Local

Properties.

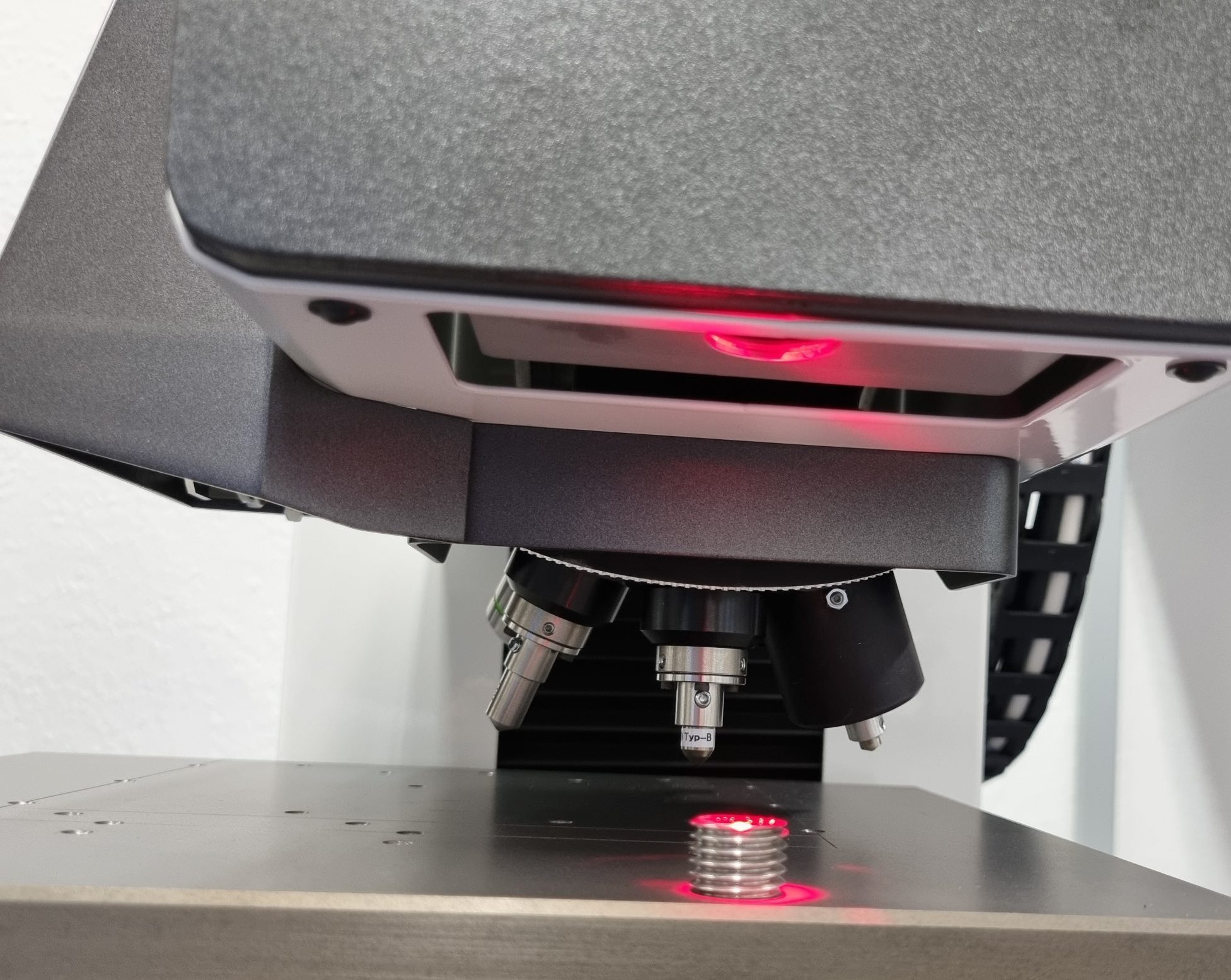

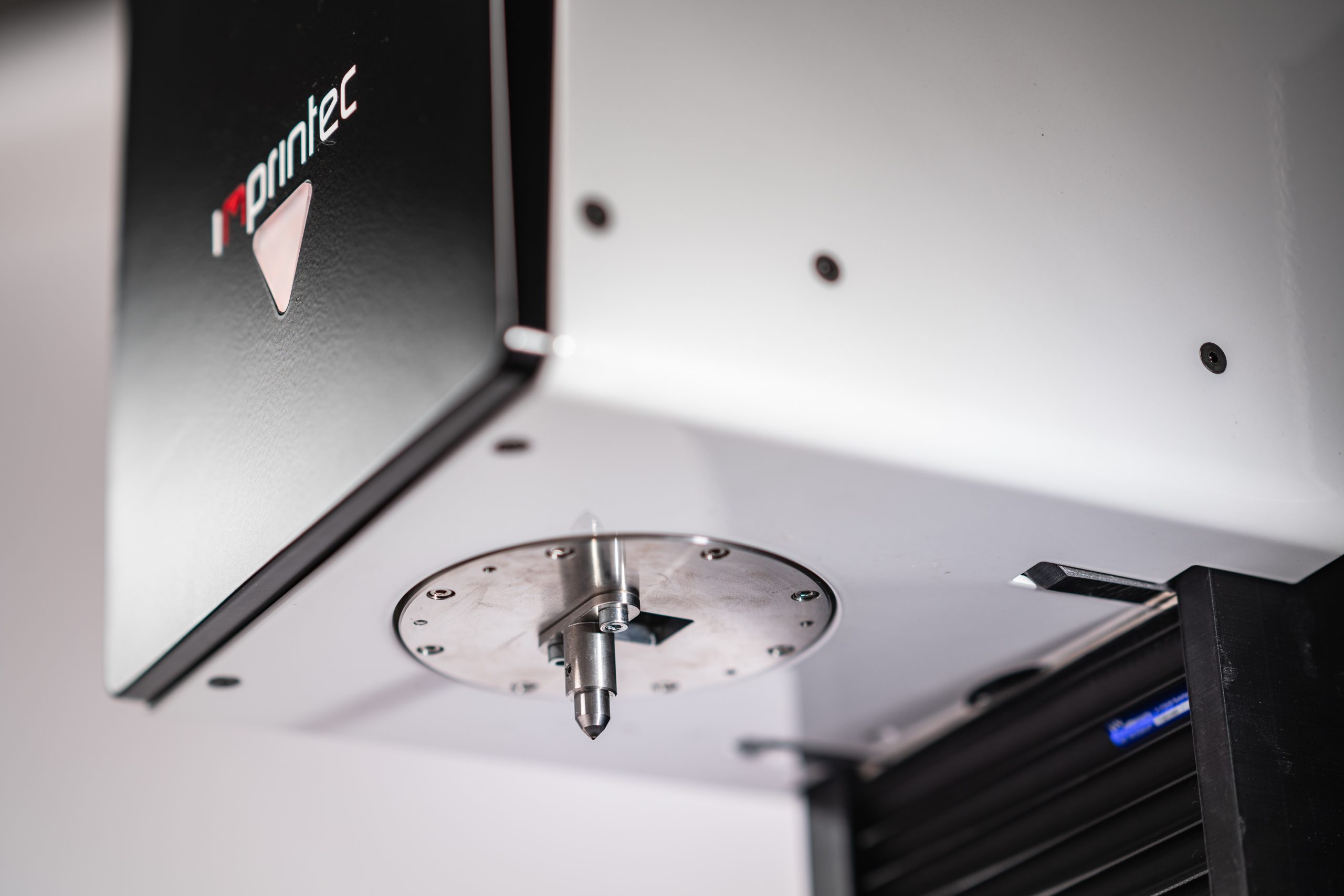

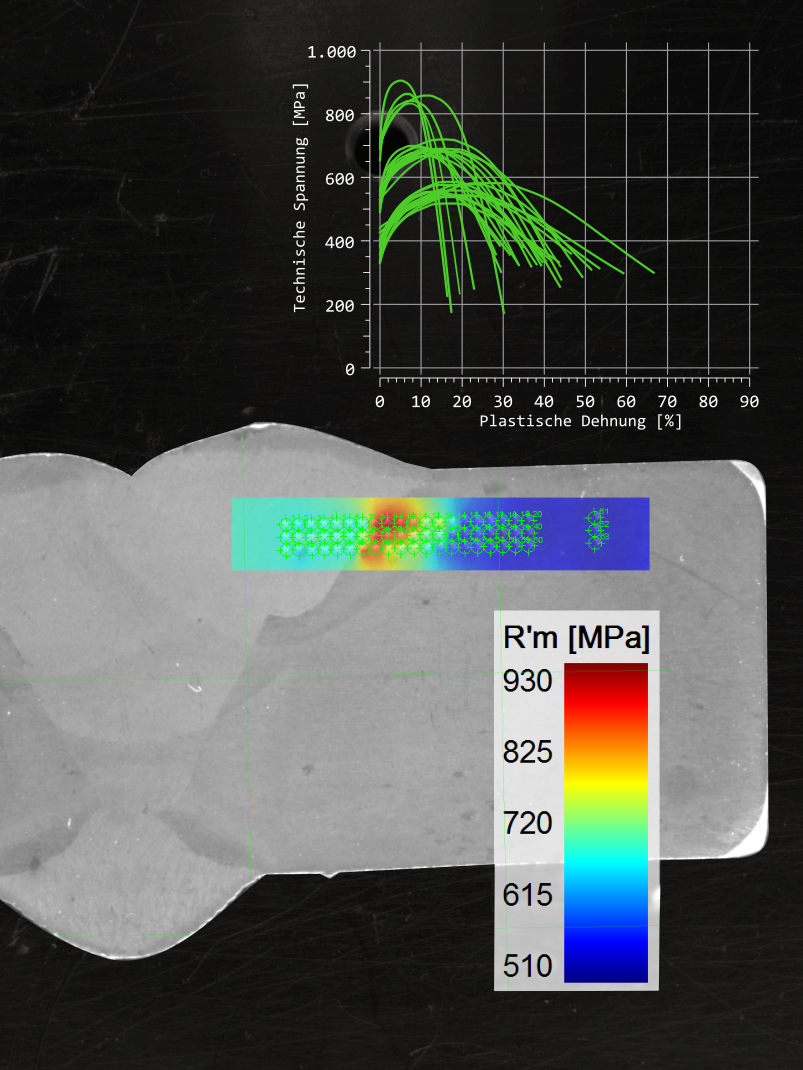

Determination of local material properties by the indentation method according to DIN SPEC 4864.

Challenge.

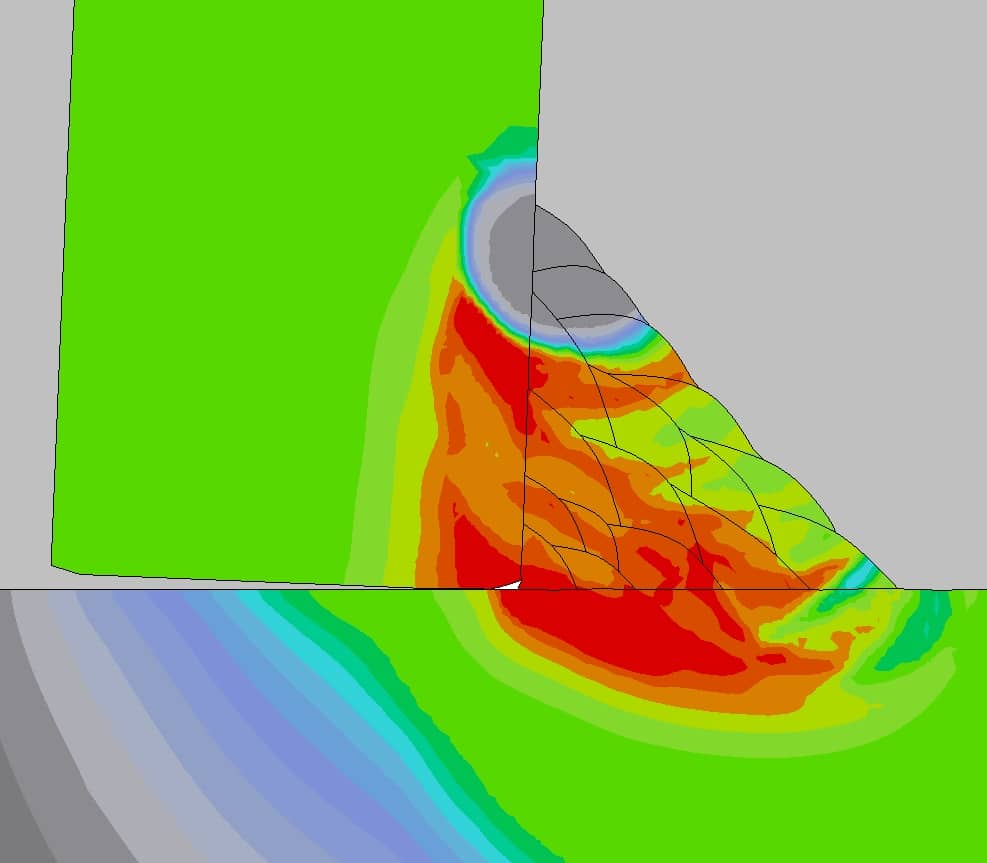

The local material properties and flow curves, e.g. for the FEM simulation with actual material data, cannot be determined according to the state of the art. The local properties have a decisive influence on the performance of a component and should often be specifically adjusted by cold forming and heat treatment. Local material properties are also found in welds and joints. Appropriate methods for the precise local characterisation of the mechanical properties are also lacking in the solution of damage cases or in the determination of the local degree of deformation.

Procedure.

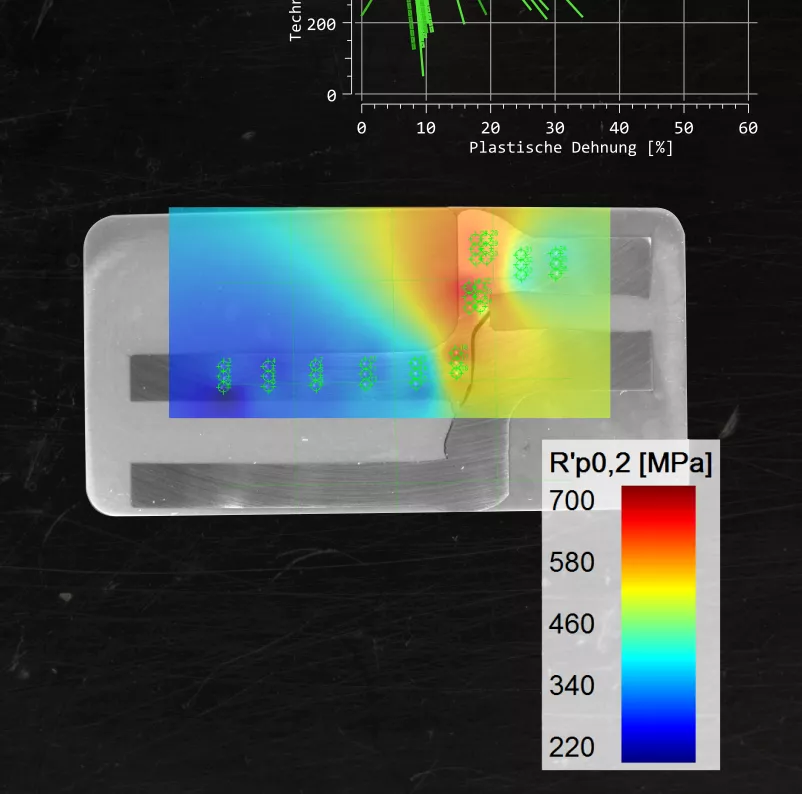

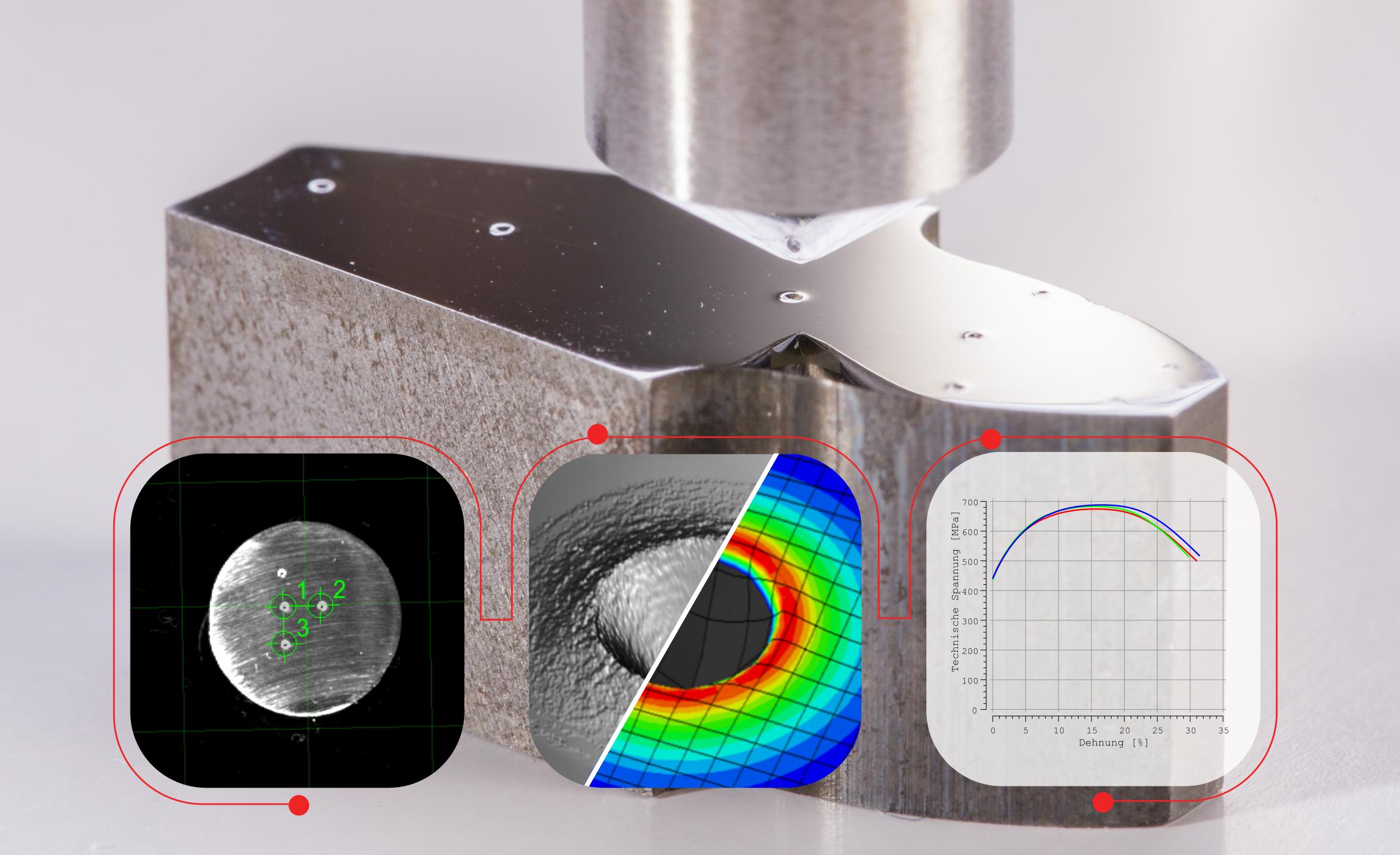

The indentation method provides local properties in the form of a stress-strain curve. Here, both the technical and the true stress curve are available to the user. By applying a measuring grid to a component sample, a large amount of data is generated. This data can be conveniently exported for further use in other analysis programs, e.g. FEM simulation programs or Excel/Minitab. The local component coordinates for each flow curve can also be exported.

Results.

The use of local material properties can be used to optimise manufacturing processes and parameters. The rapid optimisation and control of mechanical properties provides a unique toolset.

Conclusion.

The indentation process is a flexible and high-quality tool for a variety of questions in research and development, optimisation of components and processes. It leads to deeper process knowledge in further analysis.

Our products.

Our testing machines offer the measurement of 0.2% offset yield strength, ultimate tensile strength, ductility as well as the stress-strain curve – with conventional hardness testing on request.