Local UTS measurement directly on the seam—without standardized specimens or part destruction.

Request now →

Overview

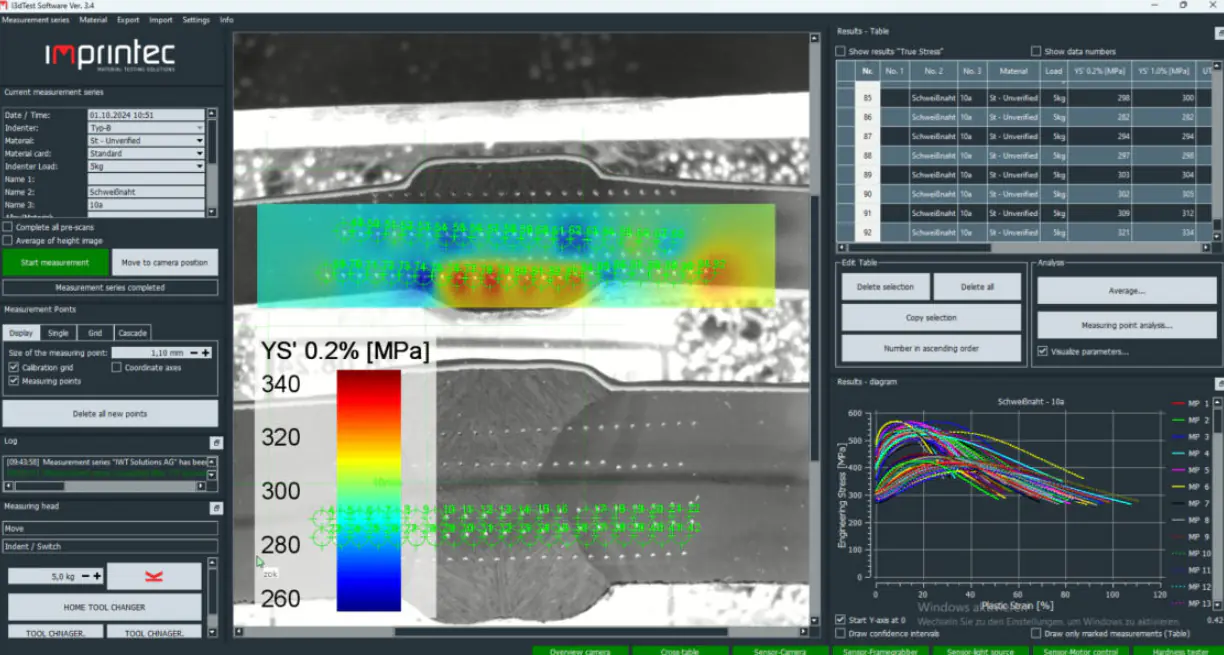

The i3D® method is based on force-controlled indentation of a diamond indenter into the material. A small, precise indentation with a minimal affected zone is created—similar to hardness testing.

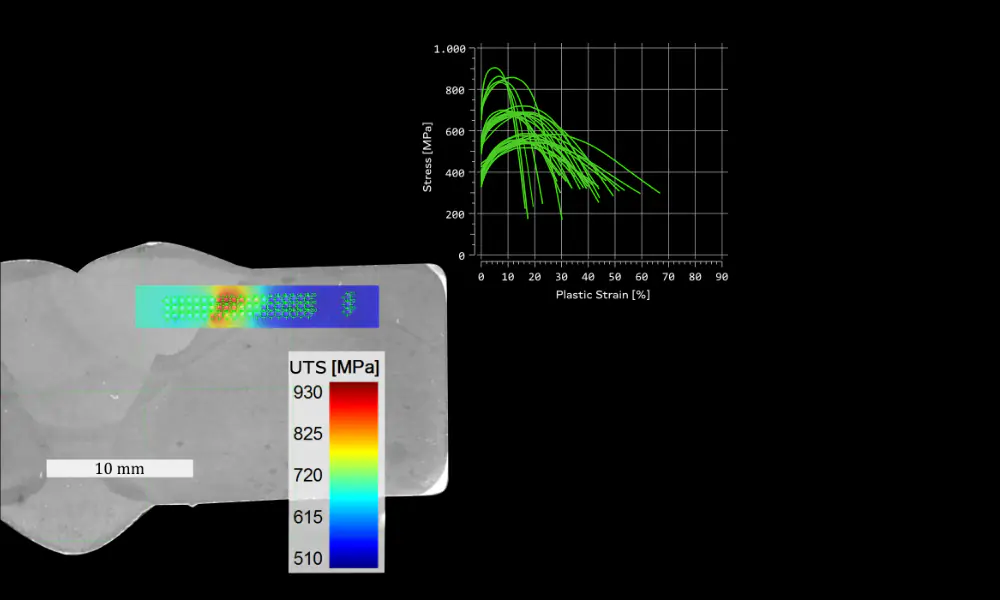

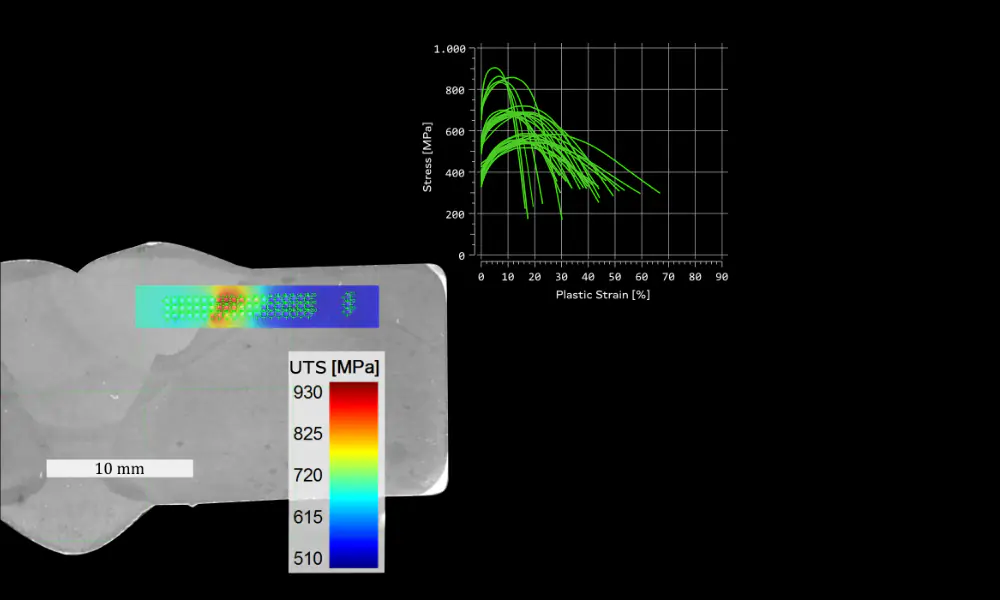

Unlike classical hardness tests, the indentation is captured in full 3D and evaluated via inverse finite element analysis. This yields full, spatially resolved stress–strain curves.

Key properties such as yield strength RIp0.2 and ultimate tensile strength RIm can be determined directly on the real component—fast, low-damage, and locally differentiated.

Access to plastic properties is no longer limited to standardized specimens: measurements can be taken directly on the weld seam, in the heat-affected zone (HAZ), or at critical structural details.

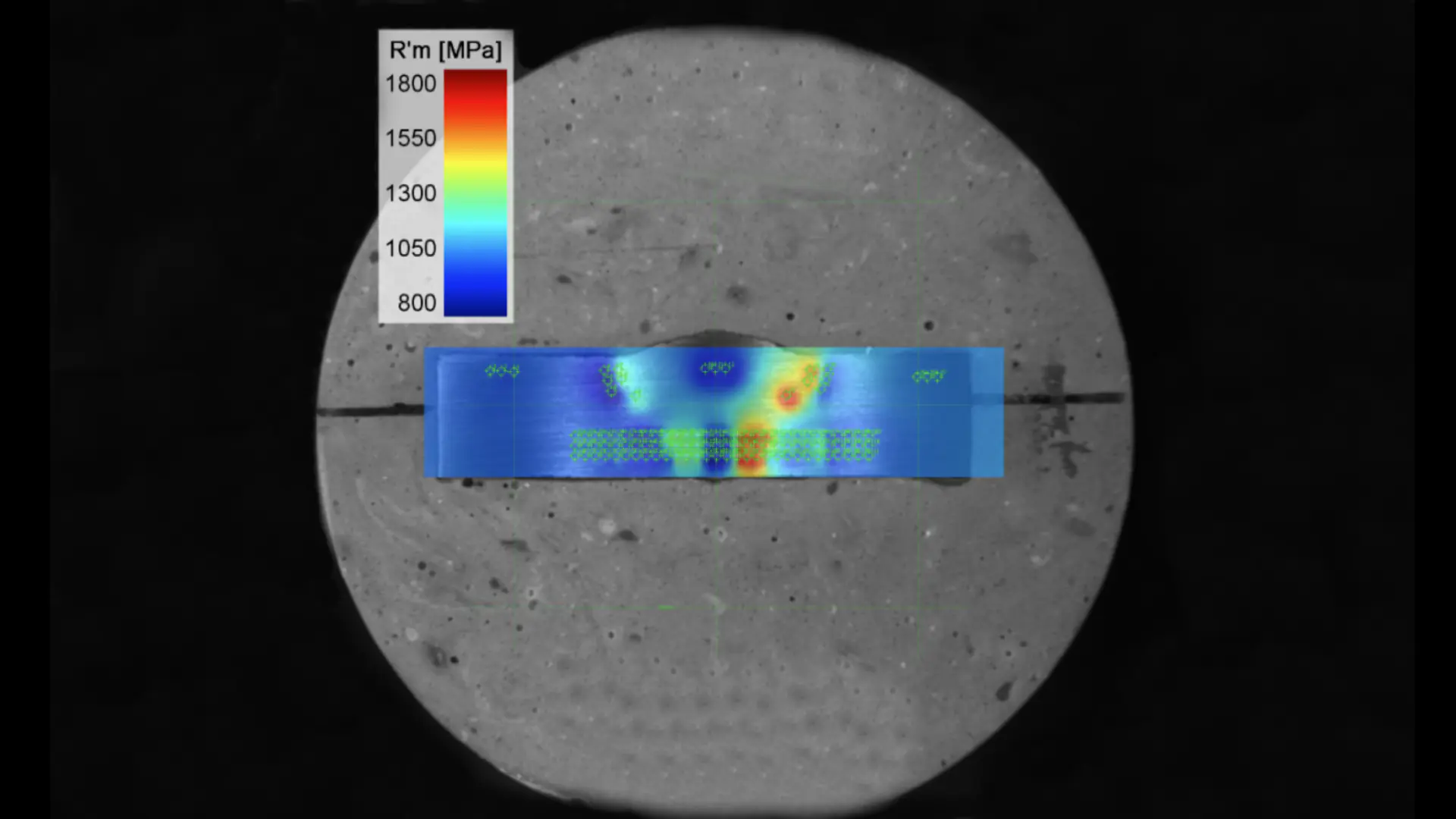

This enables true screening of welded joints—with quantifiable evaluation of strength, yield strength, and material quality in the weld region.

Typical applications include load-bearing steel structures, bridge components, crash-relevant automotive parts, and airframes—anywhere failure starts locally and therefore must be tested locally.

Local UTS measurement directly on the seam—without standardized specimens or part destruction.

Request now →

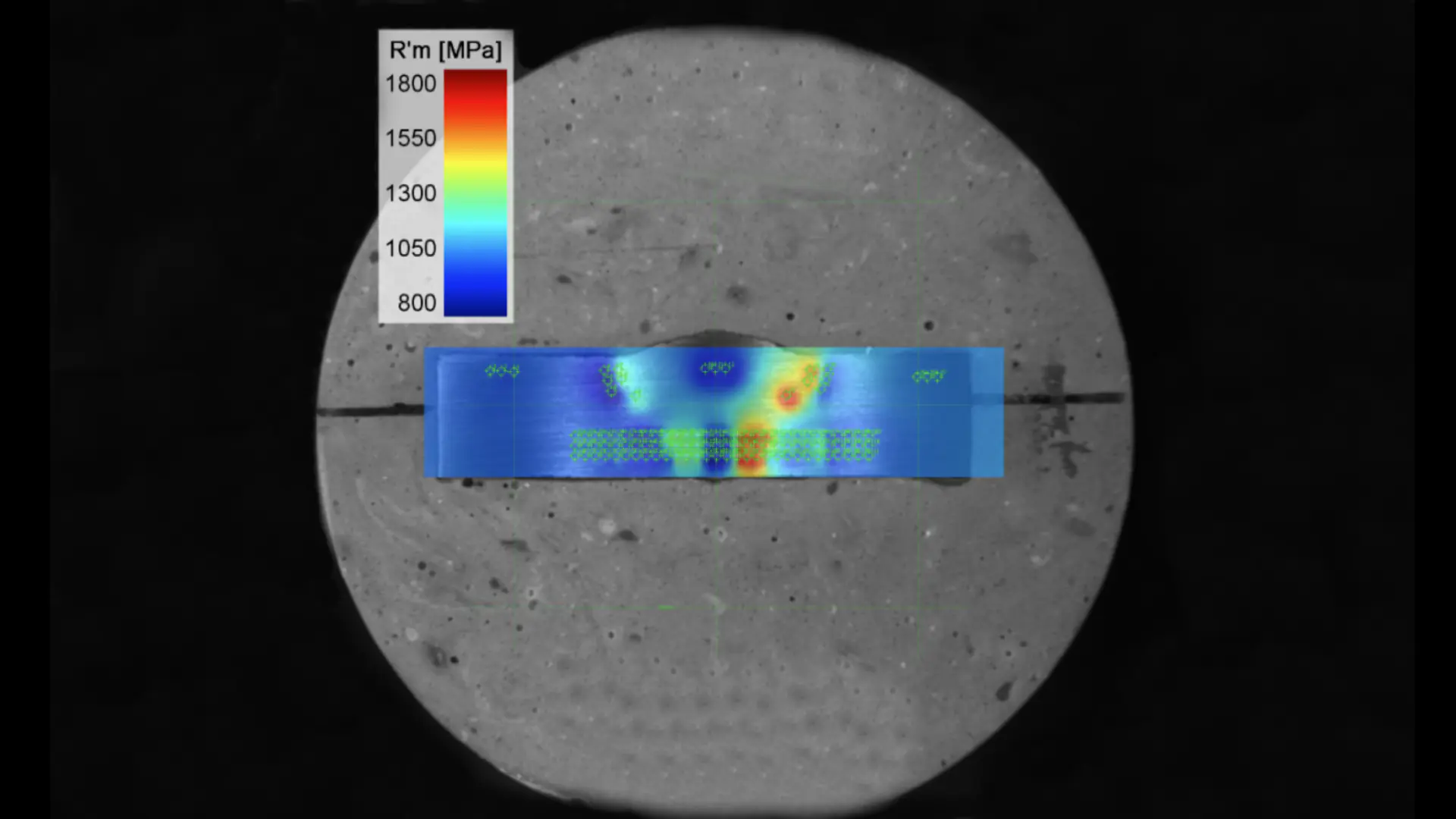

Mapping yield strength across the HAZ and along the weld seam.

Book a demo →i3D® provides high-resolution mechanical properties directly on the component—fast, precise, and without destruction. Combined with 3D surface measurement and FEM-based evaluation, it becomes a powerful tool for modern weld assessment.

Learn more

Further Applications

"Material Testing Solutions"