Overview

i3D® Application: High-Throughput Material Testing

Conventional tensile tests are often time-consuming and costly – especially when analyzing many samples in process development or quality assurance.

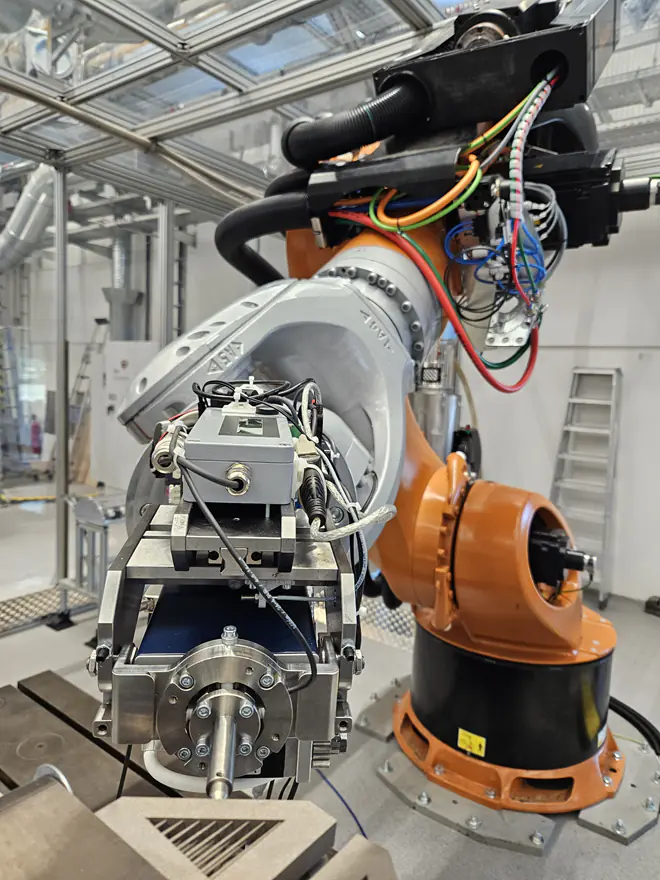

Fast, non-destructive, process-oriented

The i3D® method offers a powerful alternative: rapid, non-destructive, and process-oriented mechanical testing directly on the component – ideal for industrial environments with high testing throughput.

This enables materials to be characterized much faster, processes to be secured more effectively, and scrap rates to be significantly reduced.

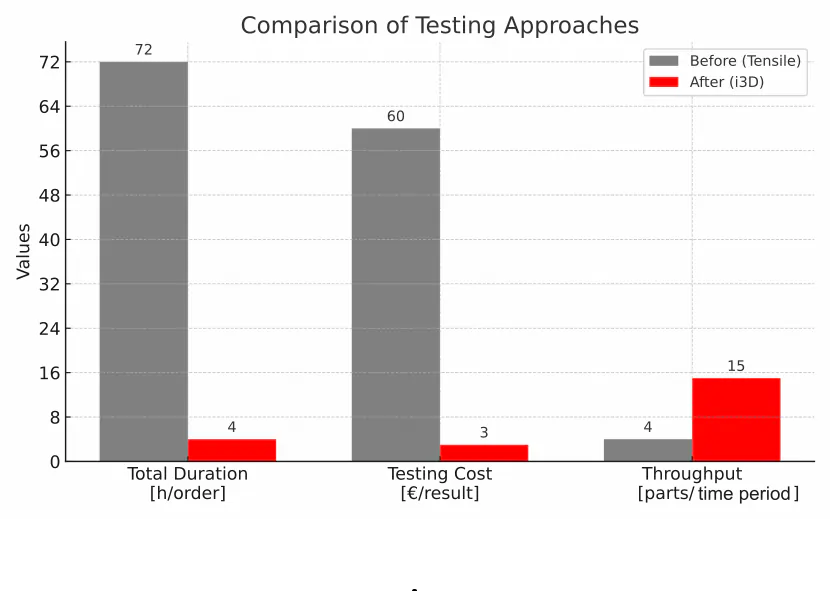

Time and Cost Savings Compared

As shown in the example, the i3D® method can reduce total testing time from 72 hours to just 4 hours – while achieving a cost reduction of more than 90% per measurement.

At the same time, testing throughput increases by a factor of four, enabling faster decision-making and more efficient process optimization – e.g., in the evaluation of heat treatment conditions or iteration of process parameters.

Typical Use Cases for i3D® High-Throughput Testing: Production, QA & Development

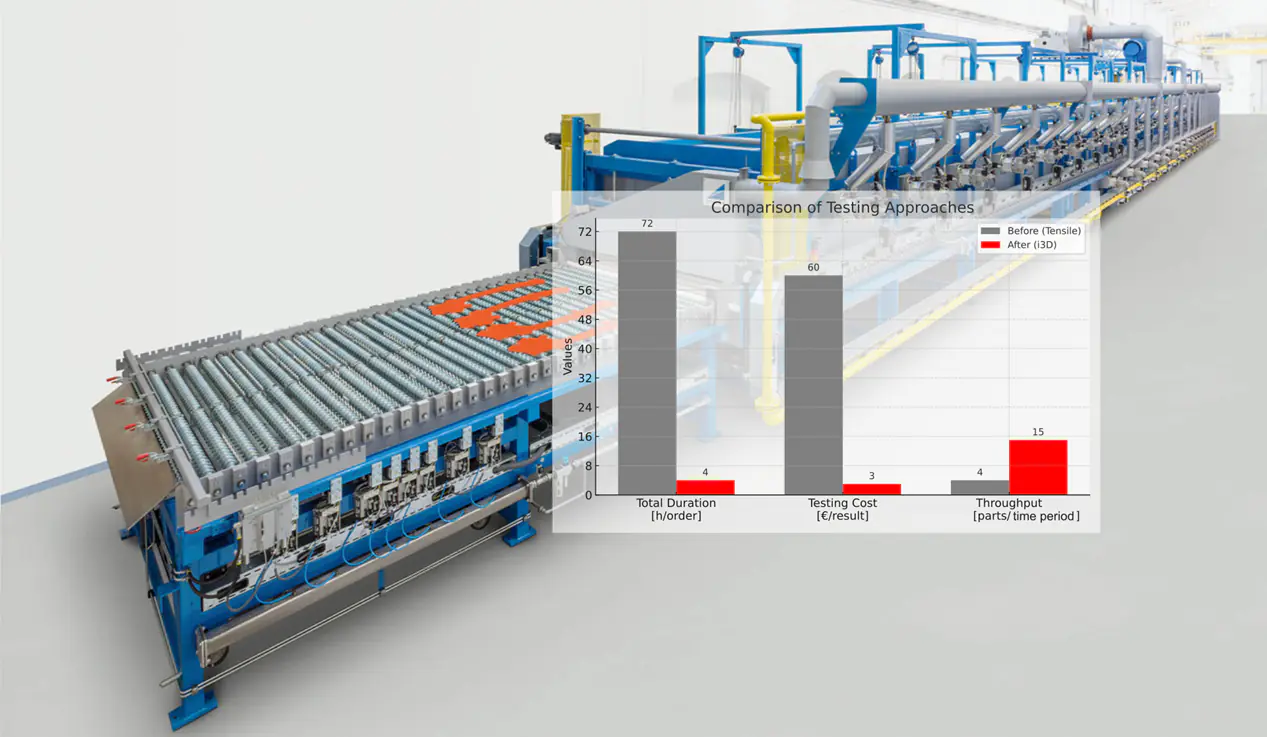

Whether in car body sheet production, validation of heat-treated components, or in the laboratory – the i3D® technology is highly flexible and delivers reliable material properties in the shortest possible time.

Learn more

Further Applications

"Material Testing Solutions"