Component

testing.

Inspection and assurance of the component quality.

Challenge.

Tensile testing is performed as part of quality assurance in the company or materials are delivered with a test certificate in the incoming goods department. During further processing to the final product or component, the mechanical and geometrical properties change. The mechanical properties of the end product or component can usually no longer be adequately checked.

Procedure.

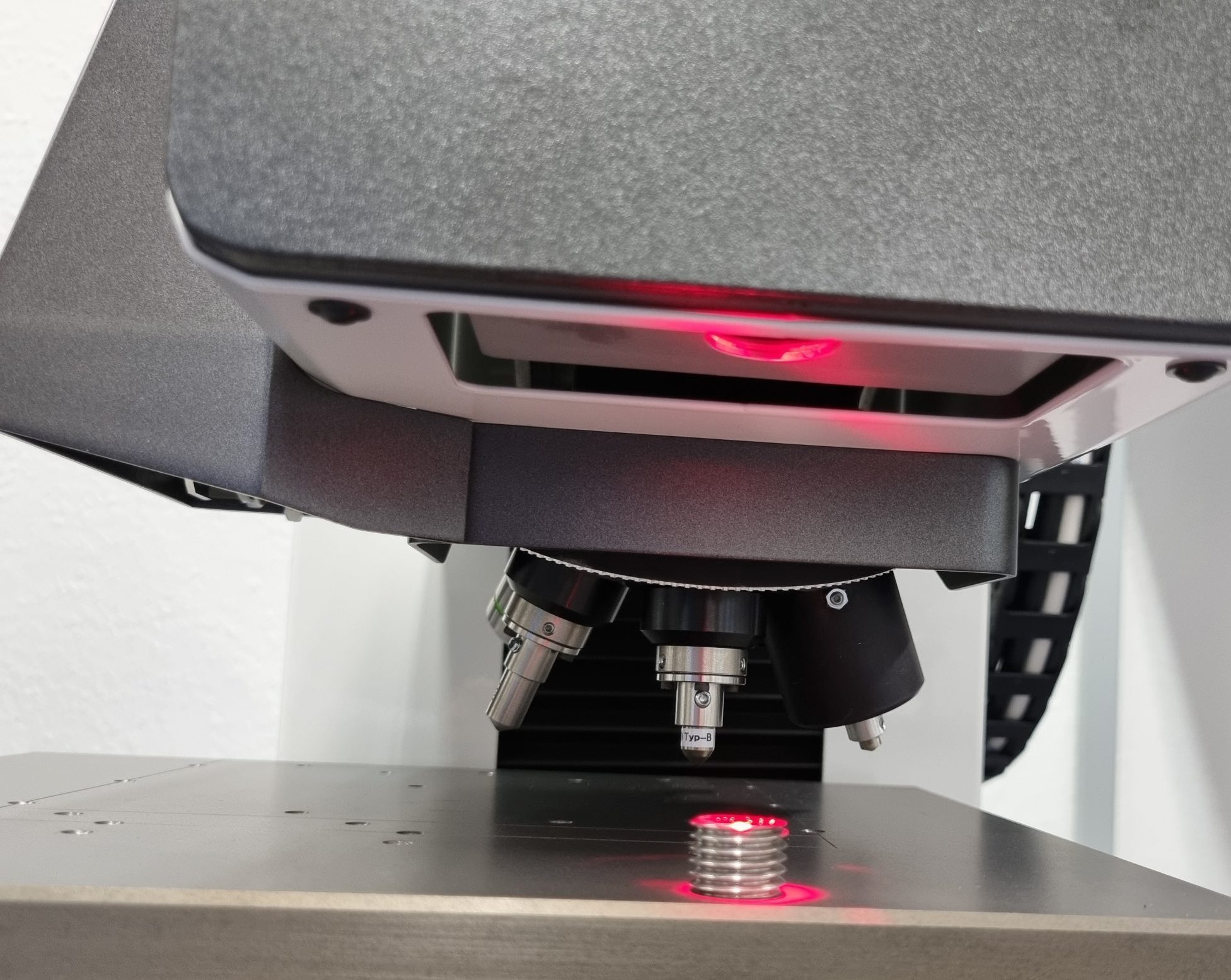

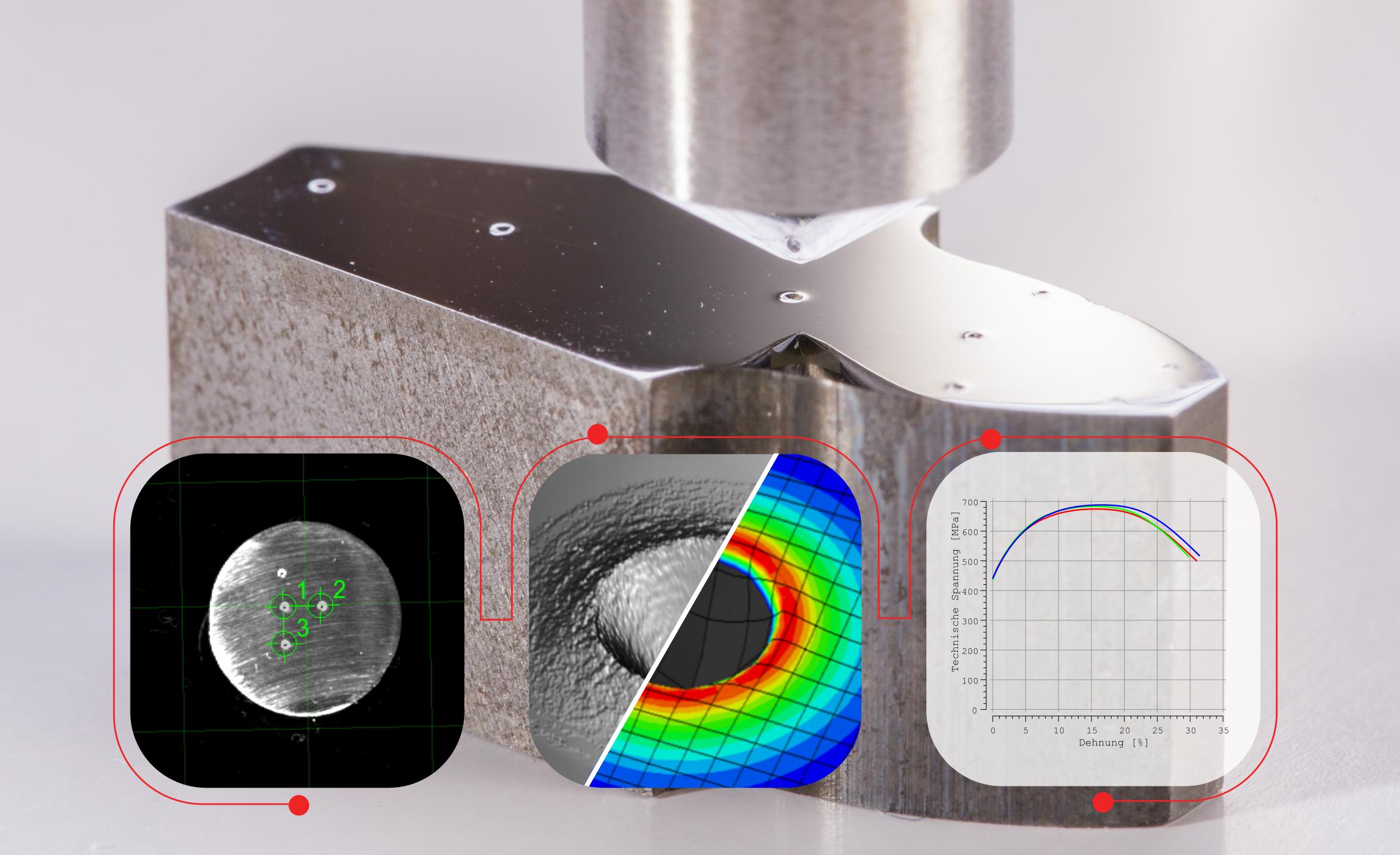

The indentation process can be applied to the final product. Together with the comparison of the initial material properties, the change in properties can be precisely quantified.

Result.

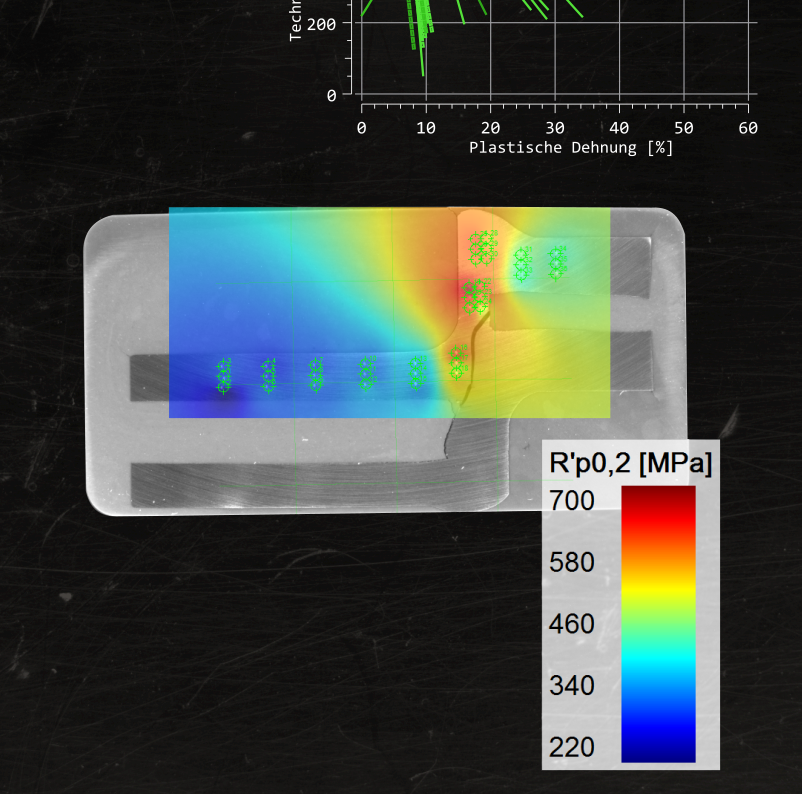

Mechanical parameters of the component are available and thus a process-oriented test is possible. Even small components that would otherwise only be accessible for a tensile test as part of a miniature tensile test can be tested close to the process. The comparison with the desired and required properties provides the result of the component quality.

Conclusion.

The component quality is checked and ensured by testing with the imprinting method. Weak points or production and batch fluctuations can be detected promptly. This ensures high and consistent component quality and early defect prevention.

Our products.

Our testing machines offer the measurement of 0.2% offset yield strength, ultimate tensile strength, ductility as well as the stress-strain curve – with conventional hardness testing on request.

FAQ.

Which materials can be tested?

We carry out comparative measurements on tensile specimens. The software is supplied with a material-optimized material model for this purpose. Verification work on new materials is carried out on an ongoing basis.