Determination of mechanical parameters and hardness values.

i3D R/BVR

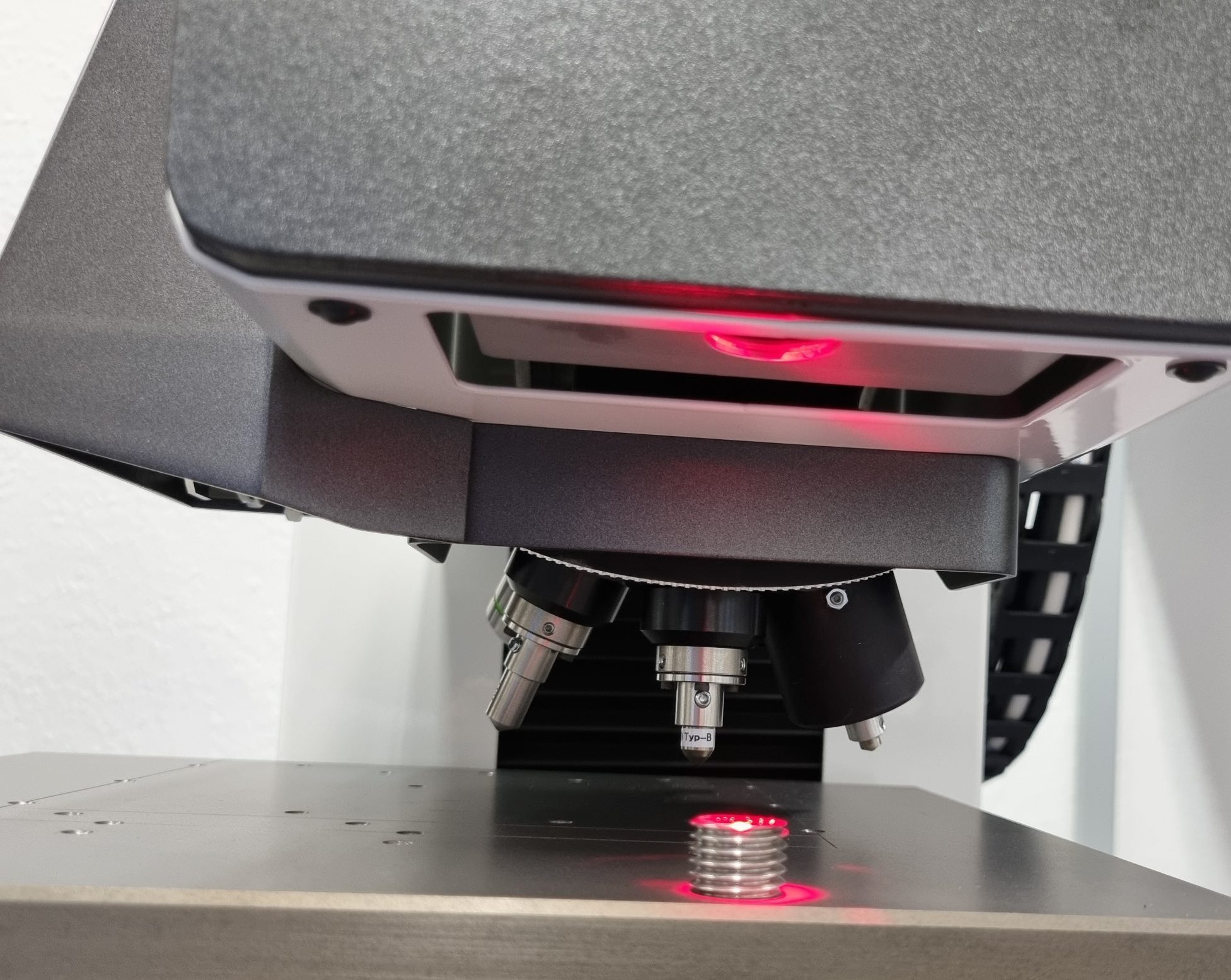

- High-precision optical 3D measurement of surfaces.

- Standardised hardness test (Brinell, Vickers and Knoop).

- Determination of Stress-strain curves and mechanical properties from hardness indentations using an indentation method.

Hardness test according to standard

(Brinell, Vickers, Knopp).

Easy to use

due to optimised UX.

3D measurements for highest

precision.

Fully automated in 30-90

seconds.

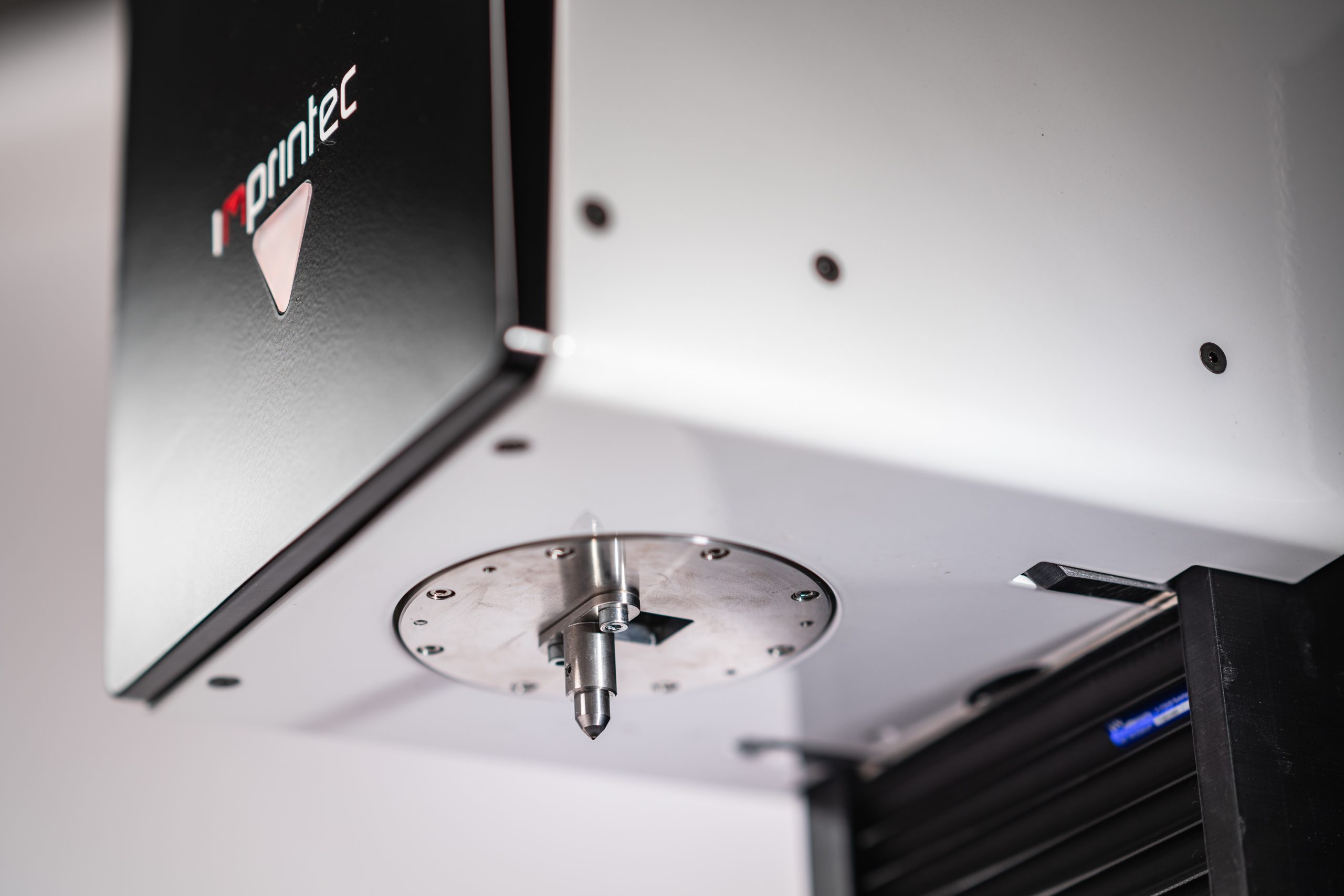

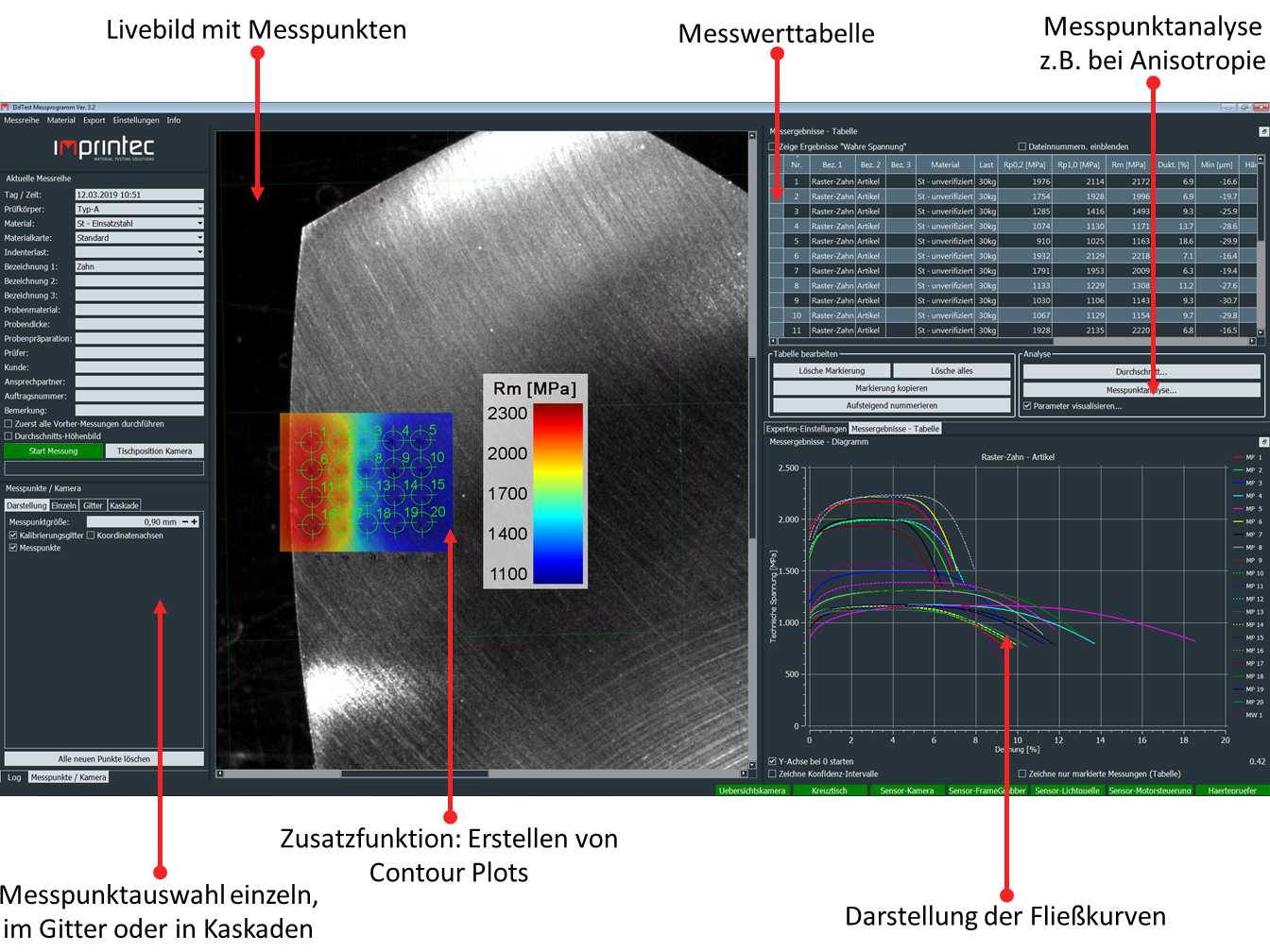

The i3D testing software.

Full control and easy operation Measuring points can be set individually or by grid*. The test sequence is fully automated with continuous progress display.

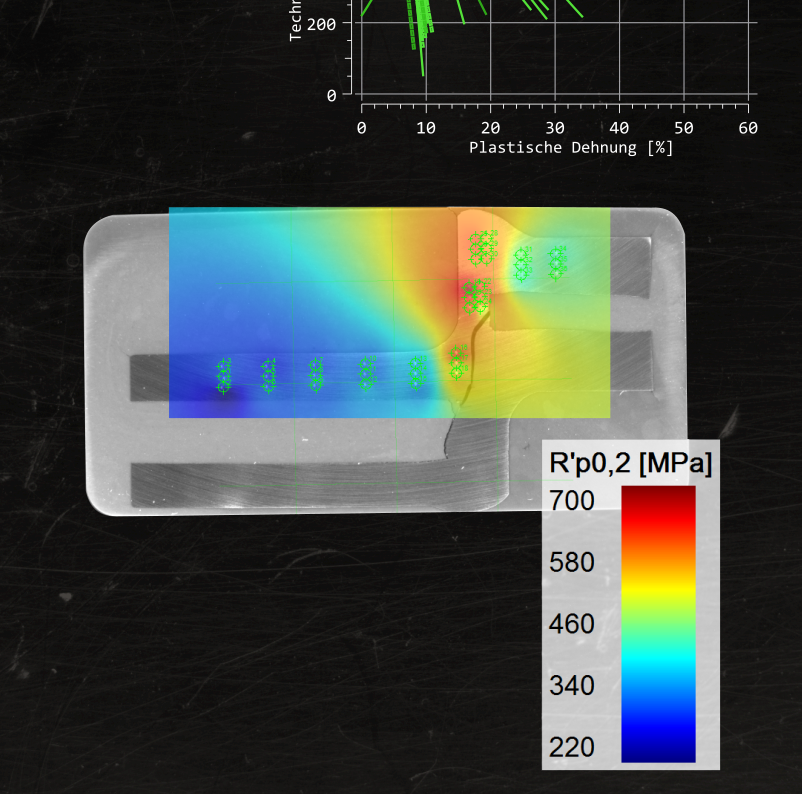

The archiving of the results and creation of test reports are generated automatically. In addition, the stress-strain curves can be exported with the respective location coordinates. Furthermore, the anisotropy of the material can be visualised in addition to the output of the mechanical parameters hardness, ultimate tensile strength and 0.2% offset yield strength.

The classic Rockwell, Brinell or Vickers hardness testing methods according to the norm are also standard. Two machine types are available:

- Maschine i3D R: Imprint method + Rockwell

- Maschine i3D BVR: Imprint method + Brinell + Vickers + Rockwell

Laboratory and production.

The i3D BVR is suitable for use both in the test laboratory and at production-related locations in the factory. Appropriate solutions for vibration damping are available for this purpose.

Contact us