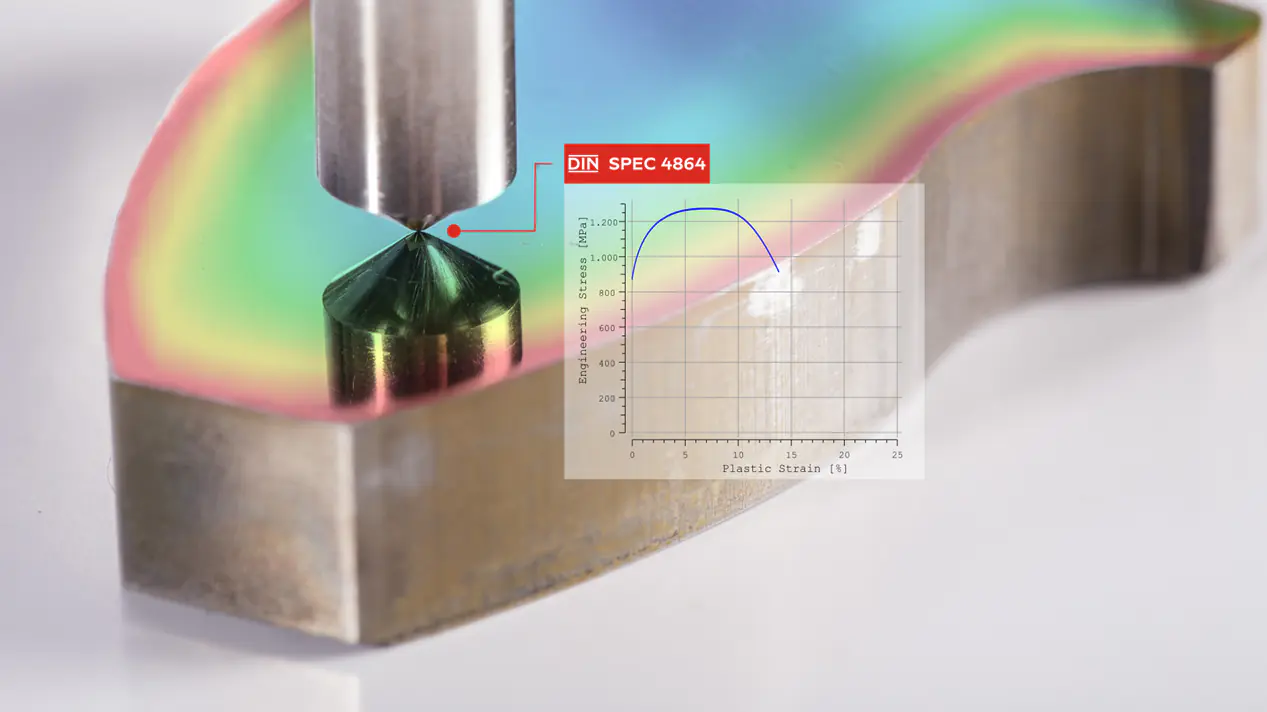

“With i3D® we validate additively manufactured parts quickly and with minimal damage.”

Explore →

Our customers share how they use i3D® in materials testing. The technology stands out for simple, fast, and local measurements that deliver tangible value. See why companies like Airbus, Tesla, Fraunhofer IWS, and Mercedes-Benz choose Imprintec.

“With i3D® we validate additively manufactured parts quickly and with minimal damage.”

Explore →

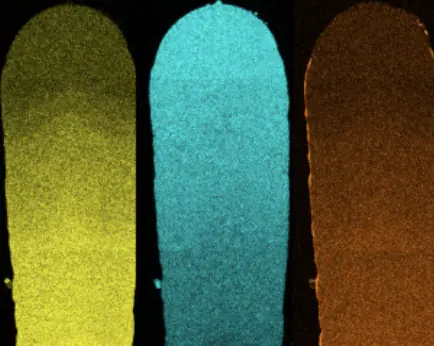

“i3D® enables spatially resolved testing on the smallest additive structures.”

“We use i3D® to optimize and inspect parts efficiently.”

“i3D® accelerates our production control and saves valuable development time.”

“i3D® is essential to our research in additive manufacturing.”

“We rely on i3D® for incoming inspection of complex components.”

These customer voices show how i3D® delivers fast, simple, and reliable mechanical properties—right where they are needed. From additive manufacturing to aircraft parts and vehicle components, i3D® stands for practical, local materials testing with new possibilities.

Discover