Saskia Siegert

Head of Materials Testing Lab

Imprintec GmbH

Your primary contact for materials analysis, test methods and project coordination.

Email →

Materials Testing Lab

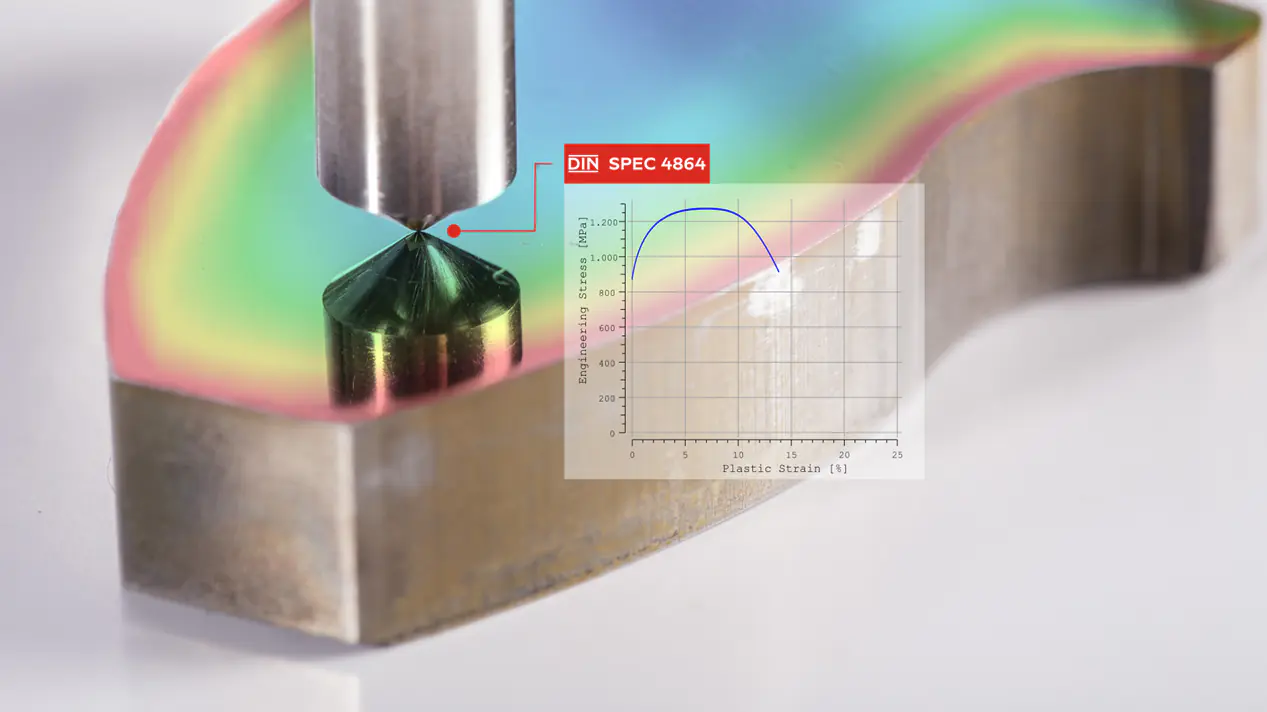

Service testing for yield strength, tensile strength, and hardness.

Request testingOur laboratory in Bochum covers the full analysis chain for metallic materials—from specimen preparation and classical hardness testing to the FEM-based i3D® indentation method. Whether for research, development or quality assurance, we deliver dependable results you can build on.

Head of Materials Testing Lab

Imprintec GmbH

Your primary contact for materials analysis, test methods and project coordination.

Email →Built on modern infrastructure, our lab scales from single-point investigations to high-throughput arrays. The table below summarizes our key services and applicable standards.

| Service | Description | Standard |

|---|---|---|

| Specimen preparation | Mechanical and metallographic preparation of your specimens | - |

| Hardness testing | Vickers, Brinell, Rockwell | DIN EN ISO 6507 / 6508 |

| Indentation testing (i3D®) | Determine the stress–strain curve directly on the component | DIN SPEC 4864 |

| Optical 3D measurement | White-light interferometry and surface topography | - |

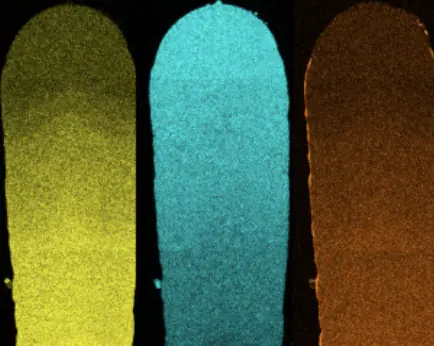

“With i3D® we validate additively manufactured parts quickly and with minimal damage.”

Explore →

“i3D® enables spatially resolved testing on the smallest additive structures.”

“We use i3D® to optimize and inspect parts efficiently.”

“i3D® accelerates our production control and saves valuable development time.”

“i3D® is essential to our research in additive manufacturing.”

“We rely on i3D® for incoming inspection of complex components.”