Lokale

Eigenschaften.

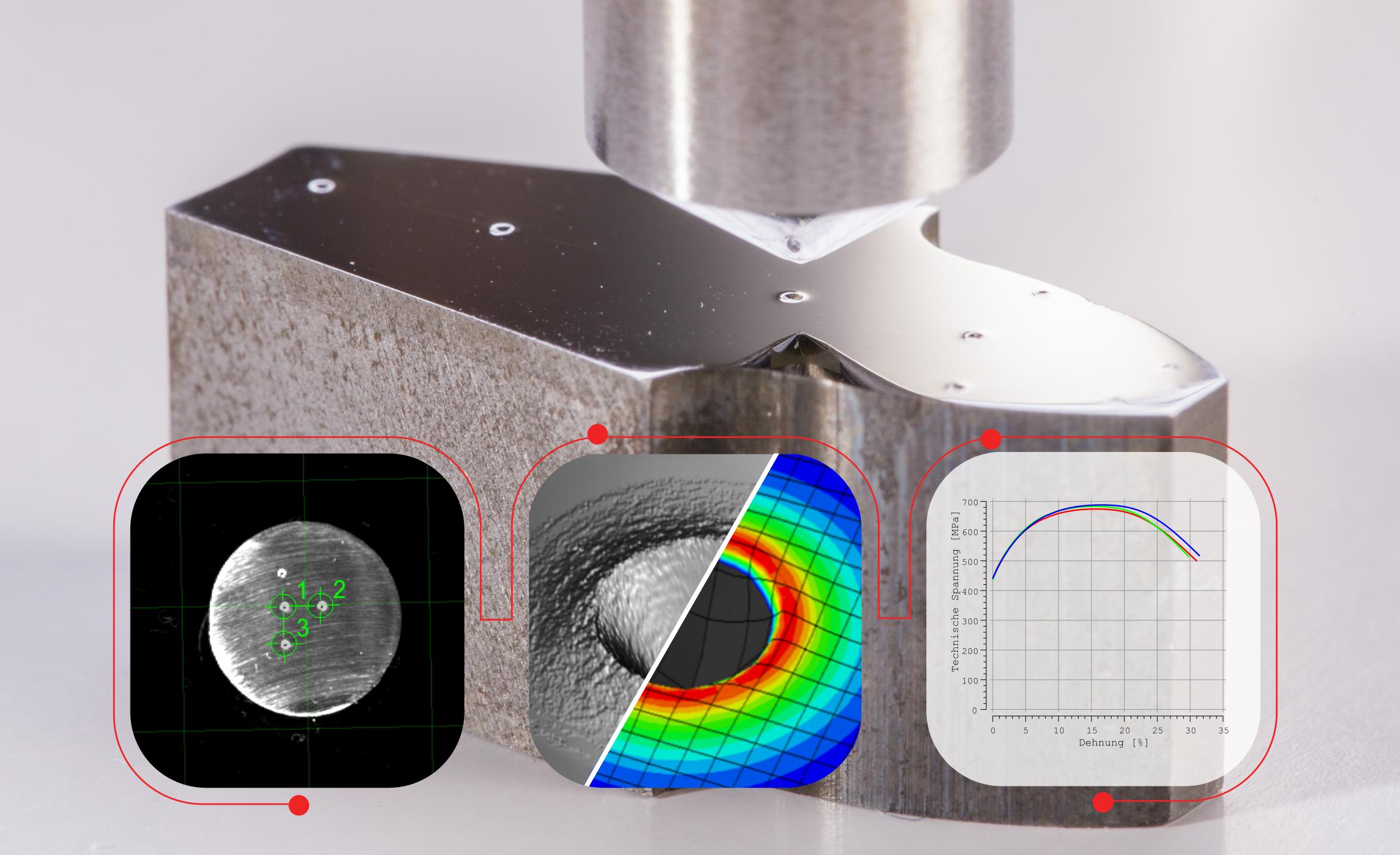

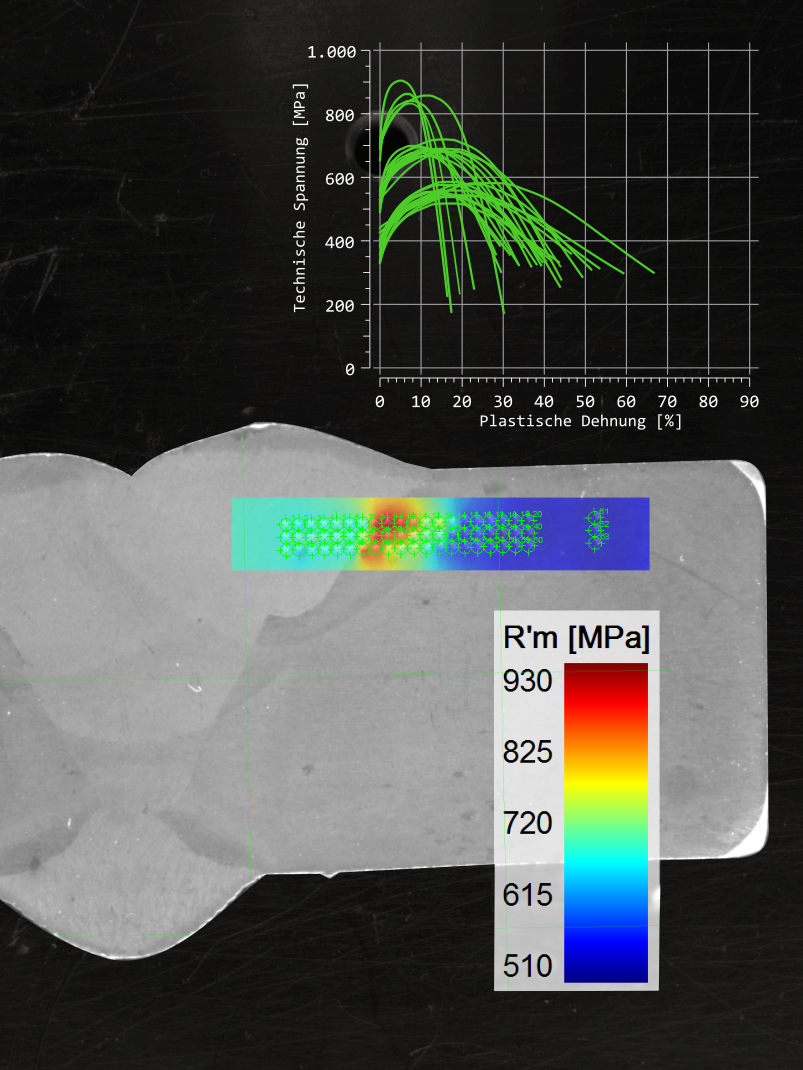

Bestimmung lokaler Werkstoffeigenschaften durch das Eindruckverfahren nach DIN SPEC 4864.

Herausforderung.

Die lokalen Werkstoffeigenschaften und Fließkurven, z.B. für die FEM-Simulation mit tatsächlichen Werkstoffdaten, können laut Stand der Technik nicht ermittelt werden. Die lokalen Eigenschaften beeinflussen die Performance eines Bauteils entscheidend und sollen oftmals gezielt durch Kaltumformung und Wärmebehandlung eingestellt werden. Lokale Werkstoffeigenschaften finden sich auch in Schweißnähten und Fügeverbindungen. Auch bei der Lösung von Schadensfällen oder zur Ermittlung des lokalen Umformgrads fehlen entsprechende Verfahren zur genauen lokalen Charakterisierung der mechanischen Eigenschaften.

Vorgehen.

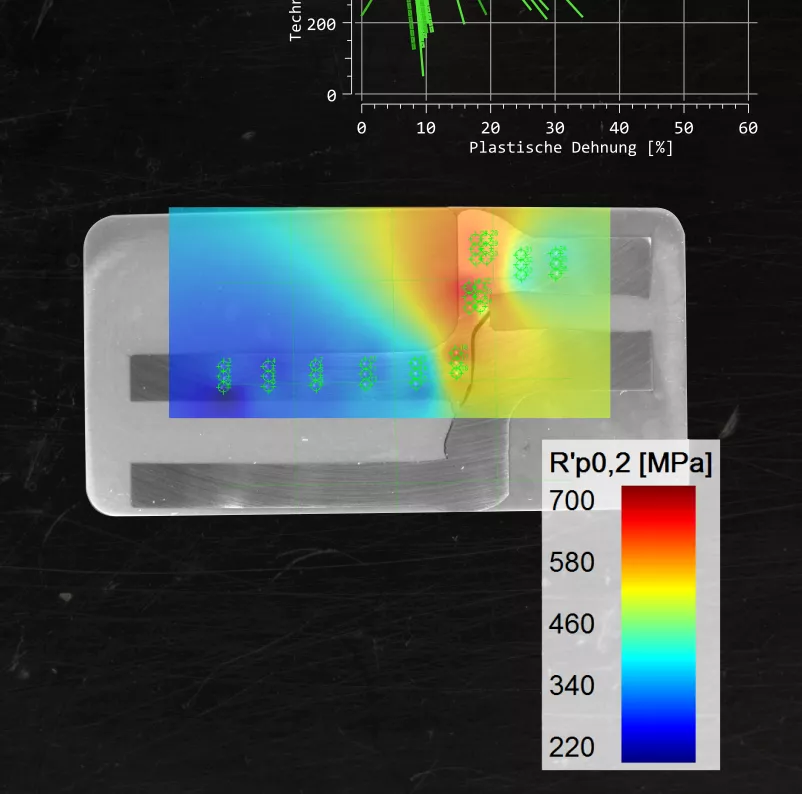

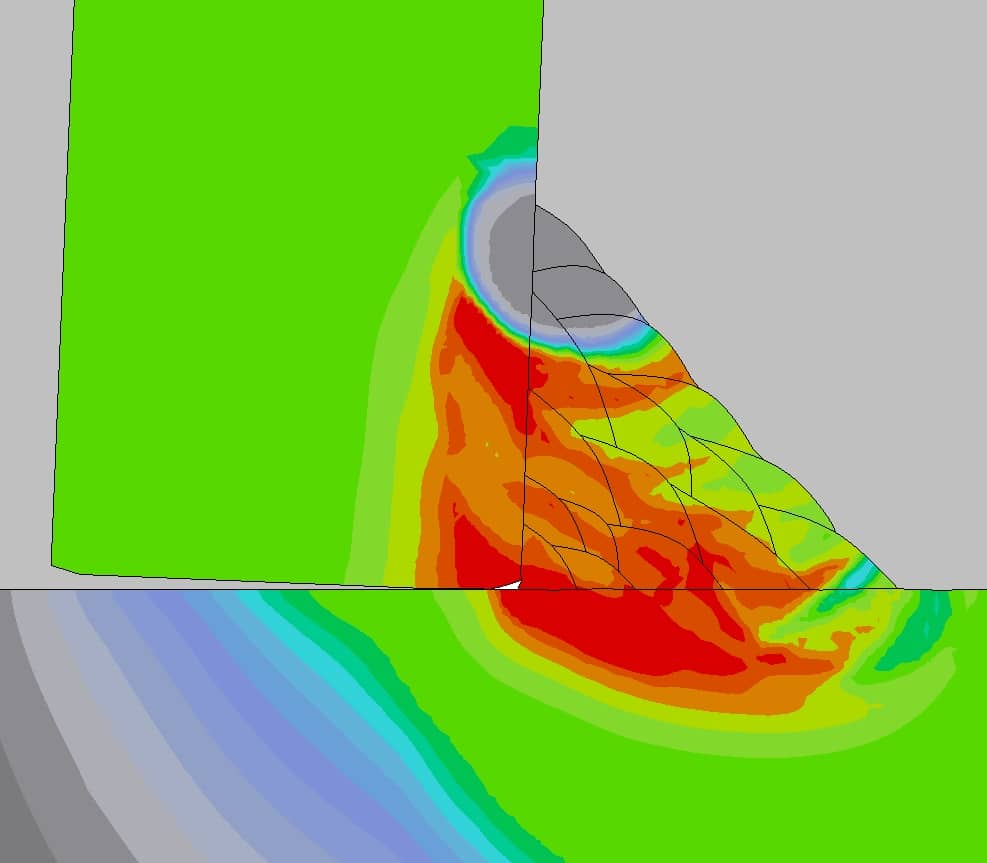

Das Eindruckverfahren liefert lokale Eigenschaften in Form einer Spannungs-Dehnungs-Kurve. Hier stehen dem Benutzer sowohl der technische als auch der wahre Spannungsverlauf zur Verfügung. Durch die Anwendung eines Messrasters auf einer Bauteilprobe wird eine Vielzahl an Daten erzeugt. Diese Daten können bequem exportiert und so in weiteren Analyseprogrammen z.B. FEM-Simulationsprogrammen oder Excel/Minitab weiter verwendet werden. Die lokalen Bauteilkoordinaten für jede Fließkurve können ebenfalls mit exportiert werden.

Ergebnisse.

Die Nutzung der lokalen Werkstoffeigenschaften kann für die Optimierung der Herstellverfahren und -parameter genutzt werden. Durch die schnelle Optimierung und Kontrolle der mechanischen Eigenschaften steht ein einzigartiges Werkzeug zur Verfügung.

Fazit.

Das Eindruckverfahren ist ein flexibles und hochwertiges Tool für eine Vielzahl an Fragen in der Forschung und Entwicklung, Optimierung von Bauteilen und Prozessen. Es führt in der weiteren Analyse zu tieferem Prozesswissen.

Unsere Produkte.

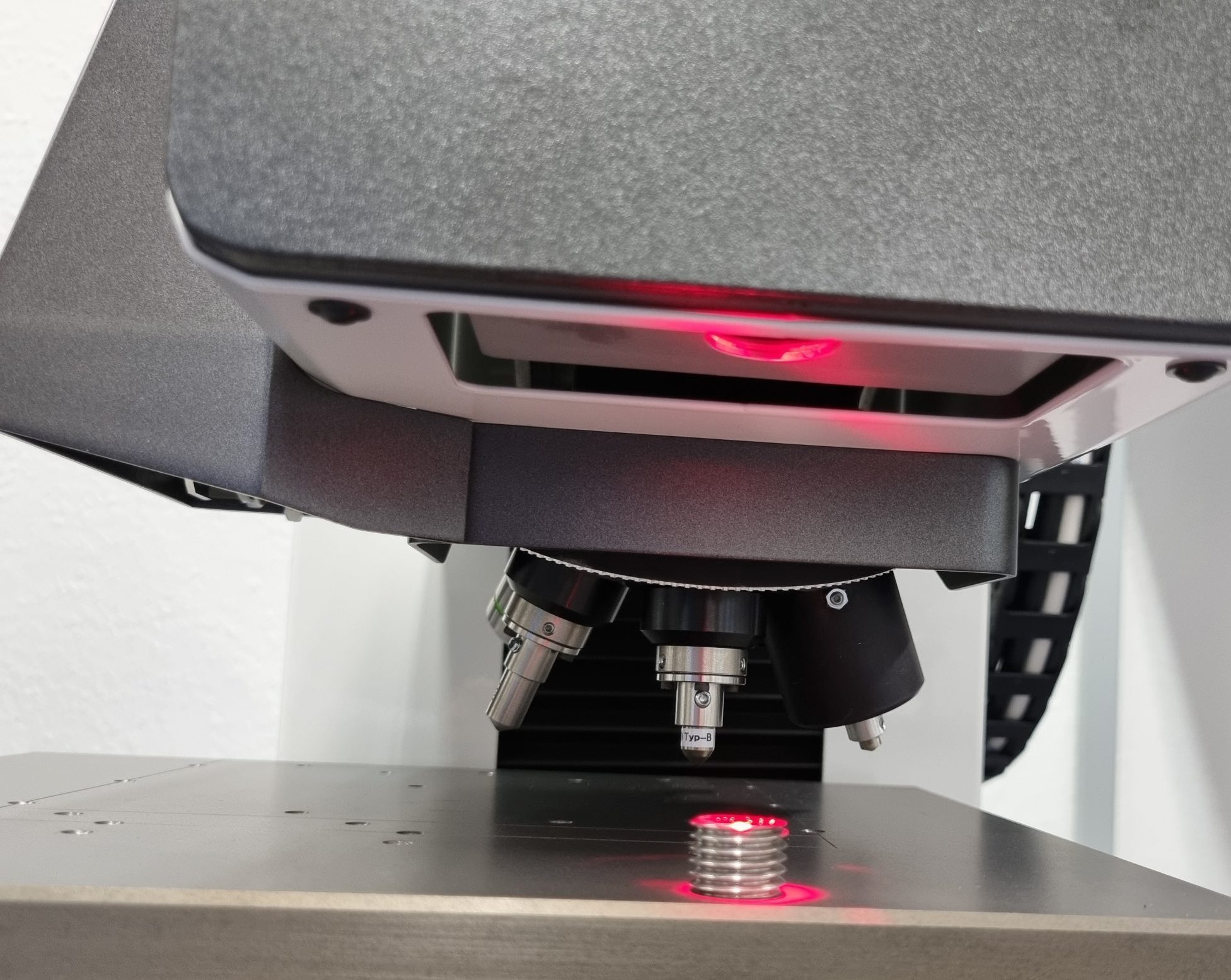

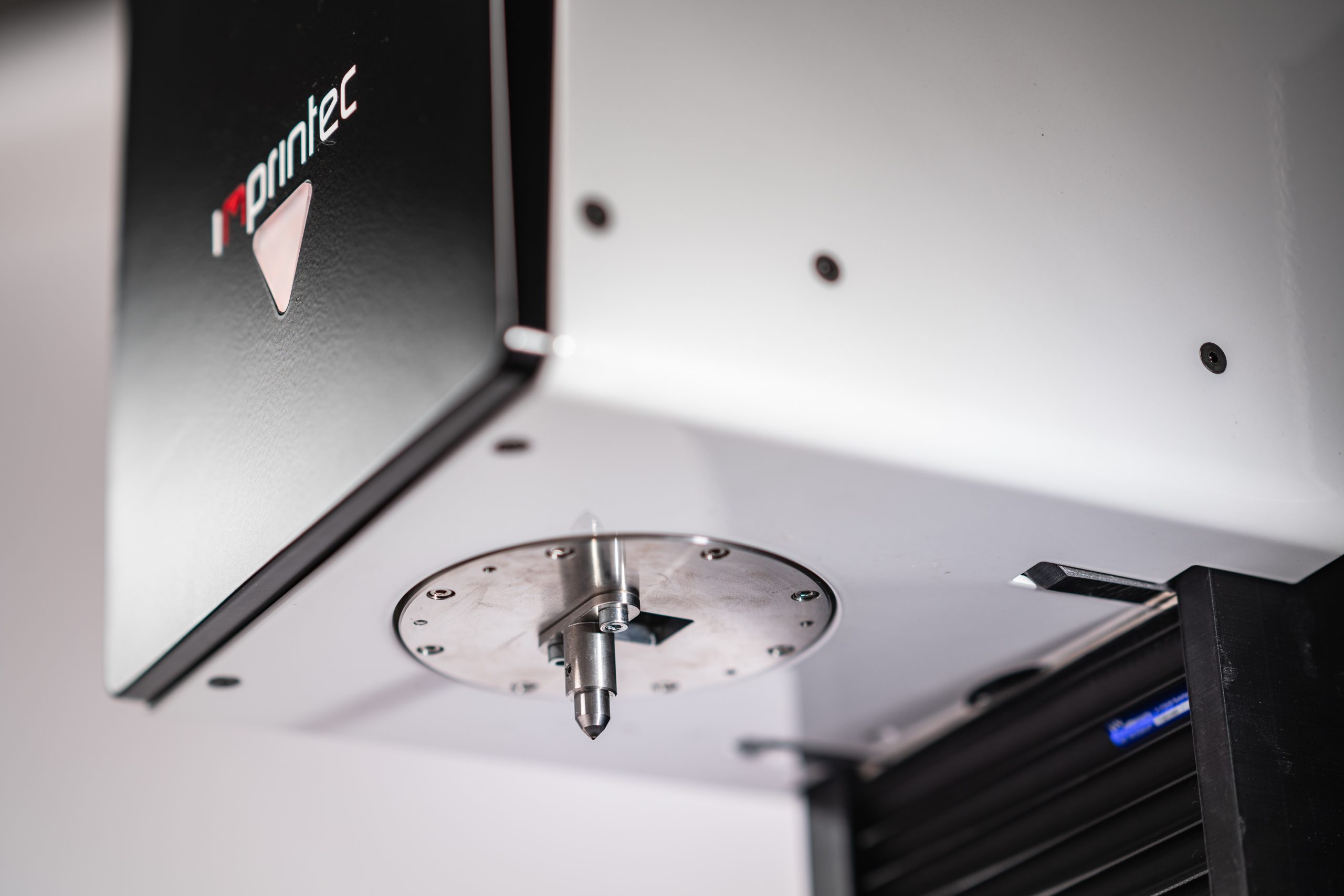

Unsere Prüfmaschinen bieten die Messung von Dehngrenze / Zugfestigkeit / Duktilität sowie der Fließkurve – auf Wunsch mit konventioneller Härteprüfung.