Testing of components and weldings.

Material testing.

Materials testing laboratory for carrying out the indentation method according to DIN SPEC 4864.

- Testing of heat-treated components.

- Local testing of joint connections, e.g. weld seams.

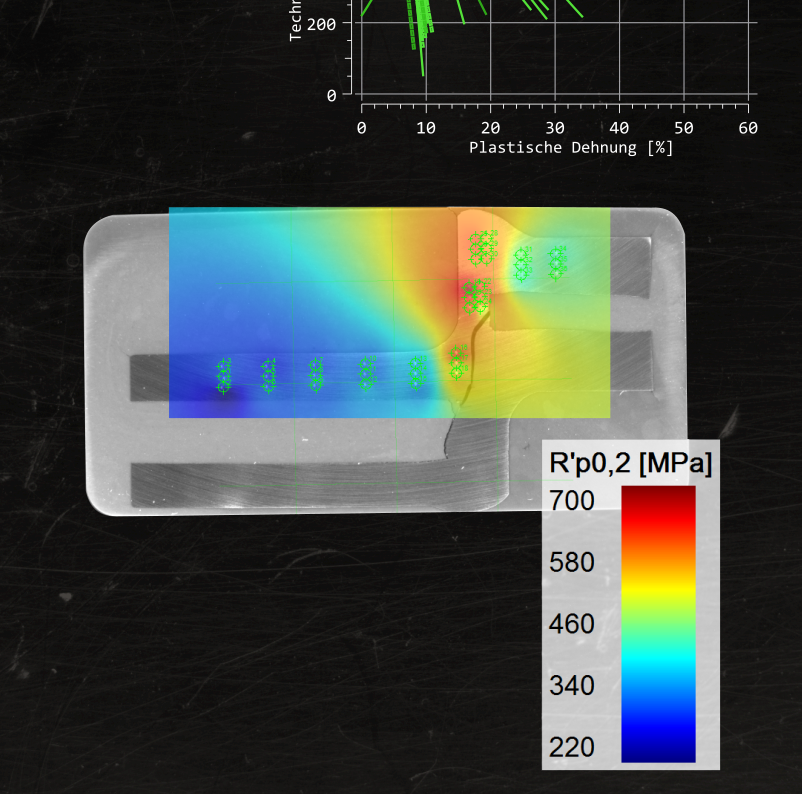

- Provision of flow curves for FEM simulation.

Low-destructive and

pinpoint testing.

Test points with small

dimensions are

testable.

Testing of all metals (steel,

nickel, aluminium...).

Determination of local stress-strain curves

as a basis for simulations.

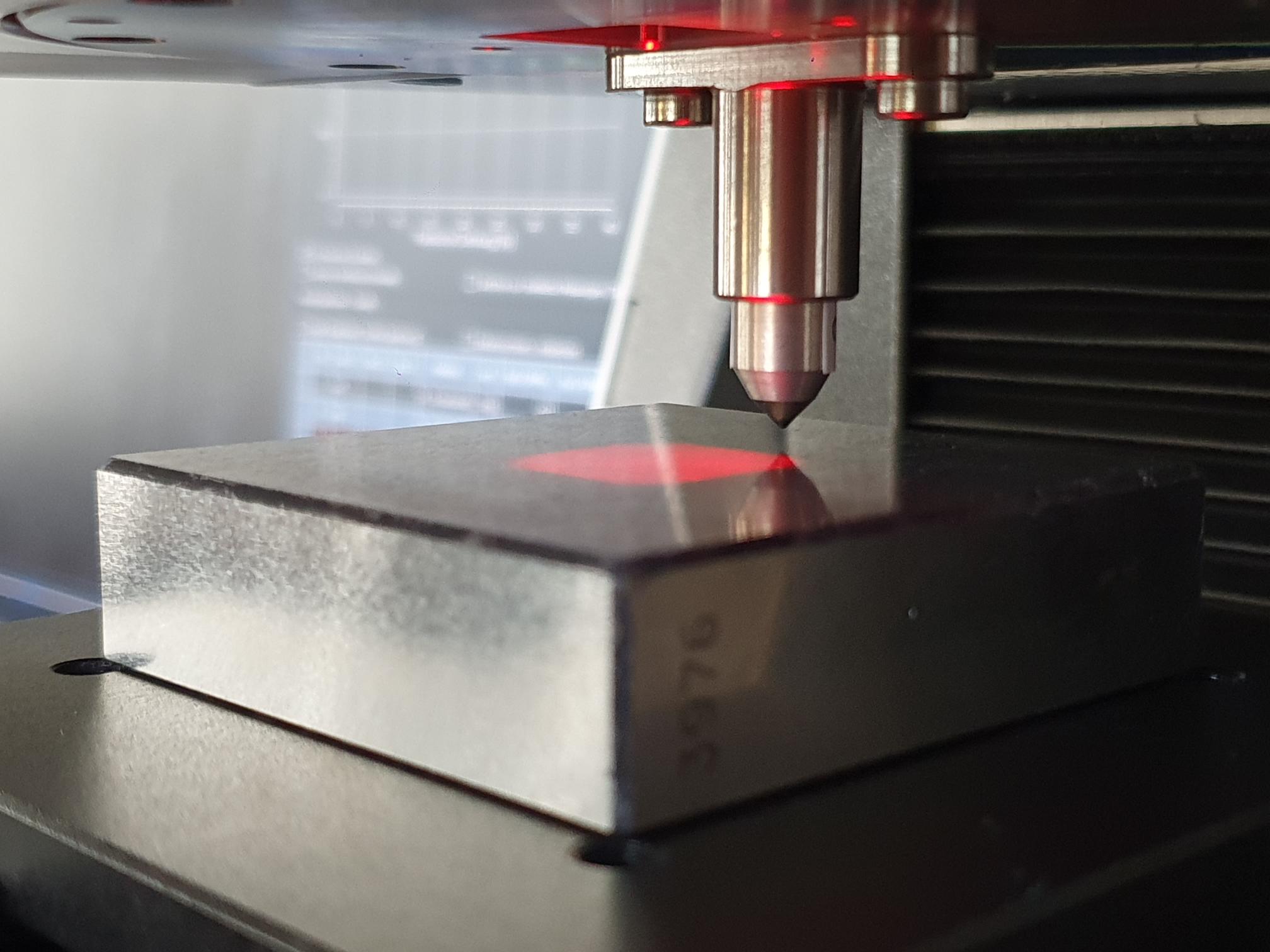

State-of-the-art technology in the materials testing laboratory.

Until now, anyone who needed information about the quality, condition or suitability of a material for a specific application was faced with the challenge that a hardness test alone did not provide. All the important characteristic values, the conversion table for hardness values and tensile strength according to DIN EN ISO 18265 can only be used with restrictions. A tensile test that provides detailed information on the material must be prepared in a time-consuming manner and leads to the destruction of the sample.

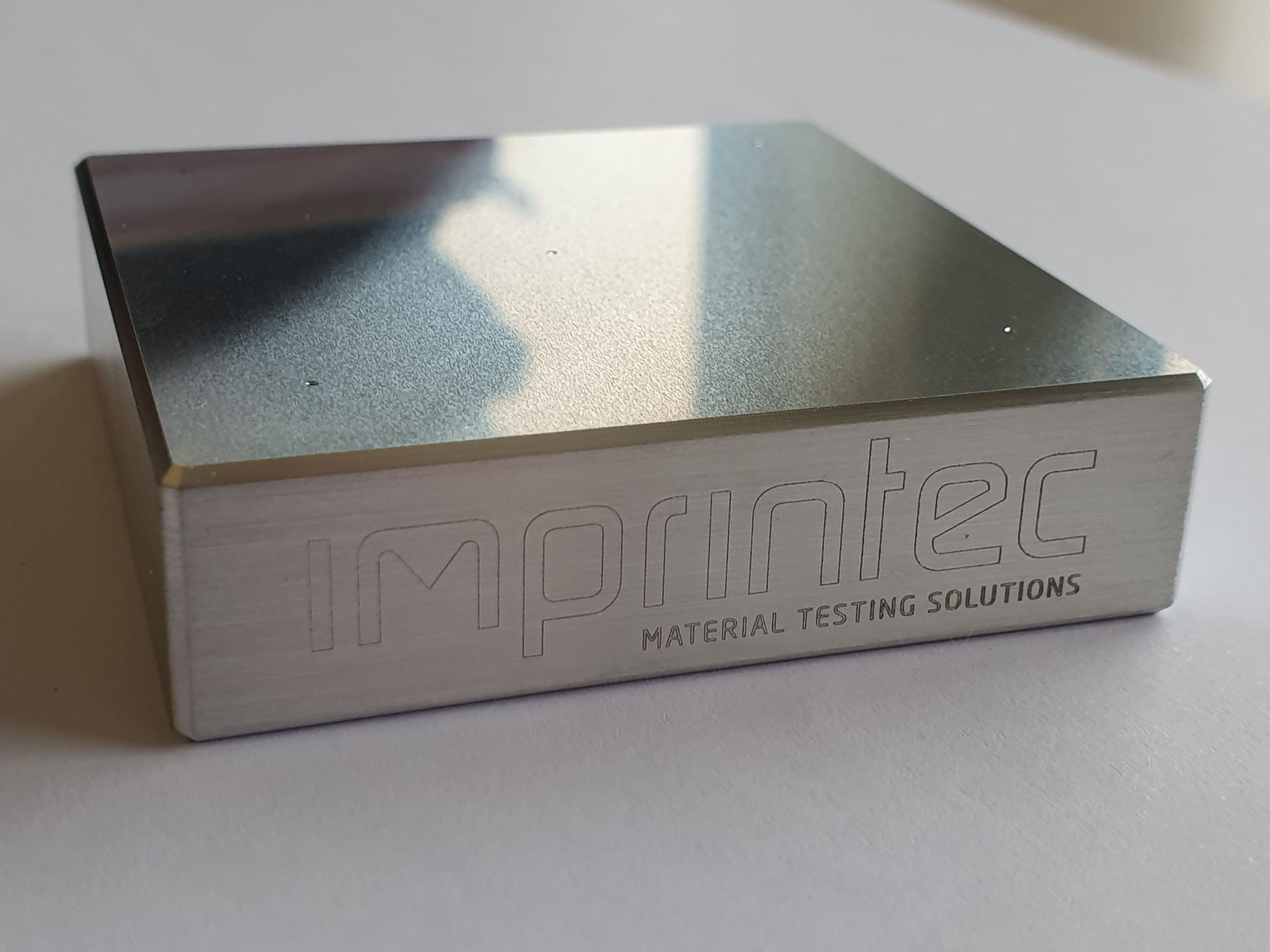

In the Imprintec materials testing laboratory, our specialists work with the innovative and patented indentation method according to DIN SPEC 4864, with which just one measuring point provides the desired mechanical characteristic values (yield strength and ultimate tensile strength).

Use of laboratory tests with imprinting methods.

In many cases, we can support you in the development and quality assurance of your components. You thus create a solution for testing your components where you have not been able to take tensile specimens so far or where the 0.2% offset yield strength and ultimate tensile strength for different metals is not covered by hardness conversion.

We invite you to experience these benefits for yourself in our materials testing laboratory. Make an appointment with us in Bochum and let us consult you on the individual advantages for your company.

Frequently asked questions about our materials testing laboratory

What added value does the indentation process offer compared to other processes?

- Low destruction

- Precise testing of the 0.2% offset yield strength and the ultimate tensile strength

- Samples with small dimensions can be tested

(sheets, layers) - Determination of local stress-strain curves as a basis for FEM simulations

Which materials can we test for you in our materials testing laboratory?

In principle, we can carry out materials testing for all metals (steel, nickel, aluminum as well as titanium and copper materials)

– Please contact us individually about the materials you want to test.

Does the sample or component have to meet certain requirements?

The sample to be tested should have the following properties:

- Component height should not be higher than 350 mm

- Top and bottom surfaces should be parallel to each other, or must be suitable for preparation. For optimum results, the inclination of both surfaces should be less than 2%

What is the range of loads that can be tested?

We can test with a wide range loads from 5kgf to 150kgf. This allows for testing on large blocks of metal to thin sheets.

Tests with individual load levels can also be conducted on request.