Adithya Kalliath

Software Development

Imprintec GmbH

Your contact for standardization, correlation measurements, and data preparation around ASTM E3499.

Get in touch →

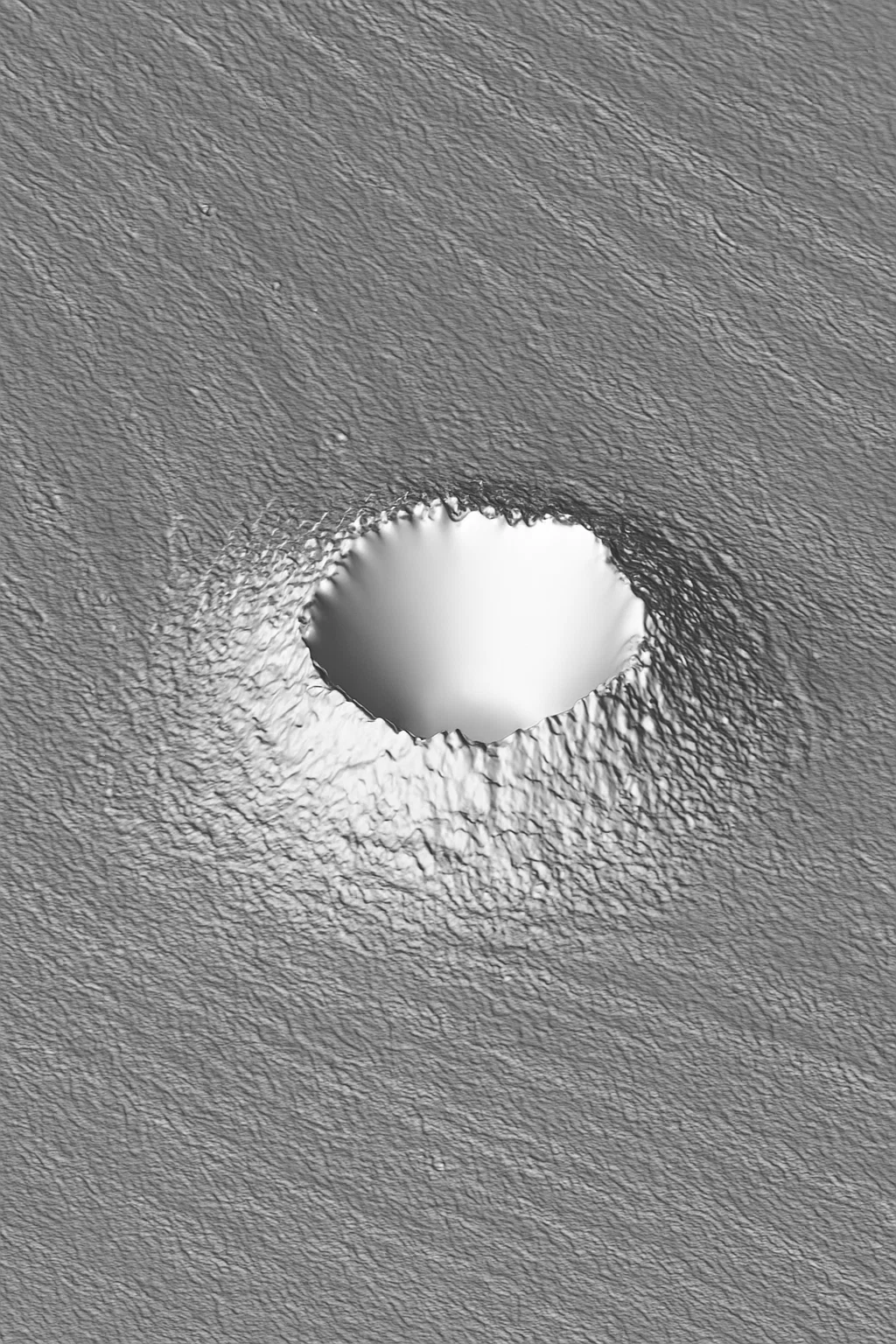

ASTM E3499-25 forms the basis for the i3D imprint test (Indentation Plastometry) to determine plastic material properties. The standard defines requirements for test setup, data acquisition, analysis, and reporting so results are reproducible and comparable.

Imprintec supports you in implementing ASTM E3499: from selecting suitable test parameters to analysis (e.g. inverse FEM) and correlation measurements between tensile tests and indentation tests.

Request consultation Read standard details| Focus | Content |

|---|---|

| Test setup | Definition of the boundary conditions for the i3D imprint test (Indentation Plastometry). |

| Data capture | Requirements for capturing force/displacement data and geometric information of the indents. |

| Analysis | Guidelines for deriving plastic properties (e.g., flow curves, YS, UTS) from the i3D imprint test. |

| Validation | Notes on reference materials, correlation measurements, and documentation. |

| Reporting | Recommended report contents to ensure traceability and comparability. |

Implementation of ASTM E3499

We support you with setup, data preparation, and correlation measurements.

Adithya Kalliath

Software Development

Imprintec GmbH

Your contact for standardization, correlation measurements, and data preparation around ASTM E3499.

Get in touch →