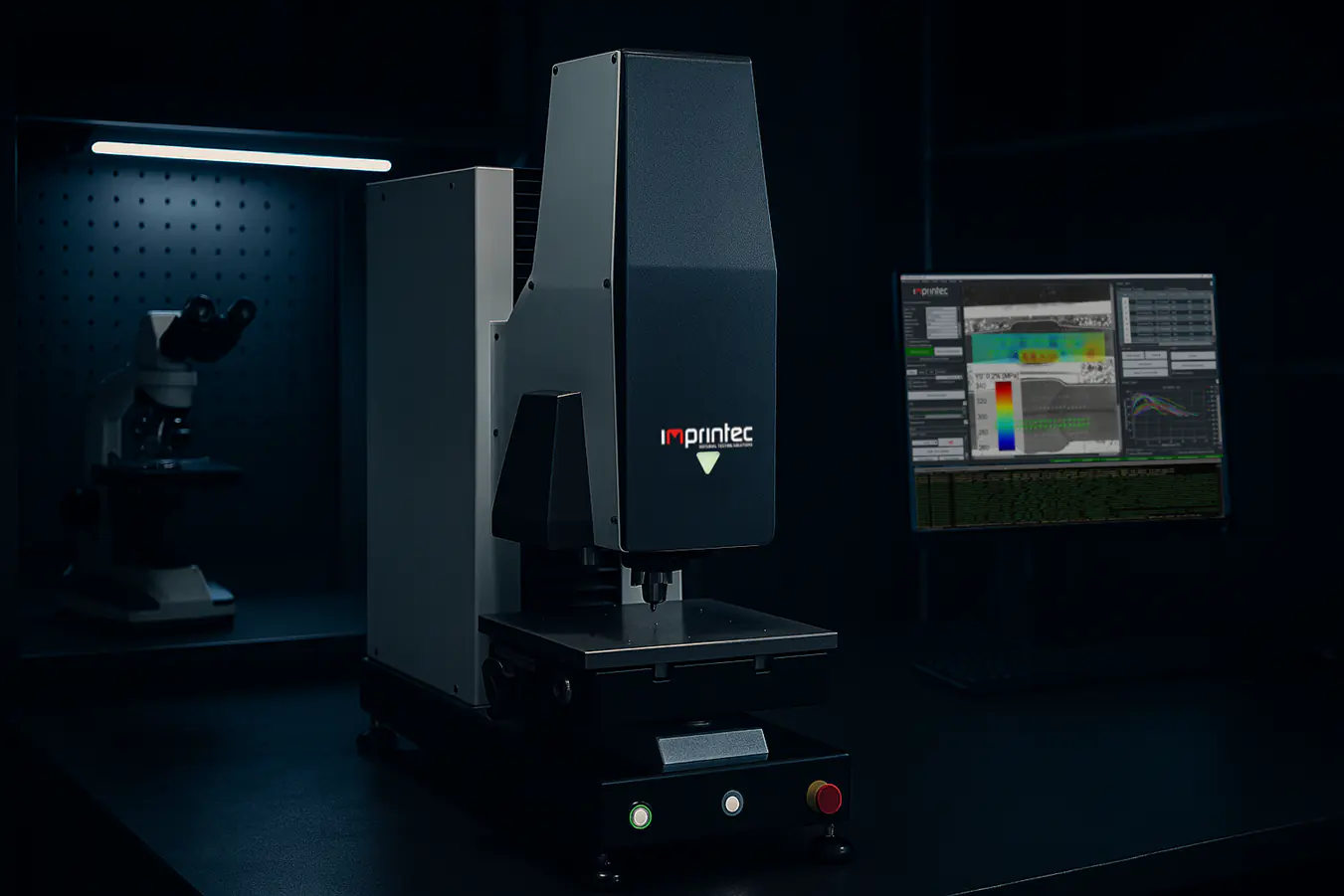

Fully automated indentation testing per DIN SPEC 4864 to derive yield and tensile strength. Optional optical 3D surface measurement via white-light interferometry.

View system →Obtain the plastic stress–strain curve without a tensile specimen: with i3D® you determine yield strength (RIp0,2) and tensile strength (RIm)—fast, local, and automated.

Request a demo

Fully automated indentation testing per DIN SPEC 4864 to derive yield and tensile strength. Optional optical 3D surface measurement via white-light interferometry.

View system →System for fully automated indentation testing per DIN SPEC 4864. Optional 3D surface measurements with white-light interferometry.

DIN SPEC 4864 indentation system incl. overview camera and XY stage. Optional optical 3D measurements via white-light interferometer.

16 weeks

New units

Demo units

Pre-owned units

Purchase (one-time) or leasing

| Product | Test function | Key features |

|---|---|---|

| i3D® WLI Pro | Indentation testing (fully automated) | Automated workflows incl. overview camera & XY stage; optional 3D surface metrology (white-light interferometry) |

| i3D® WLI Eco | Indentation testing (semi-automated) | Compact solution with optional 3D measurement |

| i3D® mBV | Indentation testing + hardness testing | Hardness per Vickers, Brinell, Rockwell (0.2–62.5 kgf); fully automated; optional optical 3D measurement |

| i3D® BVR | Indentation testing + hardness testing | Hardness per Vickers, Brinell, Rockwell (0.2–250 kgf); fully automated; optional optical 3D measurement |

Semi-automated entry system for indentation testing. Expandable with 3D metrology. Compact—ideal for lab environments.

View system →

Combination of indentation testing and integrated hardness testing (Vickers, Brinell, Rockwell). Optional 3D surface measurement.

View system →

High-load system up to 250 kgf. Ideal for demanding analyses and series testing. Includes hardness testing & optional 3D metrology.

View system →

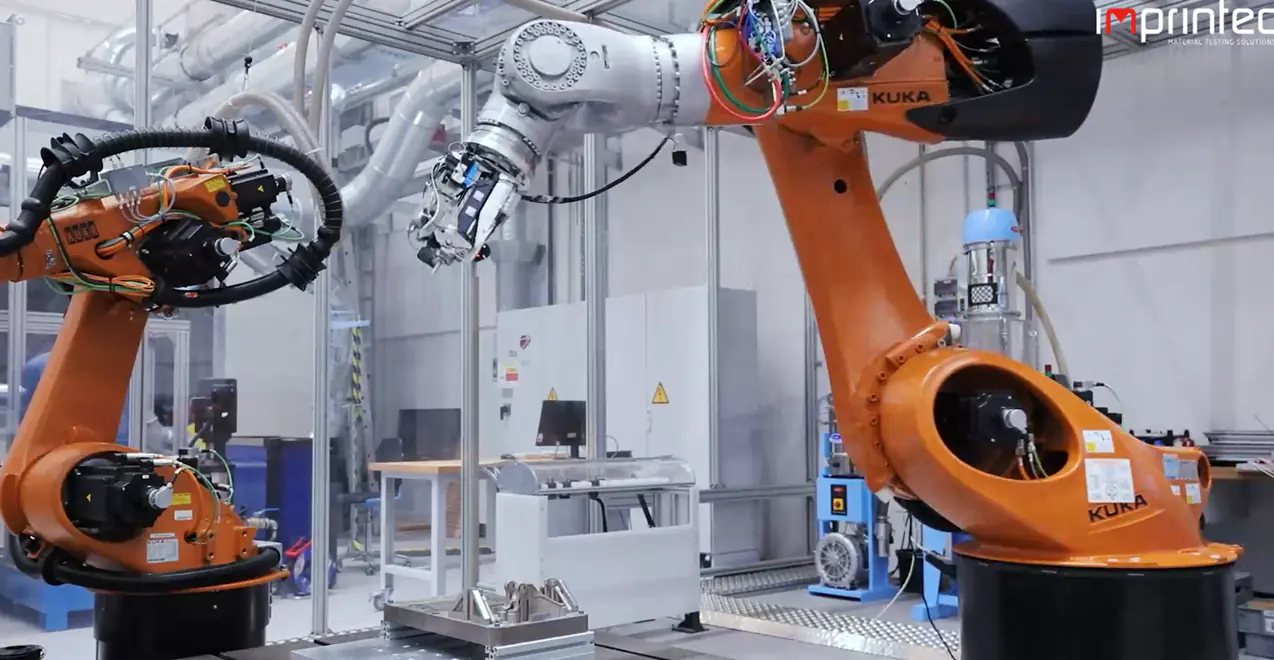

Obtain strength values fully automatically—right in production.

Coming 2026 →Semi-automated system for indentation testing per DIN SPEC 4864. Optional 3D surface measurement with white-light interferometry.

DIN SPEC 4864 indentation system. Optional optical 3D measurements with a white-light interferometer.

9 weeks

New units

Purchase (one-time) or leasing

Fully automated indentation testing per DIN SPEC 4864 plus hardness testing per Vickers, Brinell, and Rockwell. Optional: 3D surface measurement.

Fully automated system for DIN SPEC 4864 indentation testing with optional 3D metrology and integrated hardness testing (Vickers, Brinell, Rockwell). Hardness loads 0.05–62.5 kgf.

18 weeks

New units

Purchase (one-time) or leasing

Fully automated indentation testing per DIN SPEC 4864 plus hardness testing per Vickers, Brinell, and Rockwell. Optional: 3D surface measurement.

Fully automated system for DIN SPEC 4864 indentation testing with optional 3D metrology and integrated hardness testing (Vickers, Brinell, Rockwell). Hardness loads 0.05–250 kgf.

18 weeks

New units

Purchase (one-time) or leasing