Prüfungen von Bauteilen und Fügeverbindungen.

Werkstoffprüfung.

Werkstoffprüflabor zur Durchführung des Eindruckverfahrens nach DIN SPEC 4864.

- Prüfung von wärmebehandelten Bauteilen.

- Lokale Prüfung von Fügeverbindungen z.B. Schweißnähten.

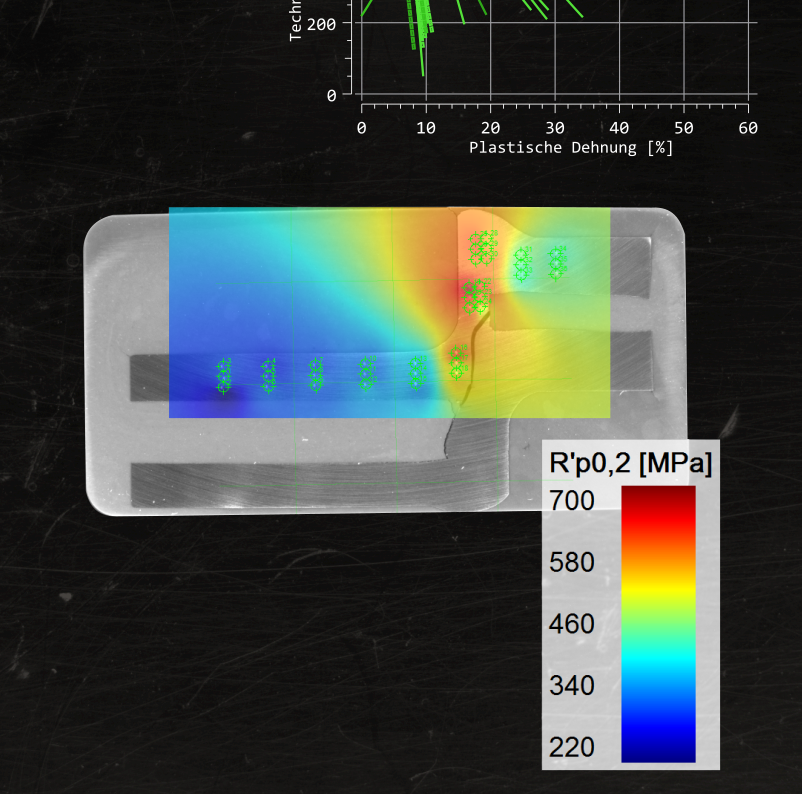

- Bereitstellung von Fließkurven für die FEM-Simulation.

Zerstörungsarme und

punktgenaue Prüfung.

Prüfstellen mit geringen

Abmessungen prüfbar.

Prüfung aller Metalle (Stahl,

Nickel, Aluminium…).

Ermittlung lokaler Fließkurven

als Basis für Simulationen.

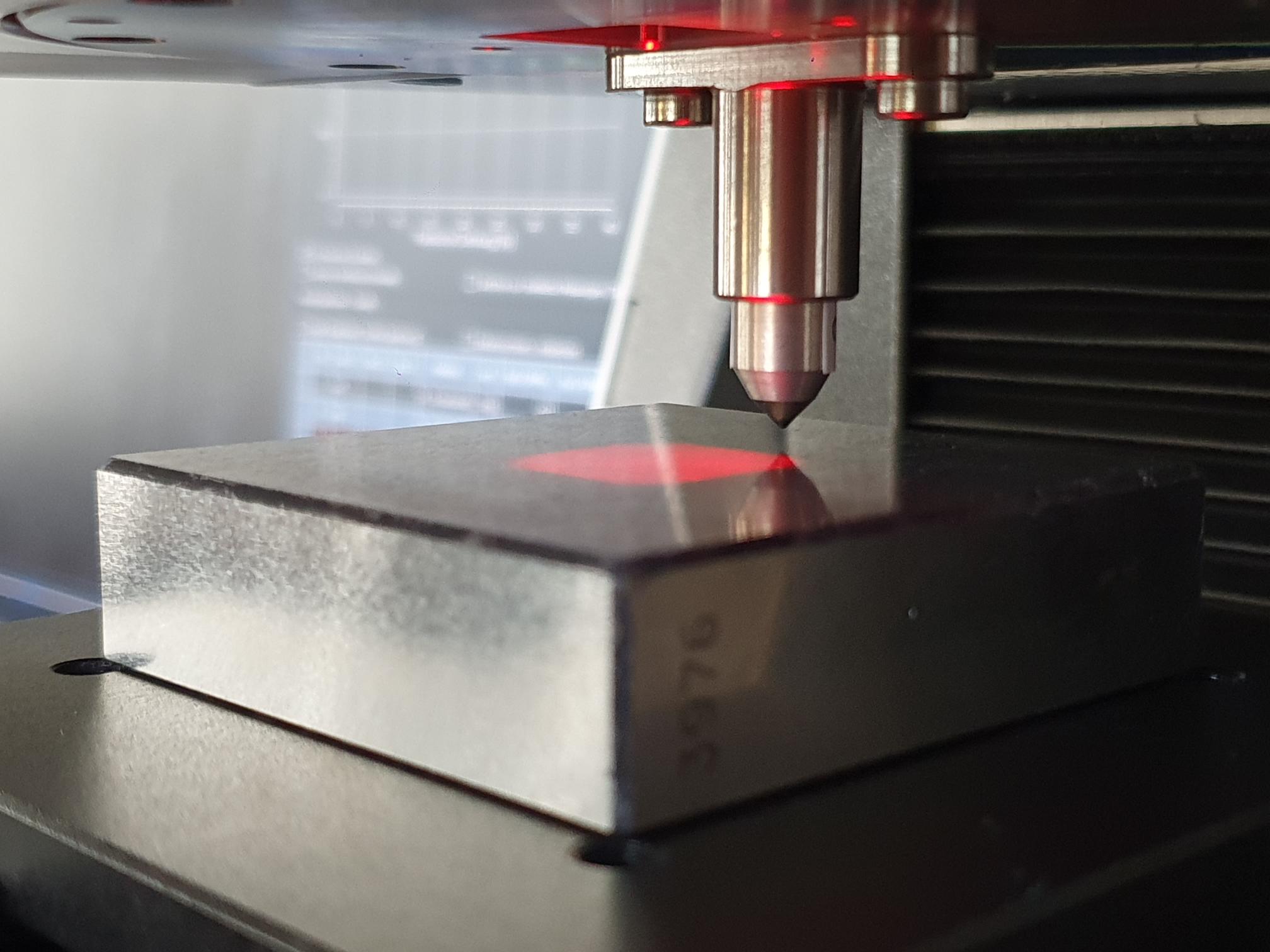

Modernste Technik im Werkstoffprüflabor.

Wer bisher Informationen über Qualität, Zustand oder Tauglichkeit eines Werkstoffes für einen bestimmten Einsatzzweck benötigte, stand vor der Herausforderung, dass eine Härteprüfung allein nicht alle wichtigen Kennwerte lieferte und die Umwertungstabelle für Härtewerte und Zugfestigkeit nach DIN EN ISO 18265 nur mit Einschränkungen zu nutzen ist. Ein Zugversuch, der detaillierte Aussagen zum Werkstoff liefert, muss aufwendig vorbereitet werden und führt zur Zerstörung der Probe.

Im Imprintec Werkstoffprüflabor arbeiten unsere Spezialisten mit dem innovativen und patentierten Eindruckverfahren nach DIN SPEC 4864, mit dem bereits ein Messpunkt die gewünschten mechanischen Kennwerte (RIp0,2* und RIm*) liefert.

Nutzen von Laborprüfungen mit Eindruckverfahren.

In vielen Fällen können wir Sie bei der Entwicklung und der Qualitätssicherung Ihrer Bauteile unterstützen. Sie schaffen damit eine Lösung zur Prüfung Ihrer Teile, bei denen Sie bisher keine Zugproben entnehmen können oder die fehlende Aussage zur 0,2%-Dehngrenze Rp0,2 und Zugfestigkeit Rm bei verschiedenen Metallen durch Härteumwertung nicht abgedeckt wird.

Erleben Sie die Verbesserung in unserem Werkstoffprüflabor selbst – vereinbaren Sie einen Termin in Bochum und lassen Sie sich zu den individuellen Vorteilen für Ihr Unternehmen informieren.

Häufige Fragen zu unserem Werkstoffprüflabor

Welchen Mehrwert bietet das Eindruckverfahren gegenüber anderer Verfahren?

- Zerstörungsarm

- Punktgenaue Prüfung von der 0,2%-Dehngrenze RIp0,2* und der Zugfestigkeit RIm*

- Prüfstellen mit geringen Abmessungen prüfbar

(Bleche, Schichten) - Ermittlung lokaler Fließkurven als Basis für FEM-Simulationen

Welche Werkstoffe können wir in unserem Werkstoffprüflabor für Sie testen?

Prinzipiell können wir die Werkstoffprüfung für alle Metalle (Stahl, Nickel, Aluminium sowie Titan- und Kupferwerkstoffe) durchführen – sprechen Sie uns individuell auf Ihre zu prüfenden Werkstoffe an.

Muss die Probe oder das Bauteil bestimmte Voraussetzungen erfüllen?

Die zu untersuchende Probe sollte die folgenden Eigenschaften aufweisen:

- Bauteilhöhe nicht höher als 350 mm

- Ober-und Unterseite sind planparallel, oder müssen sich für eine Präparation eignen

- Für optimale Ergebnisse: Neigung beider Seiten beträgt maximal ca. 2%

In welchen Lastbereichen kann geprüft werden?

Wir prüfen im Bereich von 150kg bis 5kg, das bedeutet es können z.B. auch dünne Bleche geprüft werden.

Auf Anfrage können auch Prüfungen mit individuellen Laststufen realisiert werden.