i3D testing technology: Yield strength RIp0.2, tensile strength RIm from indentations.

Discover →

TEST

QUALIFY

OPTIMIZE

Imprintec is shaping a new standard in metal testing: i3D® lets engineers quickly and non-destructively capture accurate stress–strain curves.

i3D® Stress-Strain Curves

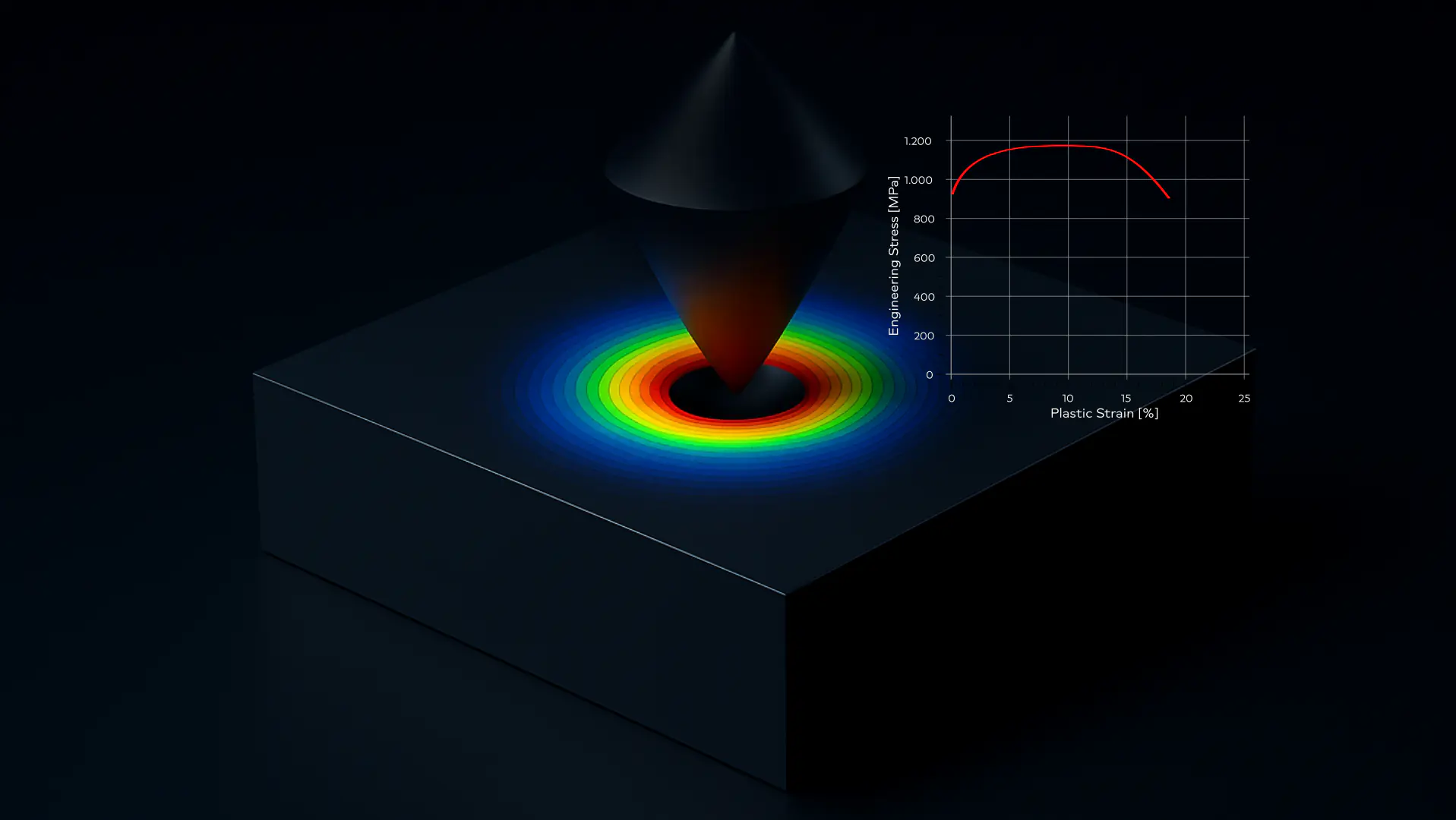

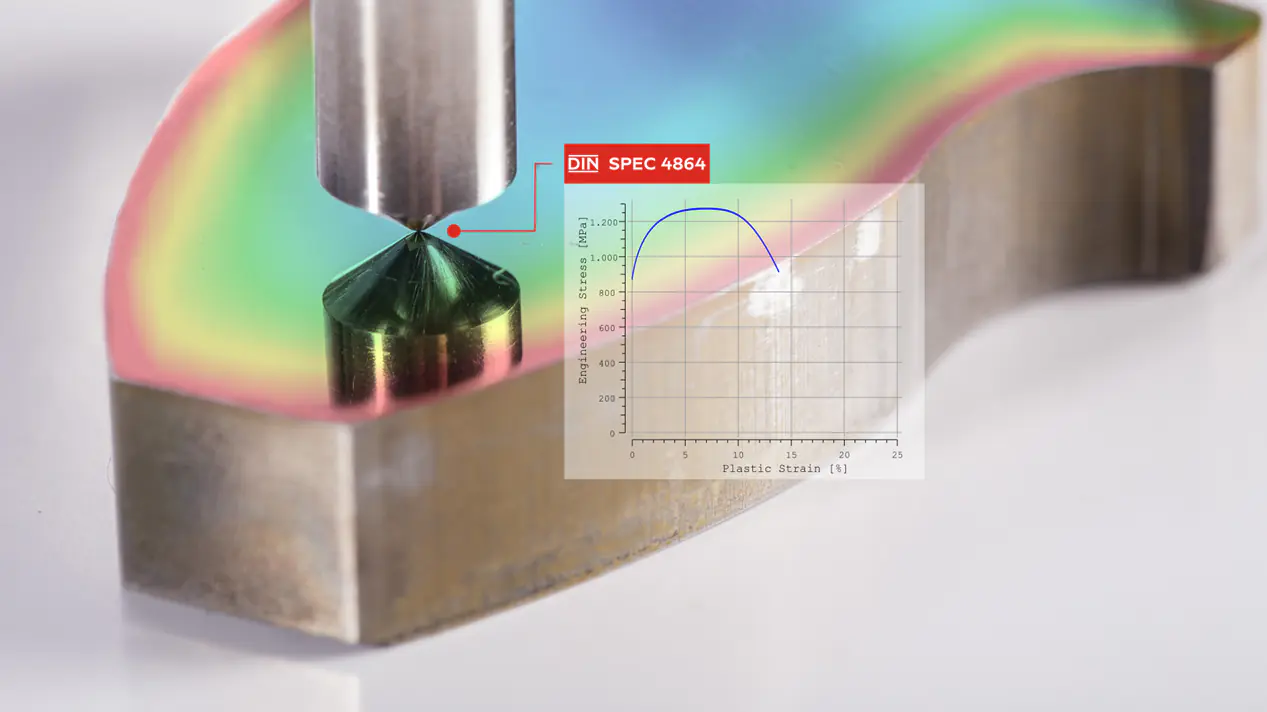

The new way of material testingPlastic stress–strain curve without a tensile specimen: With i3D® WLI you determine yield strength RIp0.2 and tensile strength RIm — fast, local, and automated.

Plastic strain vs. engineering stress with overlayed true stress/true plastic strain from a representative i3D® test.

Plastic properties: Yield strength RIp0.2, tensile strength RIm

Fastest test: 1 measuring point in 72 seconds

Fully automated measurement of over 200 measuring points possible

Coming soon: compliant with DIN & ASTM; currently DIN SPEC 4864

i3D testing technology: Yield strength RIp0.2, tensile strength RIm from indentations.

Discover →

Services: Determine yield strength RIp0.2, tensile strength RIm & hardness testing

Discover →

For research & development and quality assurance

Discover →

Reports from AIRBUS and other customers.

Discover →Welcome to Imprintec

"Stress–strain curves from indentations!"

i3D® provides research institutions with access to stress- and strain-relevant material properties directly on the component. Ideal for spatially resolved material investigations and cost-efficient parameter studies.

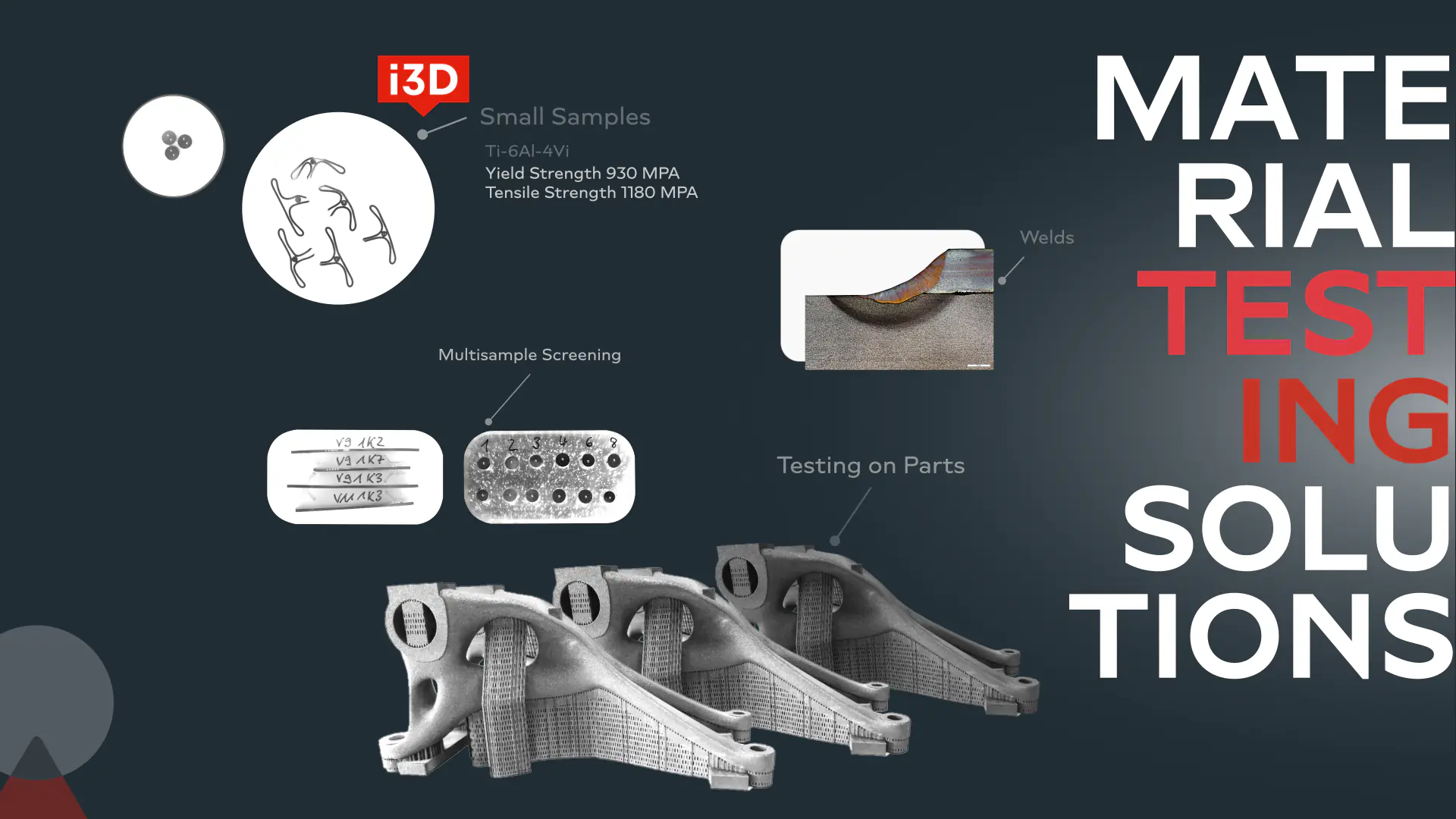

Specimen testing, parameter studies, multi-sample screening, weld seam analysis, characterization of strength profiles and work-hardened zones

Low-cost access to spatially resolved stress–strain curves — even with a single specimen. No elaborate specimen preparation or tensile tests required.

Research projects, comparative studies, material characterization, process development

The i3D® technology supports R&D in aerospace with spatially resolved mechanical testing directly on the component — ideal for optimizing safety-critical parts.

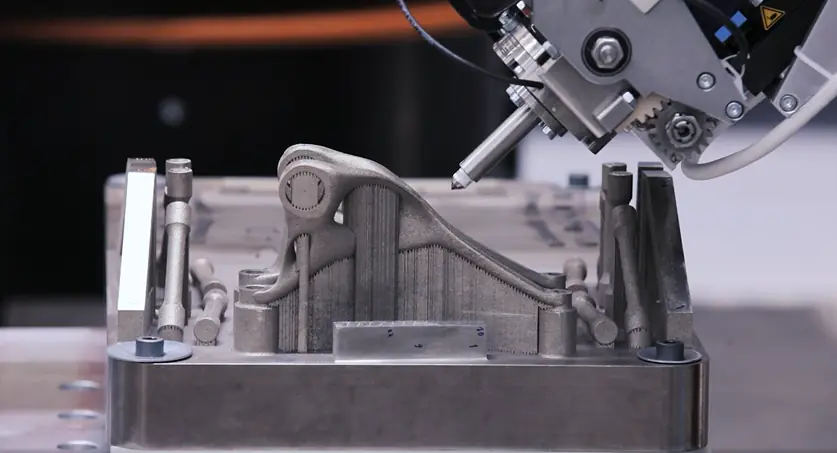

Alloy development, testing of critical components, weld seam analysis, near-surface characterization, parameter studies on additively manufactured components

Fast, spatially resolved mechanical analysis with minimal damage. Cost-effective testing for complex R&D questions.

Welds on engine components, turbine blades, structural parts, additive components

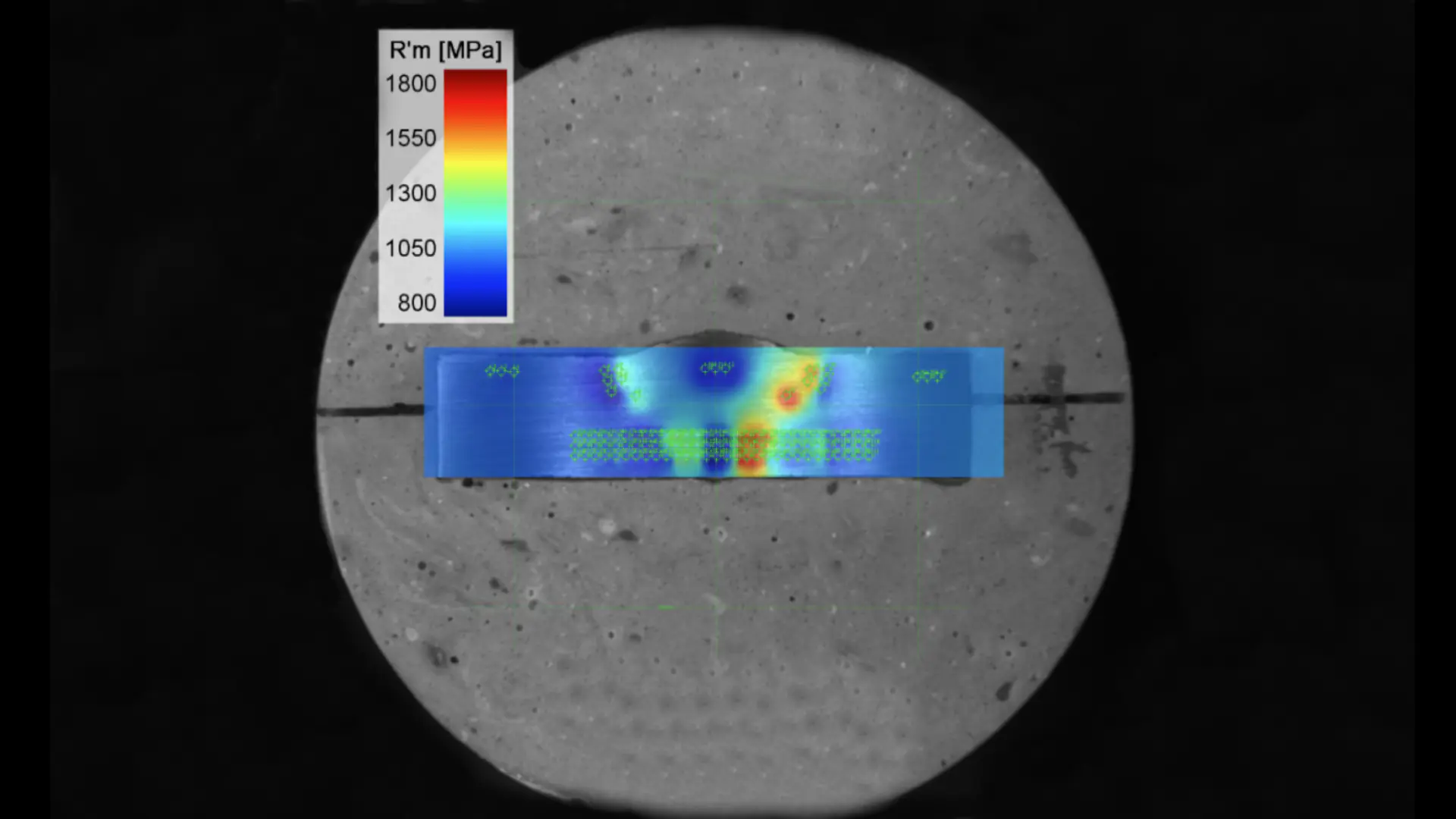

In the automotive industry, i3D® enables targeted investigation of safety-critical components such as welds or crash zones. The technology provides spatially resolved material properties — directly on the real component.

Weld seam analysis, mechanical characterization of transition & near-surface zones, data provision for FEM & crash simulations

Strength analysis without elaborate specimen preparation. Spatially resolved stress–strain data for realistic simulations.

Body structures, welds in crash zones, vehicle frames, FE model calibration

In medical technology, precise, low-damage testing of the smallest safety-relevant components is essential. i3D® enables quality assurance and material analysis of implants and functional components — directly from production.

Testing of microstructures, go/no-go analyses, supplier qualification, in-process testing, implant testing

Spatially resolved access even for miniature parts. Measurement of yield strength RIp0.2 and tensile strength RIm on delicate components — fast and with minimal damage.

Pacemakers, implants, surgical tools, micromechanics in medical devices

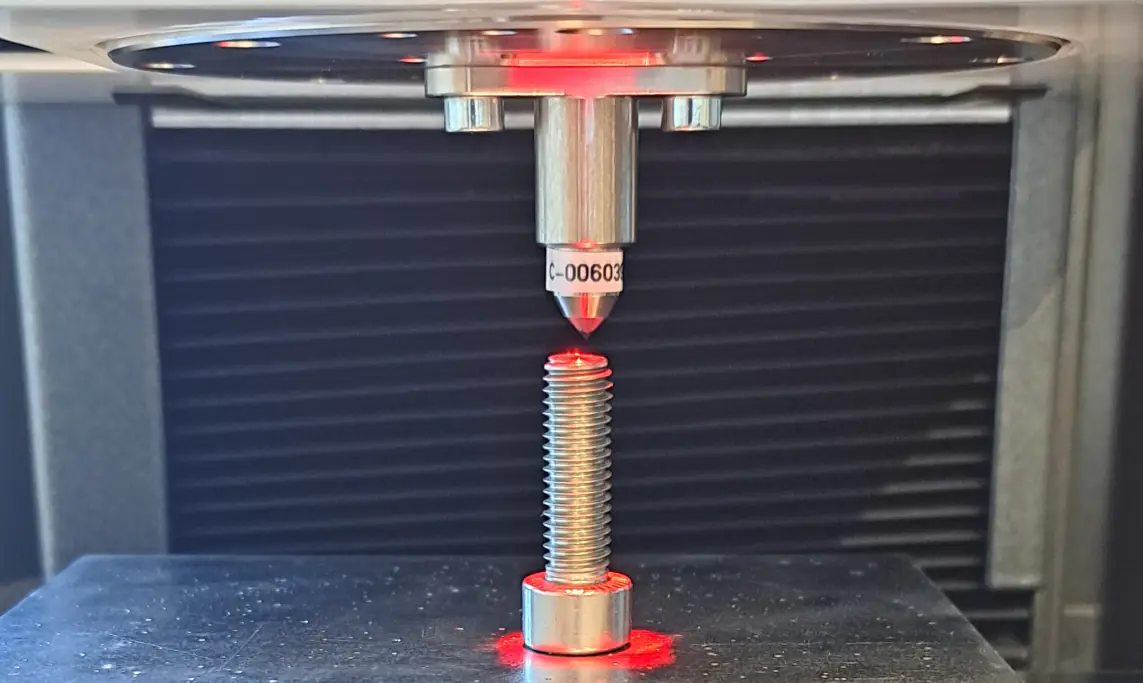

The i3D® technology enables mechanical characterization of components and fasteners in research, development, and quality assurance — especially on safety-critical structures.

Testing of fasteners, small parts, ammunition components, alloy development, parameter studies

Fast and cost-efficient test methods with direct access to mechanical properties — spatially resolved, low-damage.

–

i3D® provides precise insights into the mechanical properties of the smallest components — ideal for functional monitoring, failure analysis, and quality control in the electronics industry.

Component testing, functional checks, failure analysis, characterization of degree of deformation, go/no-go assessments, process optimization

Cost-effective, fast testing of microstructures with detailed mechanical data — ideal for in-house QA and optimization.

Connectors, contacts, fine circuit elements

According to DIN SPEC 4864, the indentation method is a low-damage test procedure for determining mechanical properties, especially of metals. A test body is pressed into the material surface with a defined force while penetration depth and material deformation are measured. Using numerical evaluation, this yields a stress–strain curve similar to a tensile test. This allows determination of values such as yield strength RIp0.2 and tensile strength RIm.

The method is particularly suitable for small samples or hard-to-access components and quickly delivers meaningful results without elaborate specimen preparation — an efficient alternative to conventional tensile testing.

Learn more about the testing technologyIn additive manufacturing, the indentation method — especially within multi-sample screening — has proven extremely useful. Users report that mechanical properties can be determined directly on the smallest specimen geometries without producing extensive tensile samples. Parameter studies become significantly more efficient: multiple printing parameters (e.g., laser power, scan strategy, cooling rates) can be examined in parallel on small test bodies. This not only saves material and time, but also enables early materials evaluation directly on the build plate.

The method is becoming an invaluable tool for process development and quality assurance.

Learn more

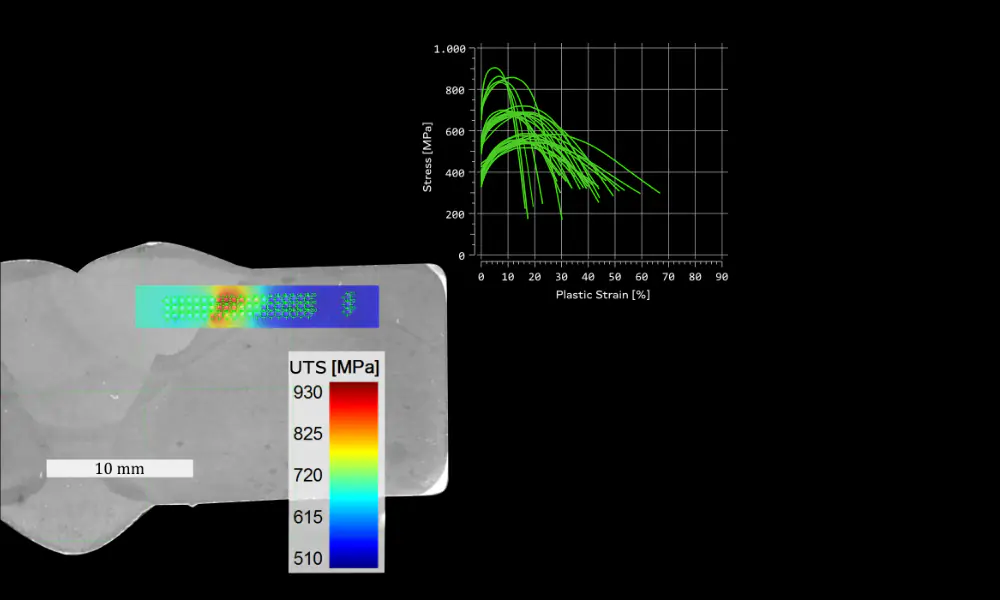

A major advantage of the indentation method is its exceptionally fast execution. In less than four minutes, up to three complete stress–strain curves can be recorded and evaluated — even with minimal sample preparation.

This speed enables efficient material comparisons, rapid parameter studies, and quick conclusions on material quality — ideal for development, process control, and serial monitoring.

Learn more about the testing technologyi3D® revolutionizes mechanical materials testing — especially where conventional methods like tensile testing reach their limits. Instead of manufacturing elaborate standard specimens, i3D® enables direct strength testing on real components — low-damage, precise, and time-saving. Thanks to fully automated multi-sample screening, over 500 stress–strain curves can be acquired in a short time — first results are often available within a minute.

A key advantage: Spatially resolved testing of mechanical properties allows targeted detection of strength gradients, e.g., in heat-affected zones, surface layers, or additively manufactured structures with intentional hardening. This makes i3D® the ideal solution for research, development, and production monitoring.

Eliminating elaborate specimen preparation, gripping fixtures, or machine changeovers significantly reduces costs without compromising significance or precision. i3D® brings new efficiency to material characterization — directly where it’s needed.

Explore applications

Testing device for fully automated indentation testing according to DIN SPEC. Optional 3D surface measurement using white-light interferometry.

Device for indentation testing per DIN SPEC 4864 incl. overview camera and XY cross table. Optional optical 3D measurements with white-light interferometer.

16 weeks

New devices

Demo units

Used devices

Purchase (one-time payment) or leasing

Testing device for semi-automated indentation testing according to DIN SPEC. Optional 3D surface measurement using white-light interferometry.

Device for indentation testing per DIN SPEC 4864 incl. Optional optical 3D measurements with white-light interferometer.

9 weeks

New devices

Purchase (one-time payment) or leasing

Testing device for fully automated indentation testing according to DIN SPEC. Also supports hardness testing to Vickers, Brinell, and Rockwell. Optional: 3D surface measurement.

Fully automated testing device for indentation testing per DIN SPEC 4864 with optional 3D measurement and integrated hardness testing (Vickers, Brinell, Rockwell). Hardness test loads: 0.05 – 62.5 kgf.

18 weeks

New devices

Purchase (one-time payment) or leasing

Testing device for fully automated indentation testing according to DIN SPEC. Also supports hardness testing to Vickers, Brinell, and Rockwell. Optional: 3D surface measurement.

Fully automated testing device for indentation testing per DIN SPEC 4864 with optional 3D measurement and integrated hardness testing (Vickers, Brinell, Rockwell). Hardness test loads: 0.05 – 250 kgf.

18 weeks

New devices

Purchase (one-time payment) or leasing