Optimal use in quality assurance.

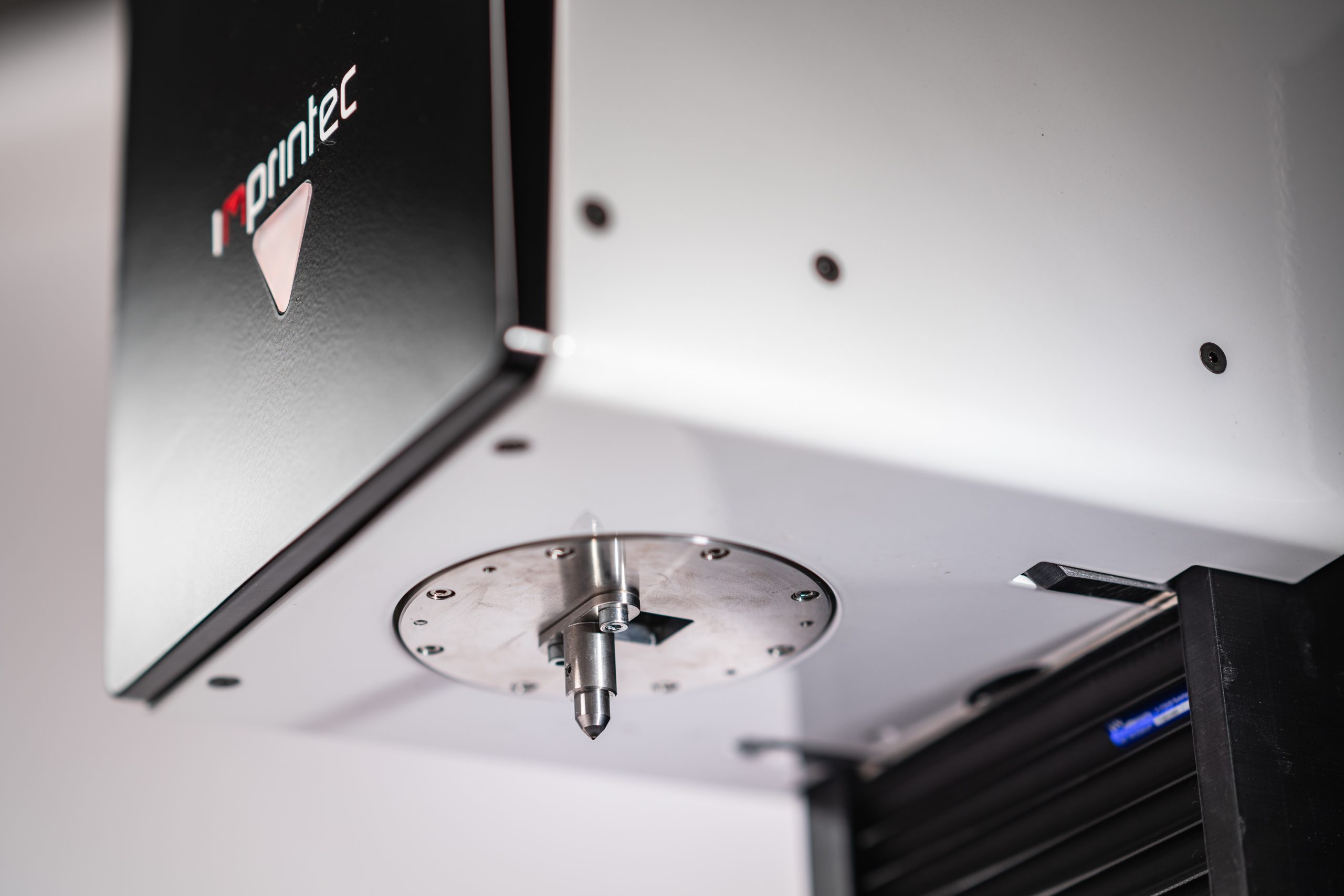

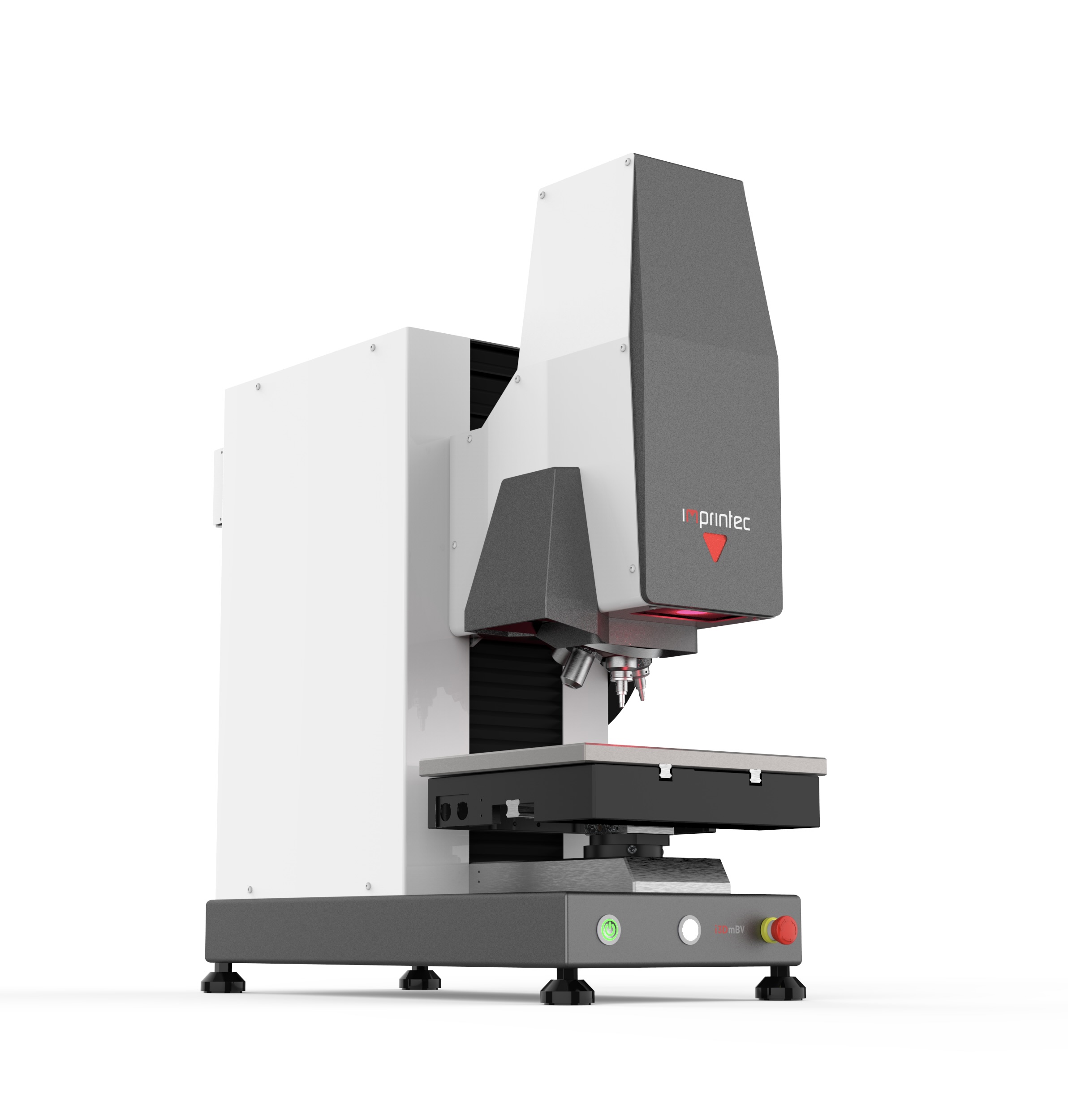

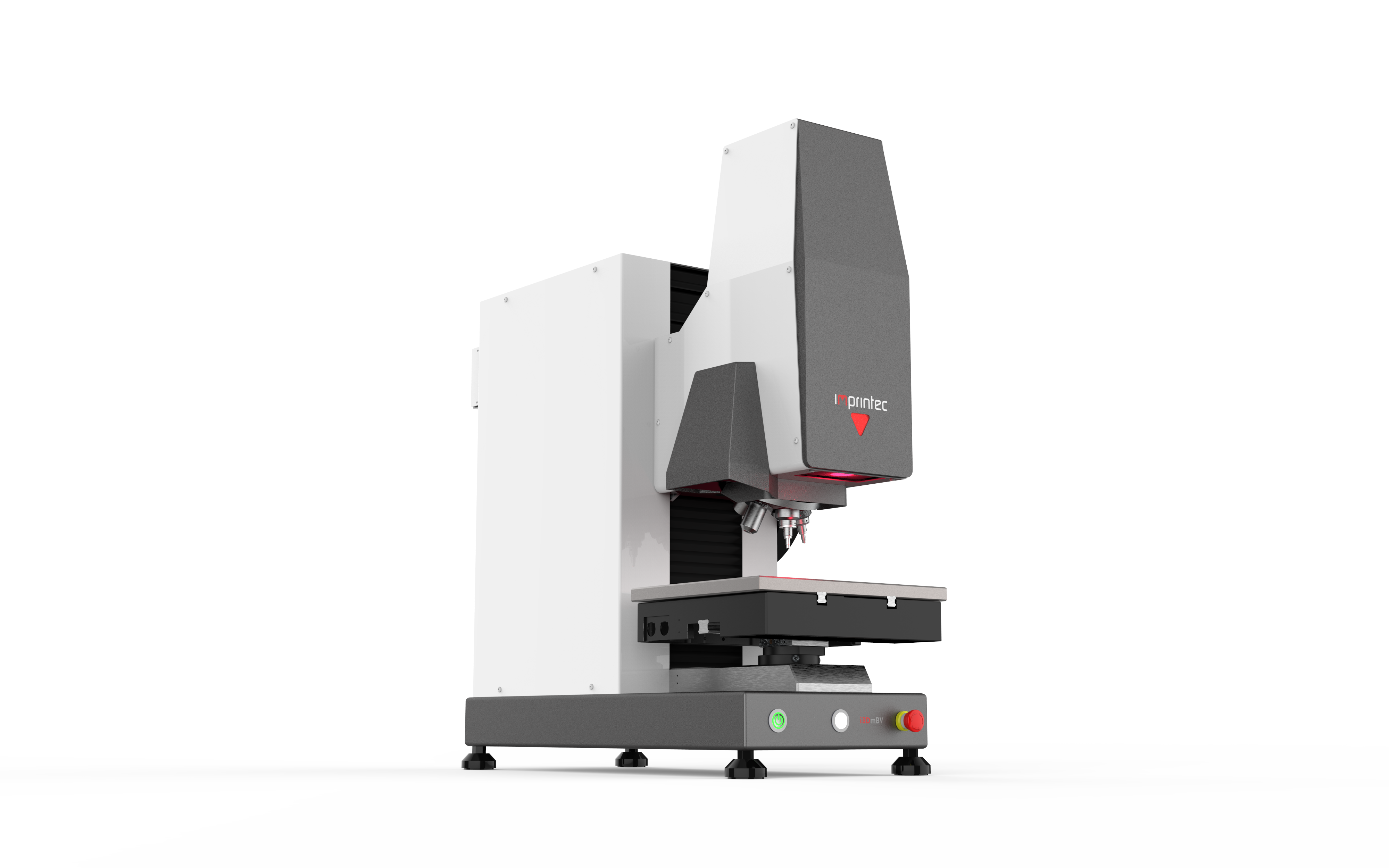

i3D mBV

Up to 3-in-1 for your quality assurance: tensile test characteristics, universal hardness testing and optical measurement technology in one device.

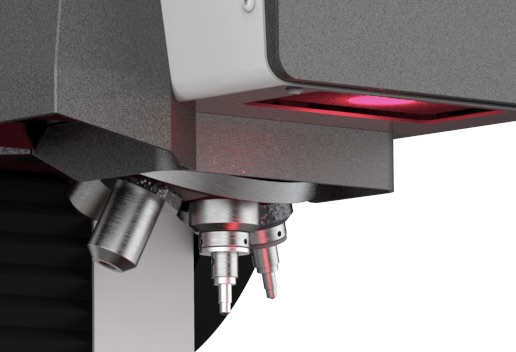

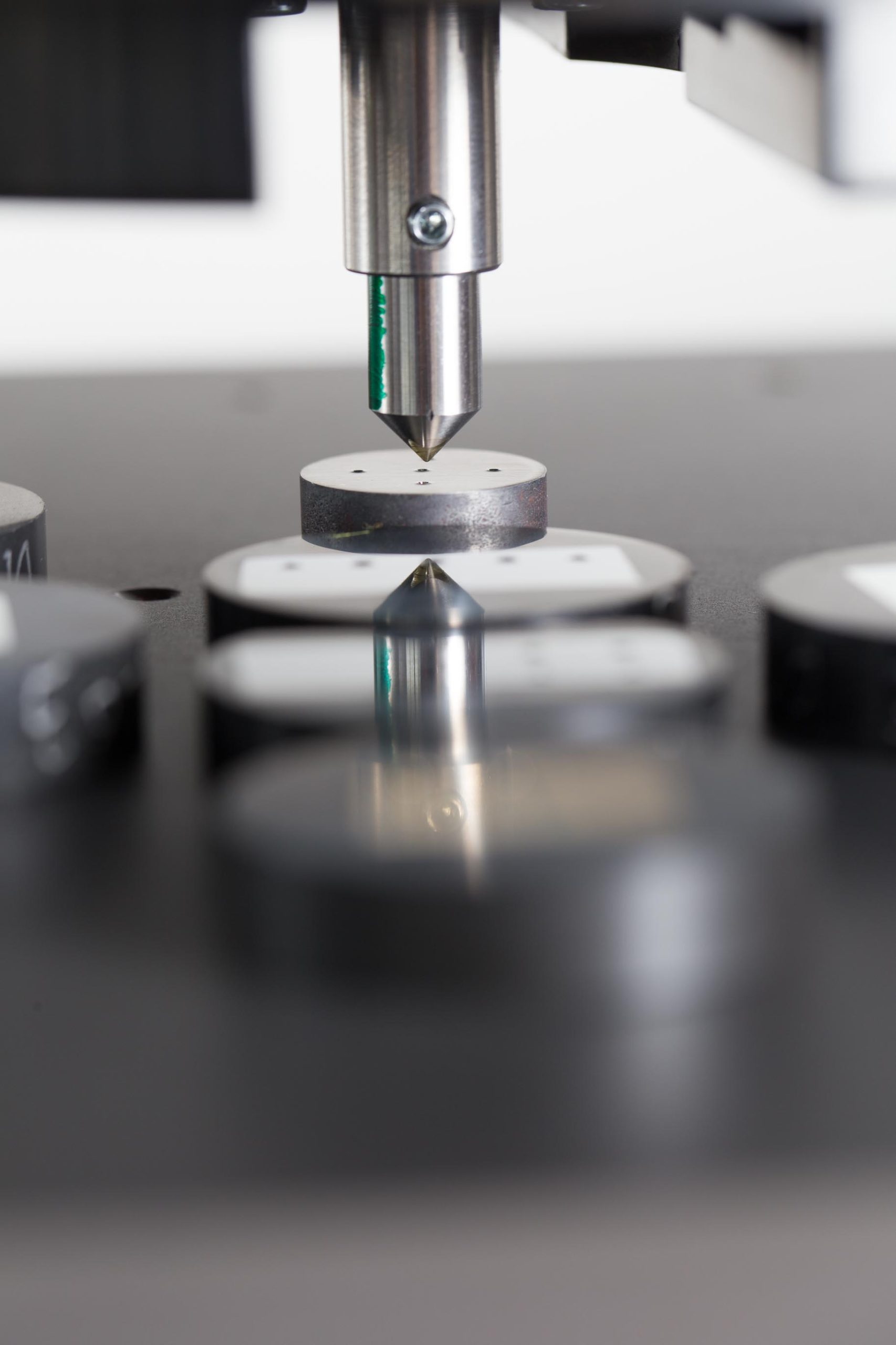

- High-precision optical 3D measurement of surfaces.

- Standardised hardness test (Brinell, Vickers and Knoop).

- Determination of Stress-strain curves and mechanical properties from hardness imprints using an indentation method.

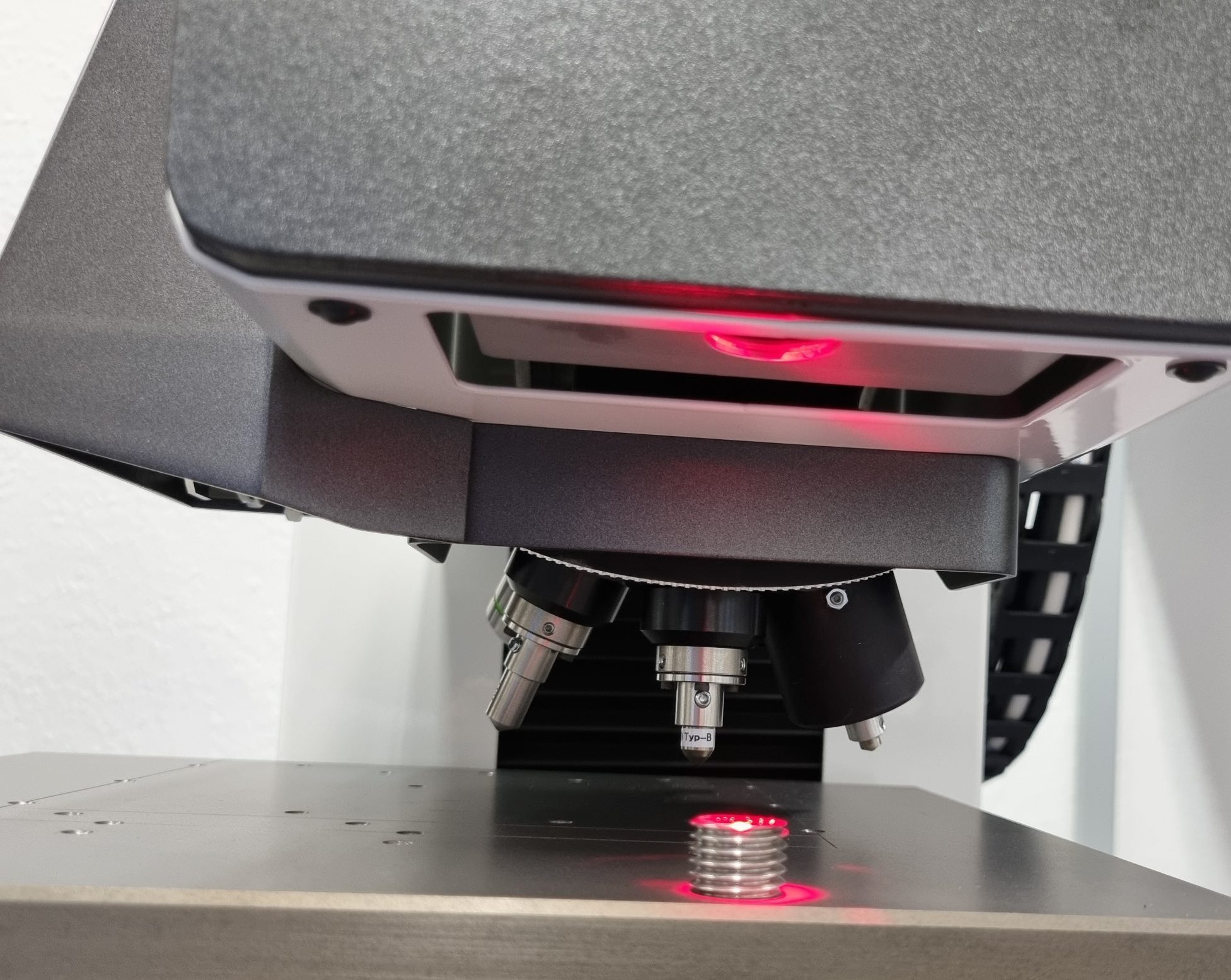

Hardness testing, indentation method according to DIN SPEC 4864 and optical measuring technology in one device.

Stress-strain curves and mechanical parameters within 90 seconds. The device is supplemented by standard-compliant hardness testing according to Vickers, Brinell and Knoop. On request, optical measurement technology can be added for geometry and roughness measurement.

Three tests and measurement

technologies combined.

Individually configurable.

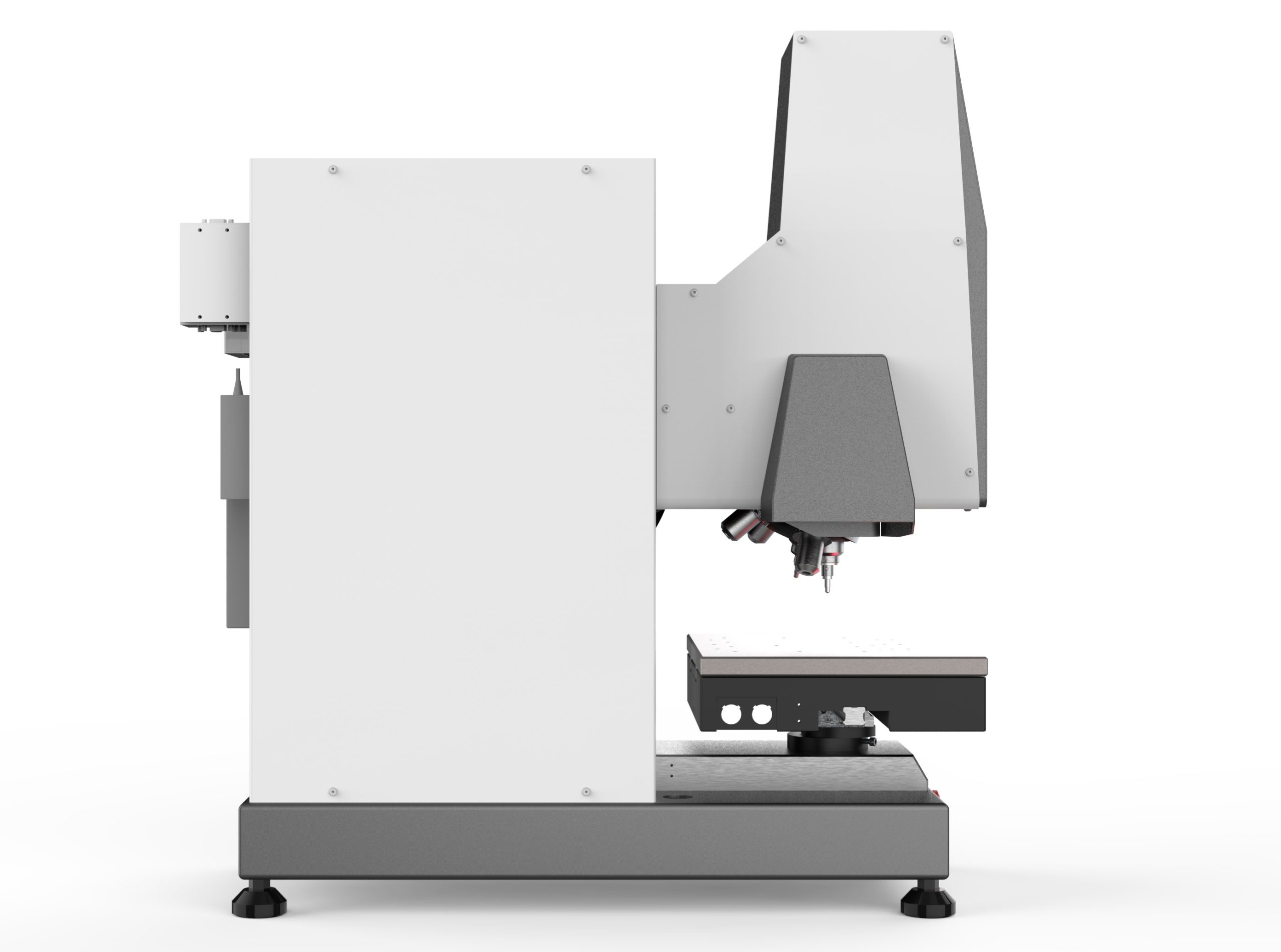

Innovative design.

Space-saving.

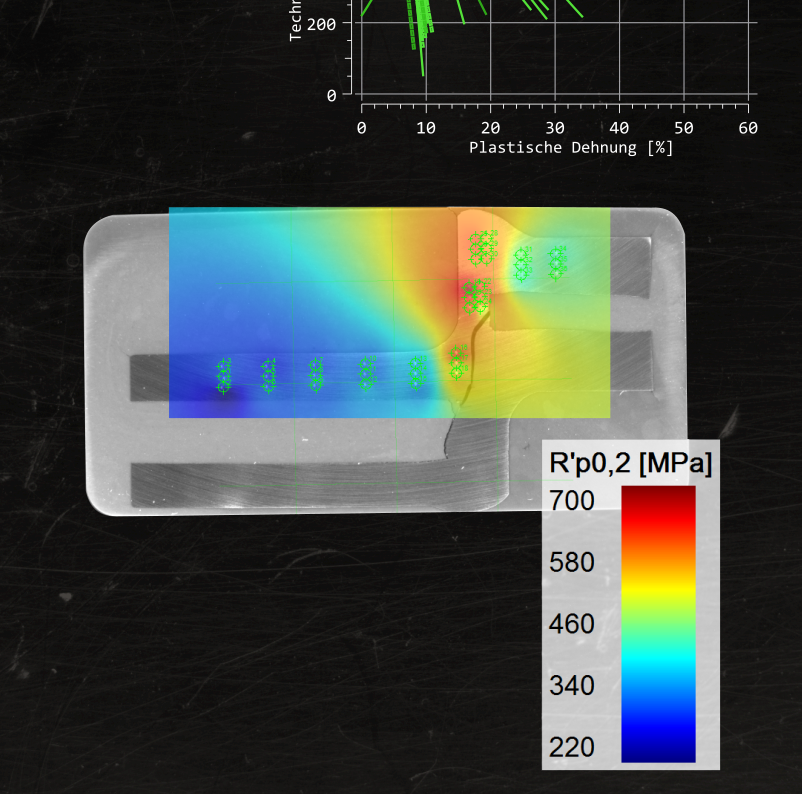

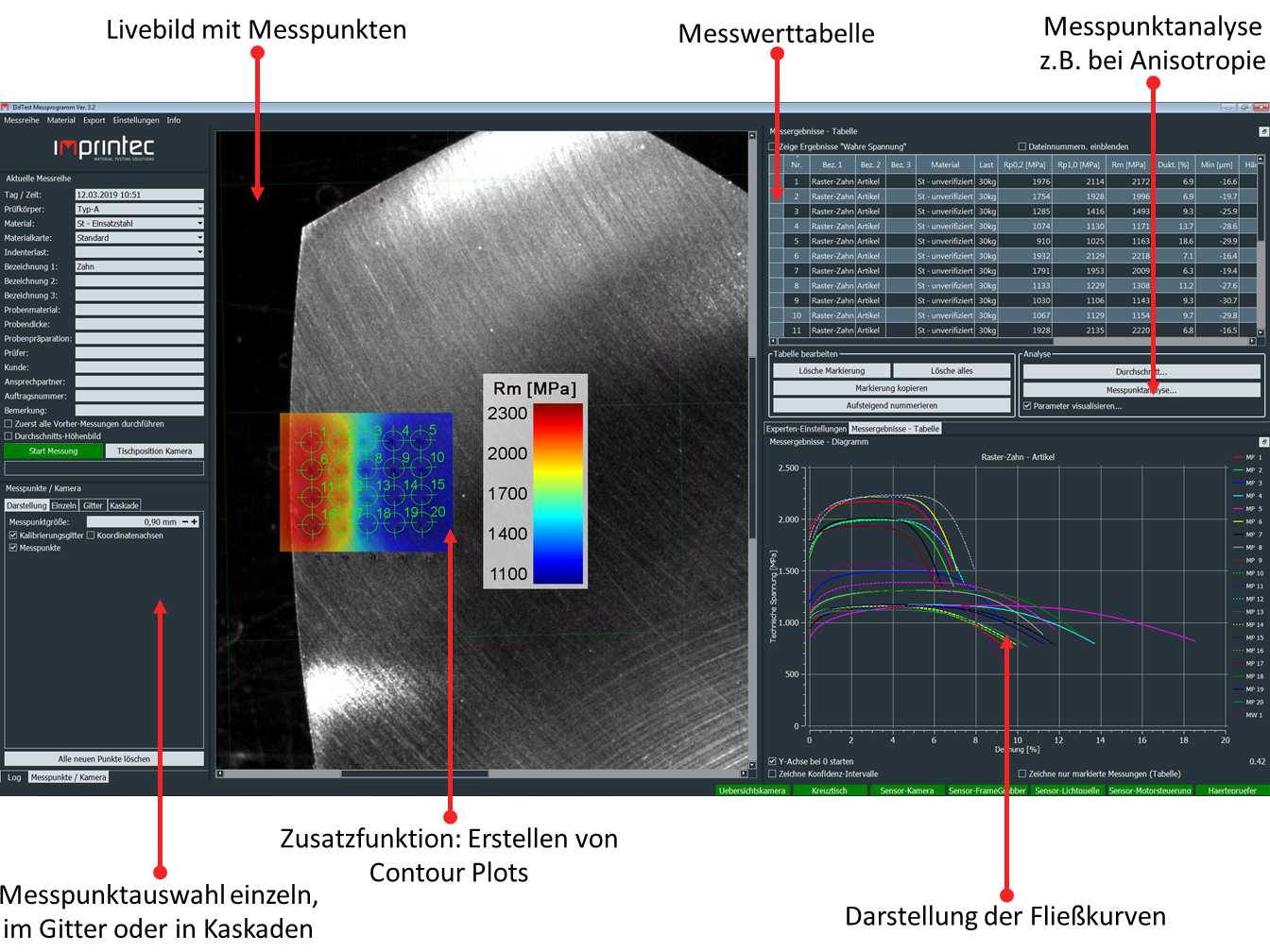

The i3D testing software.

Full control and easy measuring points operation can be set individually or by grid. The test sequence is fully automated with continuous progress display.

The archiving of the results and creation of test reports are generated automatically. In addition, the flow curves can be exported with the respective location coordinates. Furthermore, the anisotropy of the material can be visualised in addition to the output of the mechanical parameters hardness, tensile strength and yield strength.

Indentation process, hardness testing and 3D measurement technology.

Combine up to three units in one to save space.

Research and development.

The ideal testing system for many mechanical issues in the field of research and development.

Contact us

New in 2023.

Universal and unique: Tensile test characteristics, universal hardness testing and optical measurement technology in one device.

More products.

FAQ.

What are the results of a test with the indentation method?

The results are

- Stress-strain curve

- 0.2% offset yield strength

- Ultimate tensile strength

- Ductility (possible as uniform elongation or elongation at break for selected materials)

- Anisotropy (qualitative)

Is the stress-strain curve determined as technical or true?

Both technical and true curves are calculated and can be displayed in the user interface and exported for further use.

How are these values determined?

It is a software algorithm that calculates material parameters from the three-dimensional shape of a hardness impression using FEM simulations. The method is specified in accordance with DIN SPEC 4864. The link to the standard can be found here.

Is it a mechanical test method?

The indentation is carried out mechanically on a test specimen, followed by an optical evaluation with an interferometer and calculation with an algorithm.

Can characteristic values for the anisotropy of materials be determined?

Normally, these can only be determined qualitatively. However, they can also be calculated quantitatively for individual applications.