Frank Palm

Materials Expert

Airbus

Research and development of materials in the aerospace sector.

Automated high-throughput testing for rapid analysis of mechanical properties – ideal for parameter studies and the development of new alloys.

“The Imprint Test i3D® offers many new possibilities for fast (high-throughput) development as well as applications in quality assurance. The approach shown here for additively (LPBF) manufactured parts and materials is just one example of successful use cases.” – Frank Palm, AIRBUS, 2023

Frank Palm

Materials Expert

Airbus

Research and development of materials in the aerospace sector.

Peter Zok

Applications – Materials Testing

Imprintec GmbH

15 years of experience in materials testing.

View profile →

Table of Contents

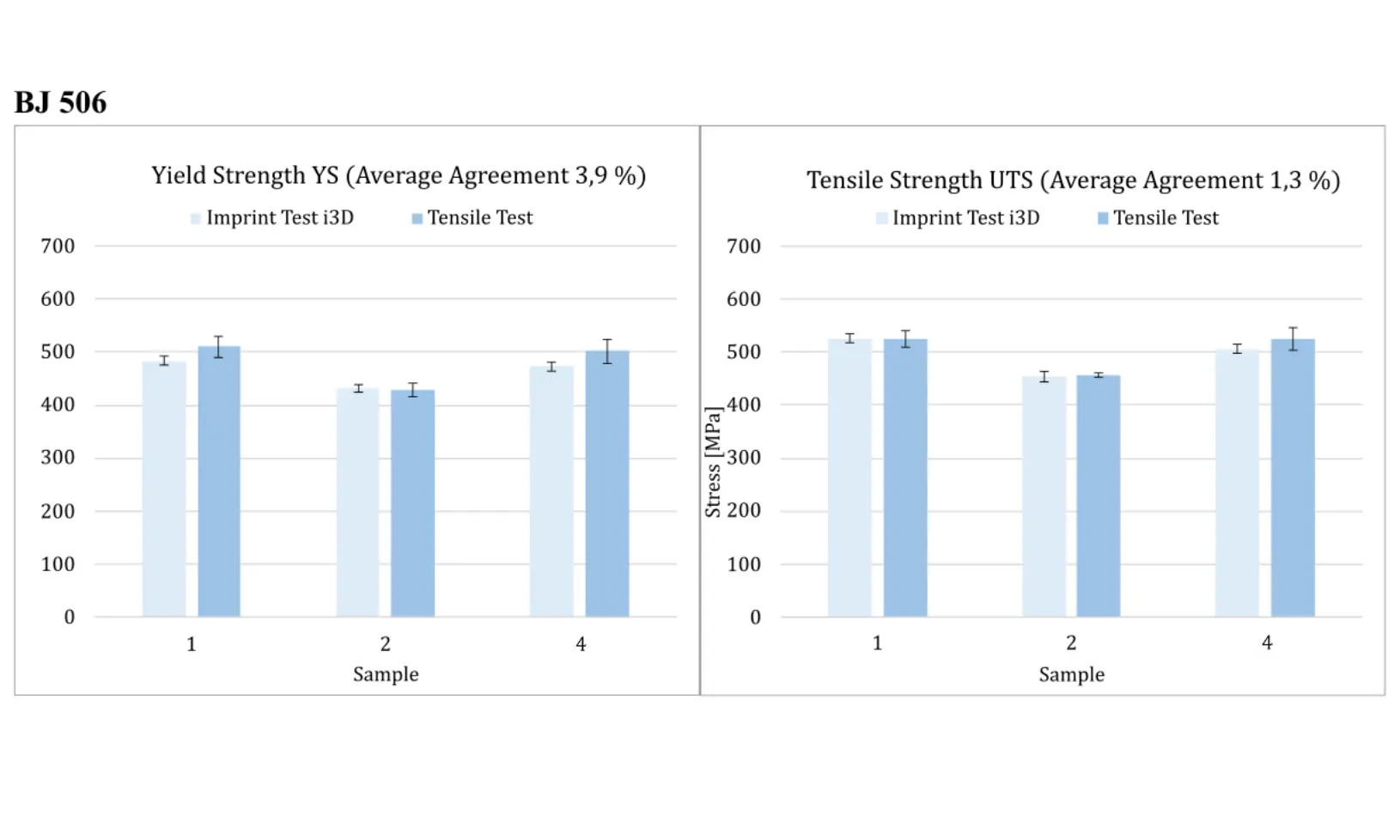

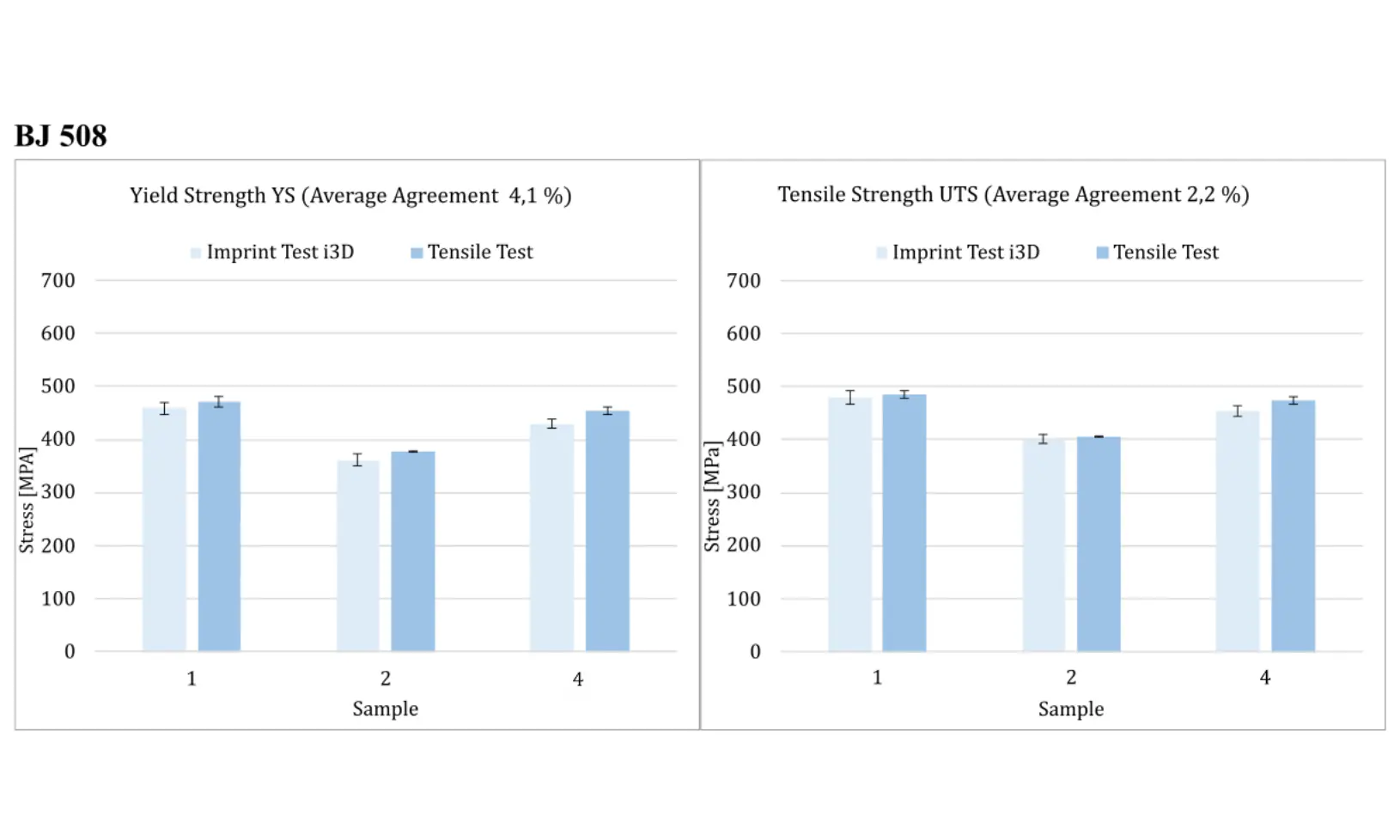

Multisample screening or high-throughput testing with the Imprint Test supports alloy development by quickly determining material data, especially in the field of additive manufacturing. In this study, 12 samples with a total of 62 plastic stress–strain curves were automatically characterized within one hour. The samples (two Scalmalloy® [AlMgScZrMn] variants) were printed as cubes and the measuring surface was ground with 800 grit. Furthermore, for the same print job, the material properties determined from the Imprint Test were compared with corresponding tensile tests. For these measurements, the Imprint Test achieves a cost reduction of 70–90% compared to tensile testing.

Additive manufacturing processes like laser powder bed fusion (LPBF) are of growing interest for lightweight part production, driven by the need for sustainable and environmentally conscious product development. The LPBF process involves layer-wise material addition, melting, and rapid solidification, enabling new material concepts—especially for aluminum alloys. Sc-modified AlMg alloys (“Scalmalloy®”) are a strong example of a material produced using this direct manufacturing route.

However, inherent challenges for 3D-printed materials arise from the complex interaction of the solidification microstructure with the final mechanical properties, which are strongly affected by post-LPBF heat treatments. Tailoring the microstructure (to minimize residual stresses, optimize strength and ductility via precipitation hardening) is difficult due to LPBF process dynamics causing irregularities and imperfections (from highly dynamic melting, solidification rates, and boundary conditions). Aluminum alloys are susceptible to defects such as solidification porosities (gas and shrinkage) and fusion defects (bonding) due to oxide contamination and other microstructural inhomogeneities.

LPBF is a complex multi-parameter process that requires fast and reliable high-throughput testing to find the “sweet spot” for manufacturing high-performance parts and to ensure part integrity. Standardized evaluation of strength and ductility for QA is time-consuming and expensive. Traditional hardness tests like Brinell or Vickers are useful for global strength but do not reliably capture plasticity. Many tensile tests also show that elongation at fracture and necking are highly sensitive to LPBF build defects (e.g., 99.5% density) and (in)correct heat treatments. Here, a technical extension of an established indentation test like Brinell—with a force-controlled procedure, 3D image analysis, and a hybrid-AI algorithm (Imprint Test)—unlocks quick and accurate assessment of material properties (strength and ductility).

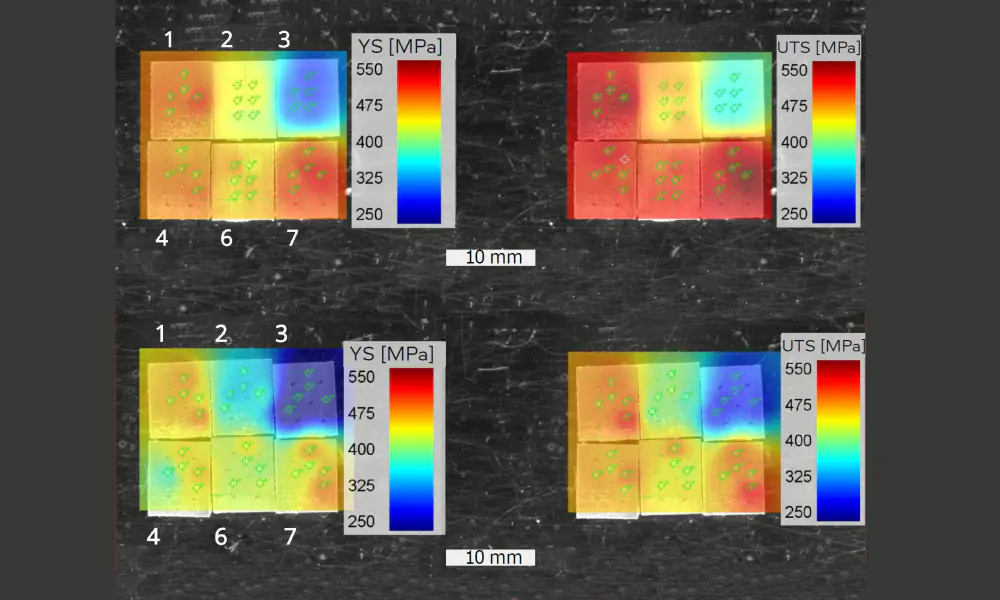

A study was conducted with two LPBF-generated Scalmalloy® (AlMgScZrMn) variants tested in different post-LPBF temper conditions. The high Sc content remains almost completely in solid solution after 3D printing, enabling a precipitation-hardening heat treatment tailored to Al-Sc metallurgy. Depending on temper, diffusion-driven Sc decomposition yields a remarkable strength increase from Sc-enriched nano-sized clusters (1–2 nm), culminating in an ordered ~4–6 nm fully coherent intermetallic L12 phase (Al3Sc(Zr)). At peak-aged temper, the yield strength of Scalmalloy® is more than double compared to the “as-printed” alloy while retaining good ductility. Mechanical properties from standardized tensile tests vs. the Imprint Test were compared and showed strong agreement (see Fig. 1). Slight discrepancies in elongation at fracture are explained by scatter in tensile results due to build imperfections from unstable LPBF parameters—also reflected in plastic stress–strain curves from the Imprint Test (see Fig. 2).

Further Applications

"Material Testing Solutions"